Pouring sealant and preparation method thereof, solar inverter and electronic component

A potting and mixing technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as water resistance defects, achieve low viscosity, good water resistance, and overcome poor water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

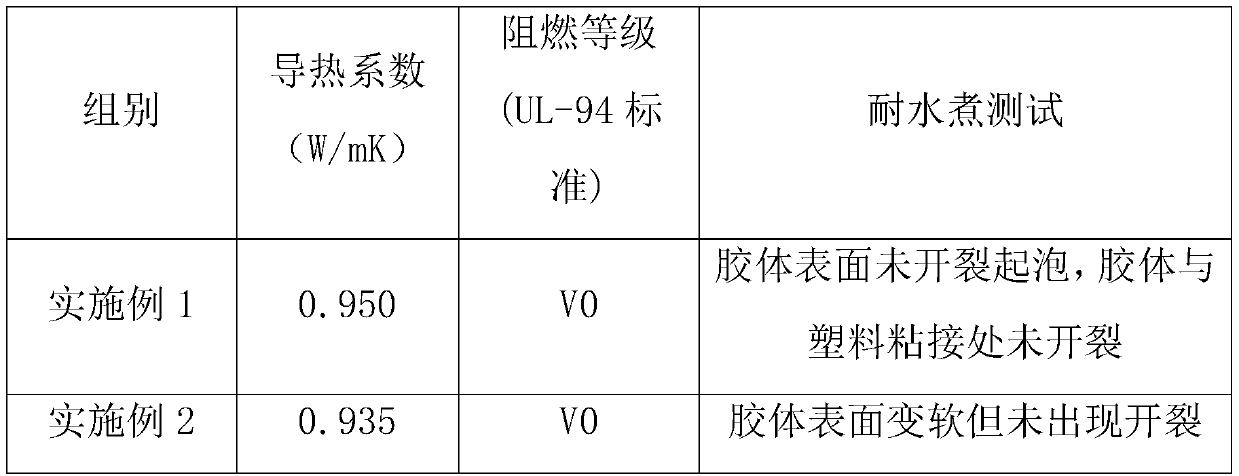

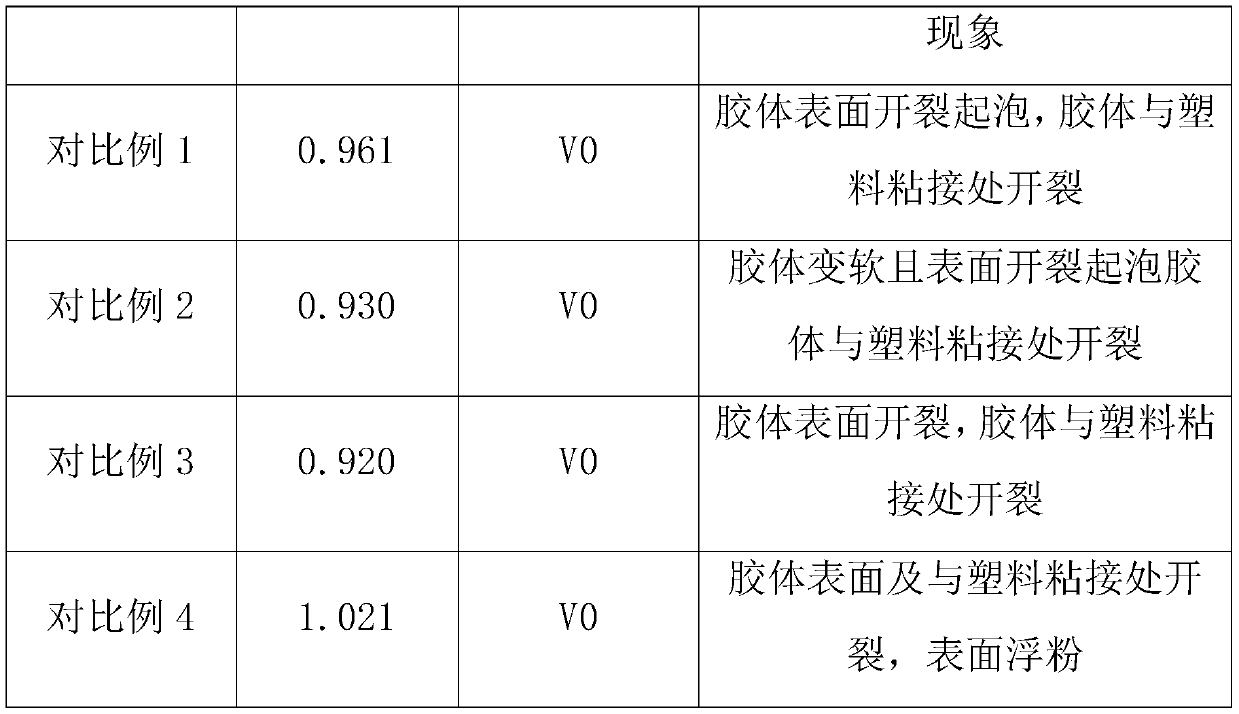

Examples

Embodiment 1

[0046] A potting glue, including A component and B component, wherein, the A component includes the following raw materials: 300g of epoxy resin (select CEL 2021P), 30g of diluent (select XY-692), 10g of auxiliary agent (Alkyl ammonium salt anti-settling agent is selected), flame retardant 80g (non-reactive flame retardant is selected), thermal conductive filler 580g (aluminum oxide is selected), hydrophobic filler 40g (polytetrafluoroethylene powder is selected), water resistance Silane coupling agent 40g (select epoxy trimethoxysilane coupling agent for use); Described B component comprises following raw material: acid anhydride curing agent 280g (select methyl hexahydrophthalic anhydride for use), accelerator 10g (select imidazoles for use to promote agent), 10g of additives (choose hydrophobic copolymer dispersant), 700g of thermally conductive filler (choose alumina).

[0047] Wherein, the preparation method of the A component is: take epoxy resin, diluent, and auxiliary ...

Embodiment 2

[0051] A potting glue, including A component and B component, wherein, the A component includes the following raw materials: epoxy resin 260g (select NPEF-170), diluent 50g (select XY-692), auxiliary agent 10g (choose alkyl ammonium salt anti-settling agent), 80g flame retardant (choose non-reactive flame