High-efficiency and low-energy-consumption novel sewage deep denitrification technology and system thereof

A technology of deep denitrification and low energy consumption, applied in the field of water treatment, can solve the problems of not taking advantage of the MABR process, and achieve the effect of improving oxygen utilization rate, occupying a small area and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

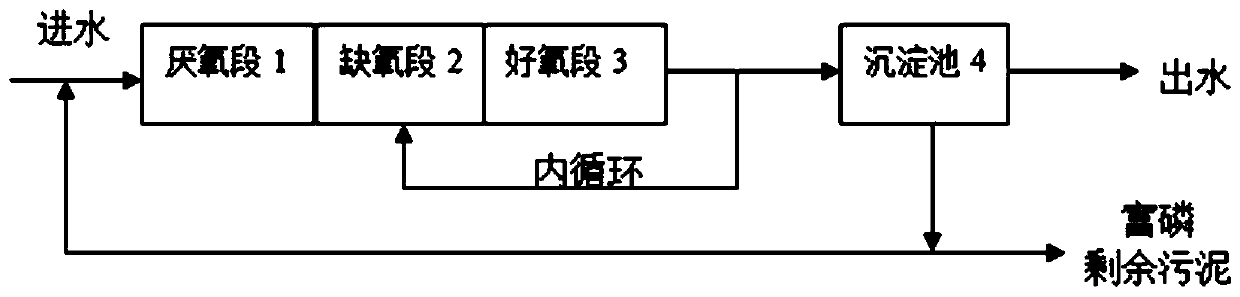

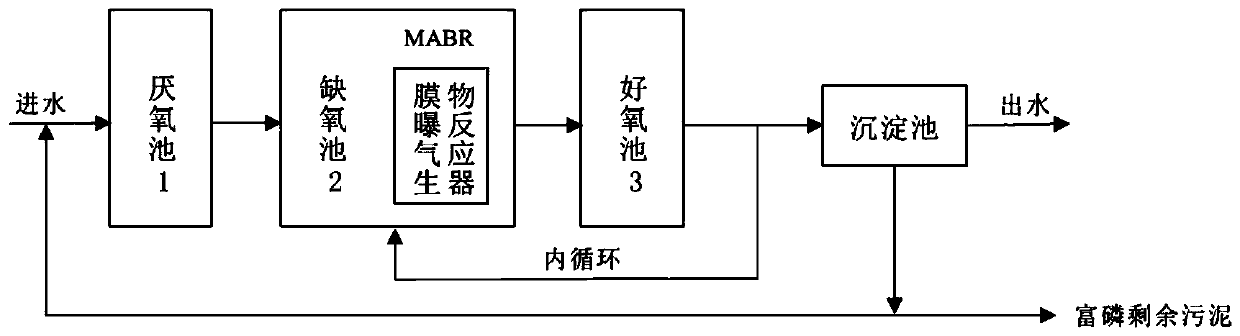

[0054] Example 1: MABR+A 1 +A 2 Combination process

[0055] according to Figure 4 The shown process flow chart establishes a MABR+A with a processing capacity of 50L / day 1 +A 2 Processing system, the parameters of the system are as follows:

