Preparation method of adipic dialdehyde

A technology of adipaldehyde and cyclohexene, which is applied in the field of preparation of adipaldehyde, can solve the problems of high price, excessive oxidation, hindering industrial application, etc., and achieve the effects of reducing production cost, high product selectivity, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0059] Preparation of Example 1-10 Molecular Sieve Supported Metal Oxide Catalyst

[0060] Dissolve a certain amount of saline solution in water, set the volume to 10mL, take 10g molecular sieve and use the equal volume impregnation method to load metal elements on the molecular sieve, then place it in an oven at 100°C for 12h, and then bake it in a muffle furnace at 500°C 4h. The types and qualities of carriers and metal salts are shown in Table 1.

[0061] The preparation parameter of table 1 catalyst

[0062] Example catalyst Metal salt type Metal salt mass (g) Molecular sieve mass (g) 1 3.0Fe / HY Fe(NO 3 ) 3 9H 2 o

[0063] Wherein, in the name of the catalyst nA / B, A represents the supported metal element, B represents the molecular sieve, and n represents the mass loading amount of the metal element A.

Embodiment 11

[0064] Example 11 Cyclohexene oxidation to adipaldehyde

[0065] In a 250mL round bottom flask, add 1.0g of cyclohexene, 0.10g of methyl pyruvate, 25mL of acetonitrile, 0.10g of 3.0Fe / HY catalyst, raise the temperature to 20°C, and feed a mixed gas with an ozone concentration of 100mg / L, The mixed gas is composed of ozone and oxygen, and the flow rate of the mixed gas is 60mL / min. After reacting for 1h, it is rapidly lowered to room temperature, and the product composition is analyzed with a gas chromatograph.

