Preparation method and application of Fe3O4 coating with improved thermal radiation coefficient

A heat radiation coefficient, fe3o4-tio2 technology, applied in coatings, X-ray tube parts, metal material coating process, etc., can solve the problem of low heat radiation coefficient, low heat radiation coefficient of coating, and easy peeling off of coating And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The reagents used in this embodiment are all commercially available, and the deposition equipment is an L5 electron beam physical vapor deposition (EB-PVD) equipment manufactured by the Ukrainian Paton Welding Institute.

[0051] A kind of Fe that improves thermal radiation coefficient 3 o 4 The preparation method of coating specifically comprises the following steps:

[0052] S1: Substrate processing:

[0053] S11: First polish the surface of the substrate with 2000-mesh water sandpaper to remove scale, and then polish with 2000-mesh metallographic sandpaper to remove rough scratches on the surface;

[0054] S12: Ultrasonic cleaning the substrate in acetone for 20-30 minutes to remove surface oil stains;

[0055] S13: Wash with deionized water, insert it into the card slot after air drying, and wait for coating.

[0056] S2: Material preparation:

[0057] S21: Preparation of nanoscale Fe 3 o 4 、TiO 2 :

[0058] S211: Preparation of Fe by co-precipitation metho...

Embodiment 2

[0078] Embodiment 2 is different from Embodiment 1 except that the following parts are different, and all the other contents are the same:

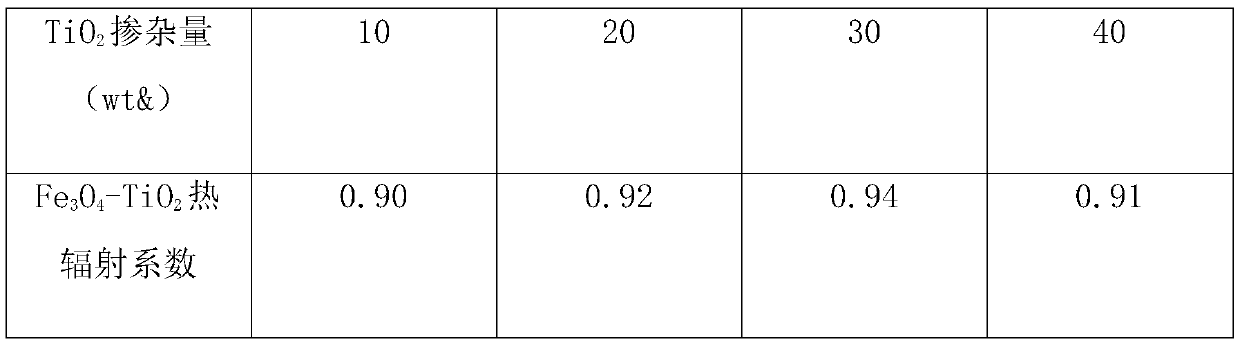

[0079] In step S23, TiO 2 Particles are mixed with magnetic Fe at a ratio of 10wt% 3 o 4 particle mixing;

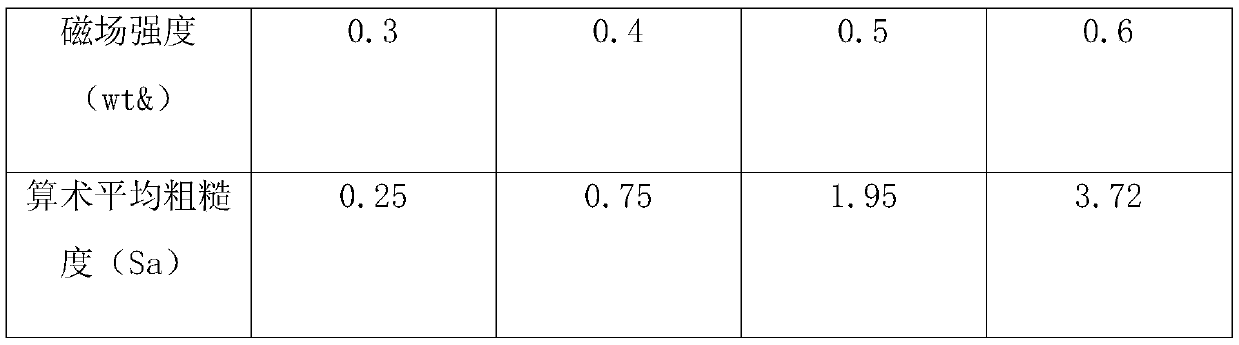

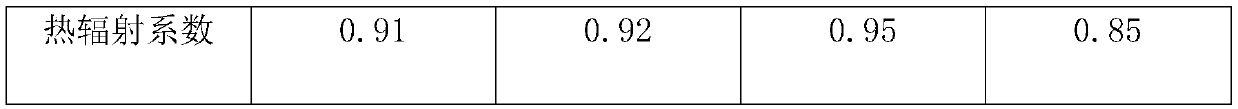

[0080] In step S322, the external uniform magnetic field=0.3Ts.

Embodiment 3

[0082] Embodiment three is different from embodiment one except the following parts, and all the other contents are the same:

[0083] In step S23, TiO 2 Particles are mixed with magnetic Fe at a ratio of 20wt% 3 o 4 particle mixing;

[0084] In step S322, the external uniform magnetic field=0.4Ts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com