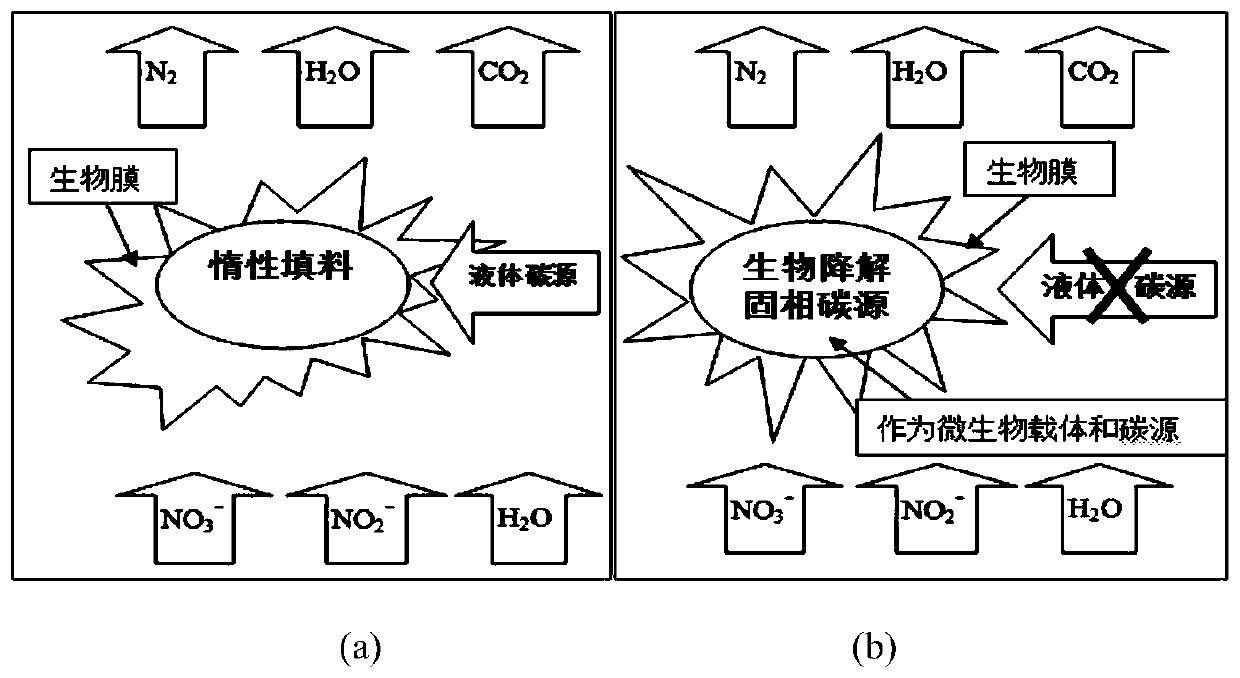

[0056] The bubble-free aeration membrane module is installed in the MABR tank, compressed air is used as the oxygen supply source, and nitrogen is used as the scrubbing gas; the height of the solid-phase carbon source filler is uniformly 25cm, and the height of the inert filler is uniformly 40cm; MABR tank, solid-phase carbon source denitrification reaction Pool A 1 , Inert packing denitrification reaction pool A 2 The hydraulic retention time of 10 hours, 15 minutes and 60 minutes respectively; denitrification reaction tank A 1 and A 2 Dissolved oxygen is controlled at 0.2-0.4mg / L; the whole process has no reflux of nitrification liquid and no sludge reflux.

[0057] Take the sludge from the sewage treatment plant and treat th...

Embodiment 1-1

[0060] The MABR tank is equipped with Zeelung bubble-free aeration membrane modules provided by Suez Water Technology (Shanghai) Co., Ltd.; denitrification reaction tank A 1 Filled with poly-3-hydroxybutyrate-valerate (PHBV) cylindrical particles (molecular weight: 360,000) produced by Ningbo Tianan Biomaterials Co., Ltd., with an average length of 4.0 mm and an average diameter of 2.5 mm; denitrification reaction tank A 2 Fill with purchased soft packing. According to the operating conditions described in Example 1, the film-hanging and water inflow were carried out to form a dense bacterial film and obtain stable COD and TN treatment effects.

Embodiment 1-2

[0062] The MABR tank is equipped with Zeelung bubble-free aeration membrane modules provided by Suez Water Technology (Shanghai) Co., Ltd.; denitrification reaction tank A 1 Fill the composite pellets of PHBV and PBS, the specific processing method is: measure 0.5 kg PHBV and 4.5 kg PBS and mix them evenly in a high mixer, add to the feed hopper of the conical twin-screw granulator, conical twin-screw granulation The temperature settings of the five zones of the machine are 90°C, 120°C, 150°C, 175°C, and 165°C respectively, and the dry pellets are made by a ring granulator and an air cooling machine; the denitrification reaction pool A 2 Fill with purchased fiber elastic filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com