Preparation and application of ferro-nickel alloy/nitrogen-doped carbon fiber as oxygen electrocatalyst of zinc-air battery

A nitrogen-doped carbon fiber and nickel-iron alloy technology, which is applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the problem that noble metal catalysts are expensive, catalysts cannot be catalyzed at the same time, and hinder a wide range of Application and other issues, to achieve the effect of good commercial application prospects, excellent ORR catalytic activity, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

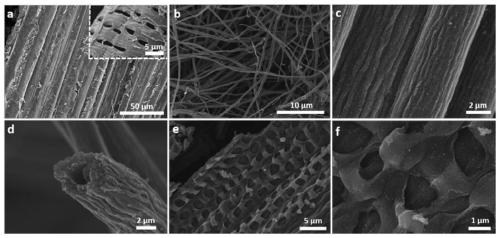

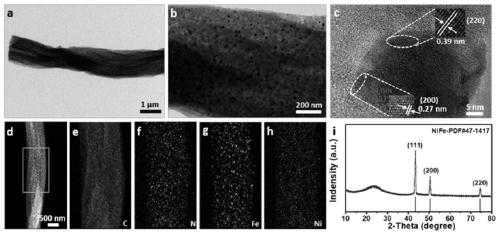

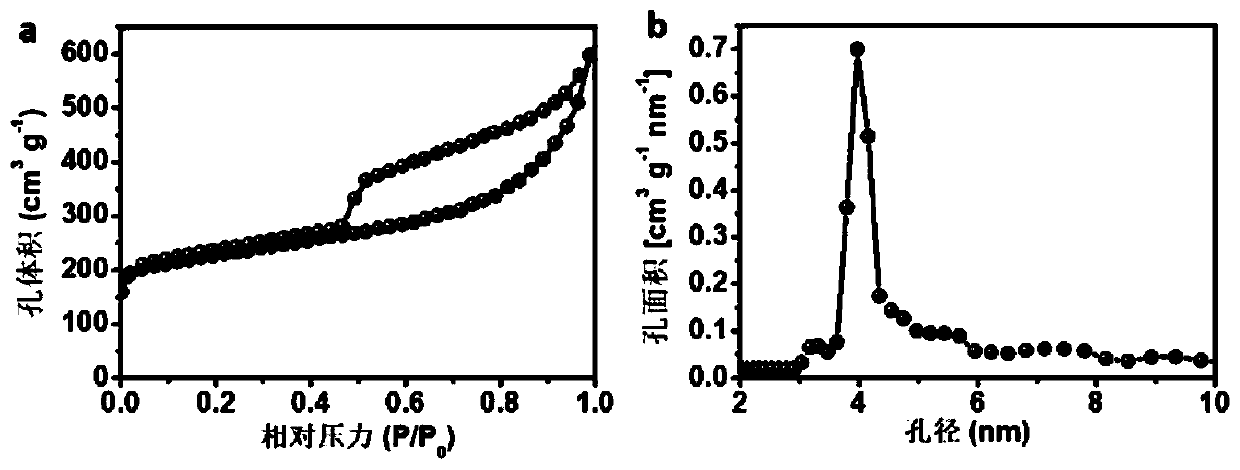

[0037] Example 1 Preparation of nickel-iron alloy / nitrogen-doped carbon fiber as oxygen electrocatalyst for zinc-air battery

[0038] (1) Rinse the discarded bamboo with deionized water, then cut it into chips with a pencil sharpener;

[0039] (2) Take 5-23.5g of potassium hydroxide and dissolve it in 70mL deionized water, stir and dissolve to form a uniform solution, the concentration of the more preferred potassium hydroxide solution is 3mol / L, and the quality taken is 11.7g;

[0040](3) Weigh 0.2-2g of bamboo chips, dissolve them in the above-mentioned potassium hydroxide solution and ultrasonicate for half an hour, then transfer them into a polytetrafluoroethylene liner for hydrothermal pretreatment, and the reaction temperature is 120-180°C , the time is 8-15h. The most preferred temperature is 150°C and the time is 12h. After the reaction is completed and the temperature is lowered to room temperature, the product is vacuum filtered to remove impurities and collected, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com