Embodiment 12-20

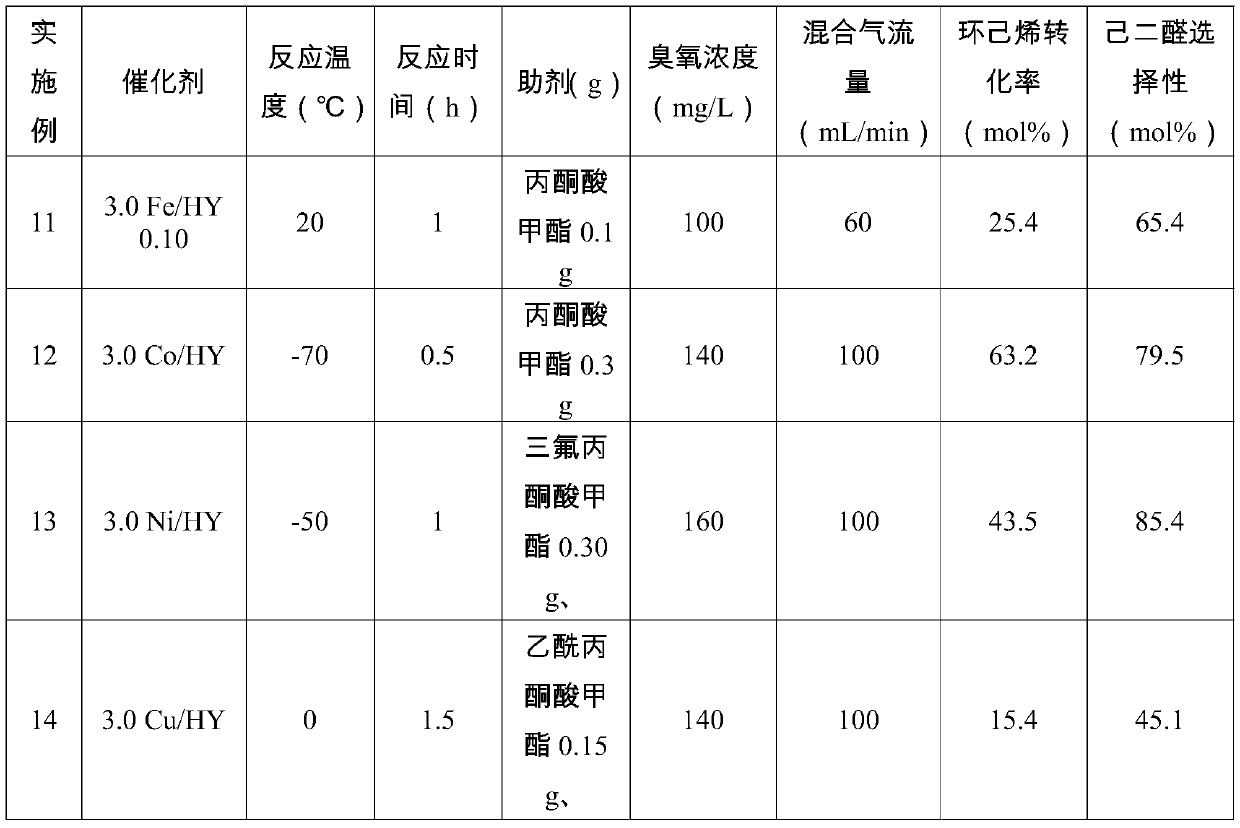

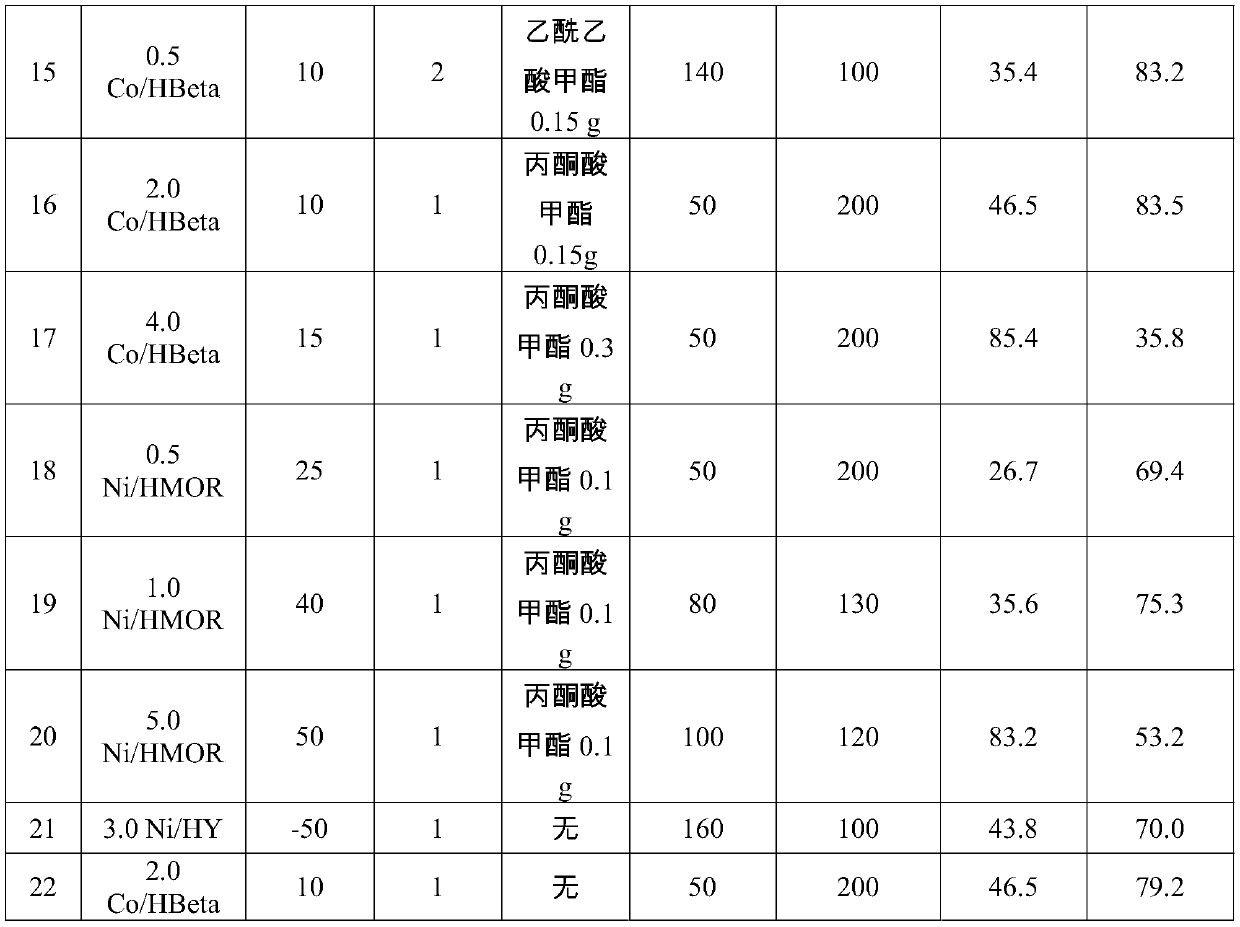

[0066] Example 12-20 Cyclohexene oxidation to adipaldehyde

[0067] The cyclohexene oxidation reaction was carried out according to the same steps as in Example 11, and the specific differences and results of the reaction conditions are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com