retardant), 600g thermal conductive filler (choose alumina), 40g hydrophobic filler (choose polytetrafluoroethylene powder), water-resistant 40g of permanent silane coupling agent (selecting epoxy trimethoxysilane coupling agent); said B component includes the following raw materials: anhydride curing agent 250g (selecting methyl hexahydrophthalic anhydride), accelerator 10g (selecting imidazoles Accelerator), 10g of additives (choose hydrophobic copolymer dispersant), 730g of thermally conductive filler (choose alumina).

[0052] Wherein, the preparation method of the A component is: take epoxy resin, diluent, and auxiliary agent to mix, manually stir evenly, and then use a ...

Embodiment 3

[0056] A potting glue, including A component and B component, wherein, the A component includes the following raw materials: 200g of epoxy resin (select CEL 2021P), 10g of diluent (select XY-692), 5g of auxiliary agent (Alkyl ammonium salt anti-settling agent is selected), flame retardant 50g (non-reactive flame retardant is selected), thermal conductive filler 500g (alumina is selected), hydrophobic filler 10g (polytetrafluoroethylene powder is selected), water resistance Silane coupling agent 10g (select epoxy trimethoxysilane coupling agent for use); Described B component comprises following raw material: acid anhydride curing agent 200g (select methyl hexahydrophthalic anhydride for selection), accelerator 5g (select imidazoles for use to promote agent), 5g of additives (choose hydrophobic copolymer dispersant), 700g of thermally conductive filler (choose alumina).

[0057] Wherein, the preparation method of the A component is: take epoxy resin, diluent, and auxiliary agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com