Enterobacterroggenkampii and application thereof in degradation of ethylene oxide

A technology of Enterobacter rogerii and ethylene oxide, applied in the direction of bacteria, methods based on microorganisms, methods using microorganisms, etc., can solve the problems of easy explosion, increased ethylene oxide barrier, and high technical parameter control requirements , to achieve the effect of outstanding tolerance and significant degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

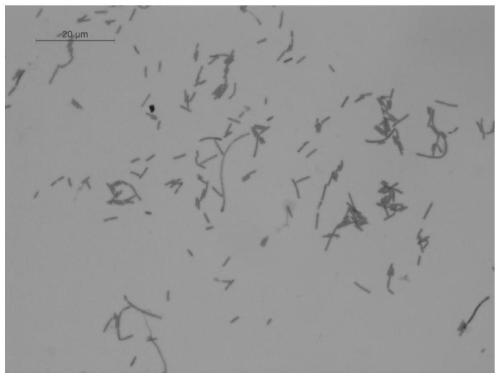

Embodiment 1

[0037] Sampling location: Sewage outlet of chemical plant in Foshan City, Guangdong Province

[0038] Sample: Sludge Mixture

[0039] Sampling amount: 10.0g

[0040]Weigh 10.0 g of the sample, add 100 mL of 0.03 mol / L phosphate buffer, mix and clarify for 120 min, and remove large particles of sediment. Draw 1mL of the suspension and add it to 10mL enrichment enrichment medium containing 100mg / L ethylene oxide, and place the inoculated enrichment medium tube and 2.5L anaerobic gas generating bag at the same time in a 2.5L round-bottom stand In a type anaerobic culture bag, seal the culture bag, place it on a shaking table for anaerobic enrichment culture at a rotation speed of 200r / min, anaerobically culture at 37°C for 24-48h, and observe the growth.

[0041] Enrichment and enrichment medium production method:

[0042] Glucose 40g, casein trypsin digest, animal tissue gastric enzyme digest and mix 10g in equal amounts, adjust pH to 5.4-5.8, add distilled water to 1000mL, d...

Embodiment 2

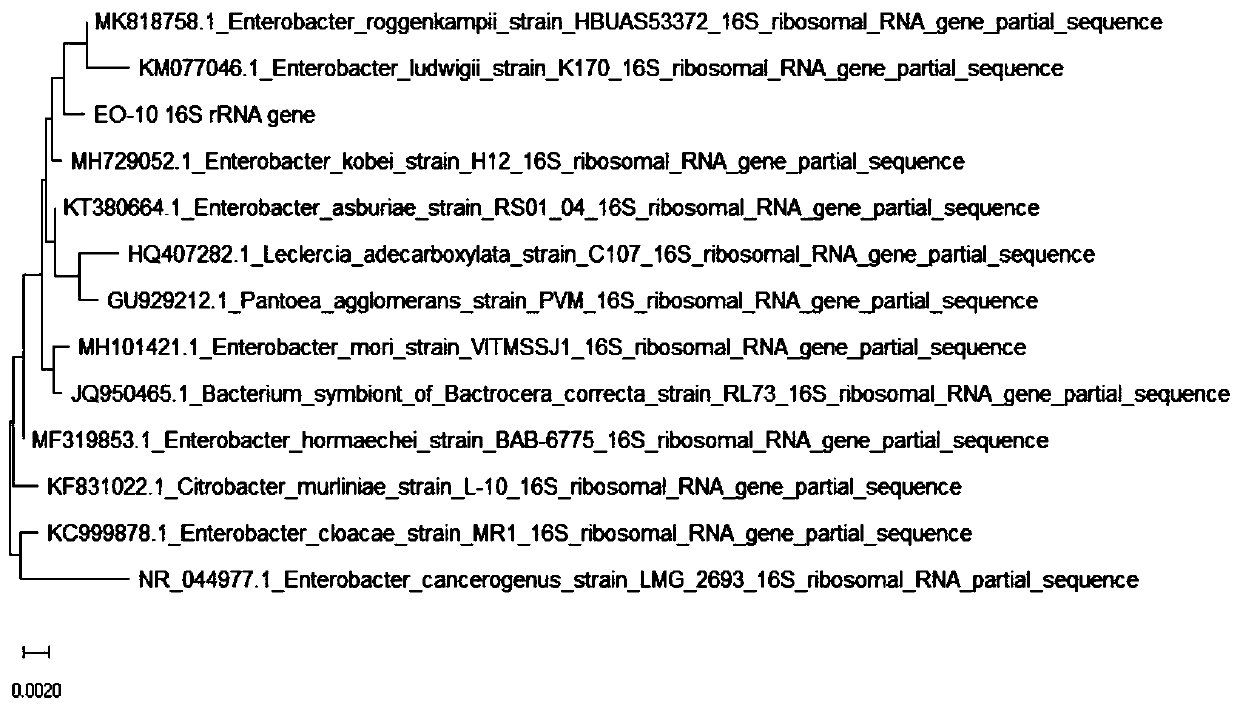

[0050] Ethylene oxide-induced domestication of the original strain EO-10

[0051] Ethylene oxide tolerance acclimatization:

[0052] Using the streaking method, inoculate the original strain of EO-10 on the ethylene oxide tolerance acclimation medium plate containing 100 mg / L ethylene oxide, and culture it anaerobically at a constant temperature at 37°C for 48 hours; select the single cell with the largest colony radius on the plate Colony, subculture to ethylene oxide tolerance acclimation medium plate containing 200mg / L ethylene oxide, 37 ℃ constant temperature anaerobic culture for 48h; select the single colony with the largest colony radius on the plate, subculture to contain 500mg / L ethylene oxide on the ethylene oxide tolerance acclimation medium plate, 37 ℃ constant temperature anaerobic culture for 48h; continue to select the single colony with the largest colony radius on the plate, subculture to 800mg / L ethylene oxide The ethylene oxide tolerance acclimation medi...

Embodiment 3

[0076] Identification of 400mg / L Ethylene Oxide Degradation Effect of EO-10 Strain

[0077] Microbial culture and activation: Take out the original EO-10 strain and EO-10 strain from the -80°C refrigerator, inoculate 10 μL into 100 mL screening purification medium, and culture anaerobically at 37°C, 200 rpm for 48 hours. The concentration of bacteria in the culture solution was 10 10 -10 12 cfu / mL.

[0078] Test group: take 5mL after activation and the concentration is 10 10 -10 12 cfu / mL EO-10 bacterial suspension, inoculated in 400mL ethylene oxide degradation force acclimation liquid medium containing no carbon source but containing 400mg / L ethylene oxide, the number of EO-10 living organisms in the medium was 10 8 -10 10 cfu / mL.

[0079] Control group 1: take 5mL after activation and the concentration is 10 10 -10 12 cfu / mL EO-10 original strain suspension, inoculated in 400mL ethylene oxide degradation force domestication liquid medium containing no ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com