Regeneration method of nickel cobalt lithium manganate positive electrode material of waste lithium ion battery

A technology of nickel-cobalt-lithium-manganese-manganate and lithium-ion batteries, which is applied in the recycling field of waste lithium-ion battery nickel-cobalt-lithium-manganese-oxide positive electrode materials, can solve the problem that it is difficult to ensure the phase and electrochemical performance of positive electrode materials, which threaten the safety of human life, Environmental hazards and other issues, to achieve the effect of reducing material costs, high recycling costs, and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

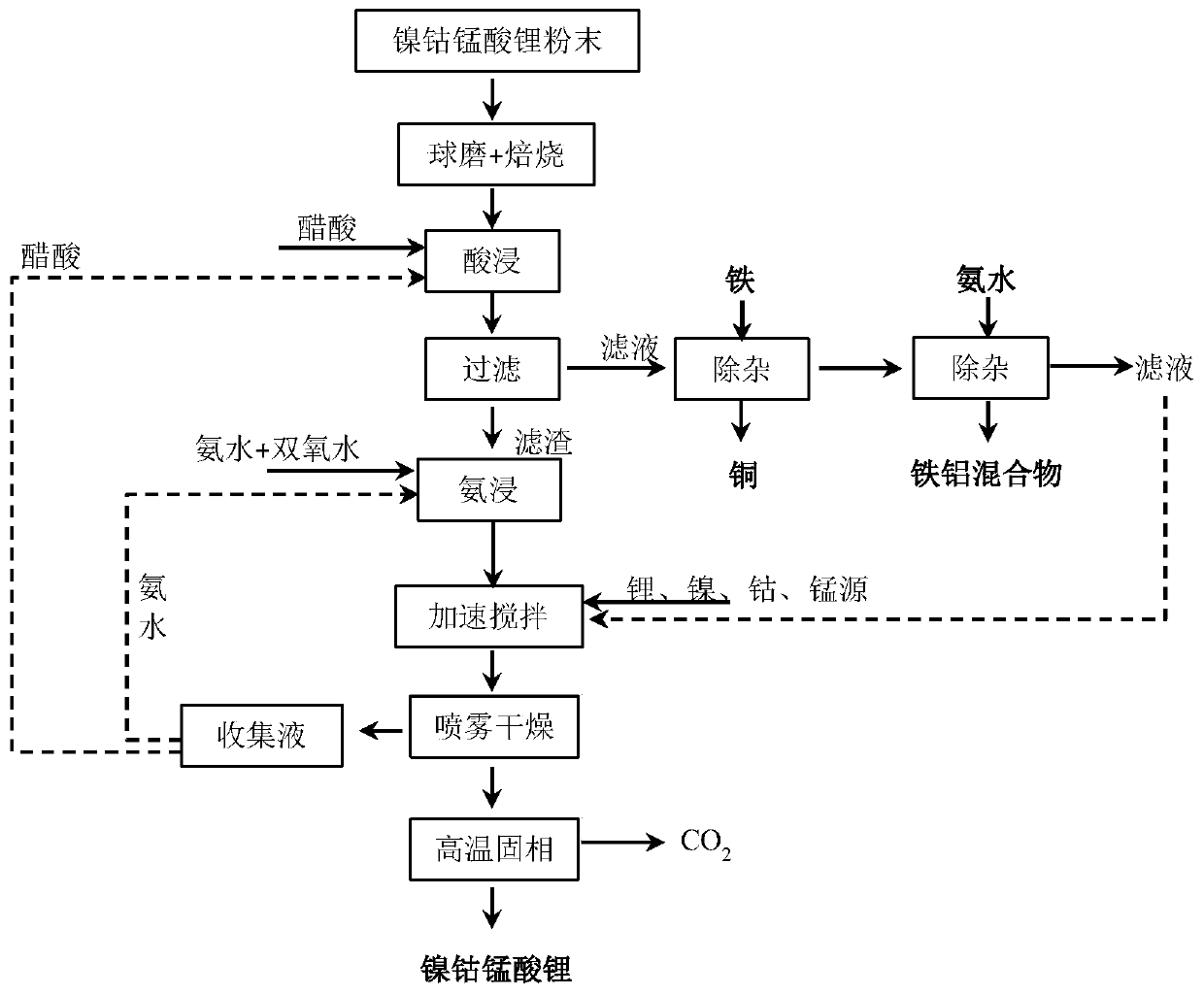

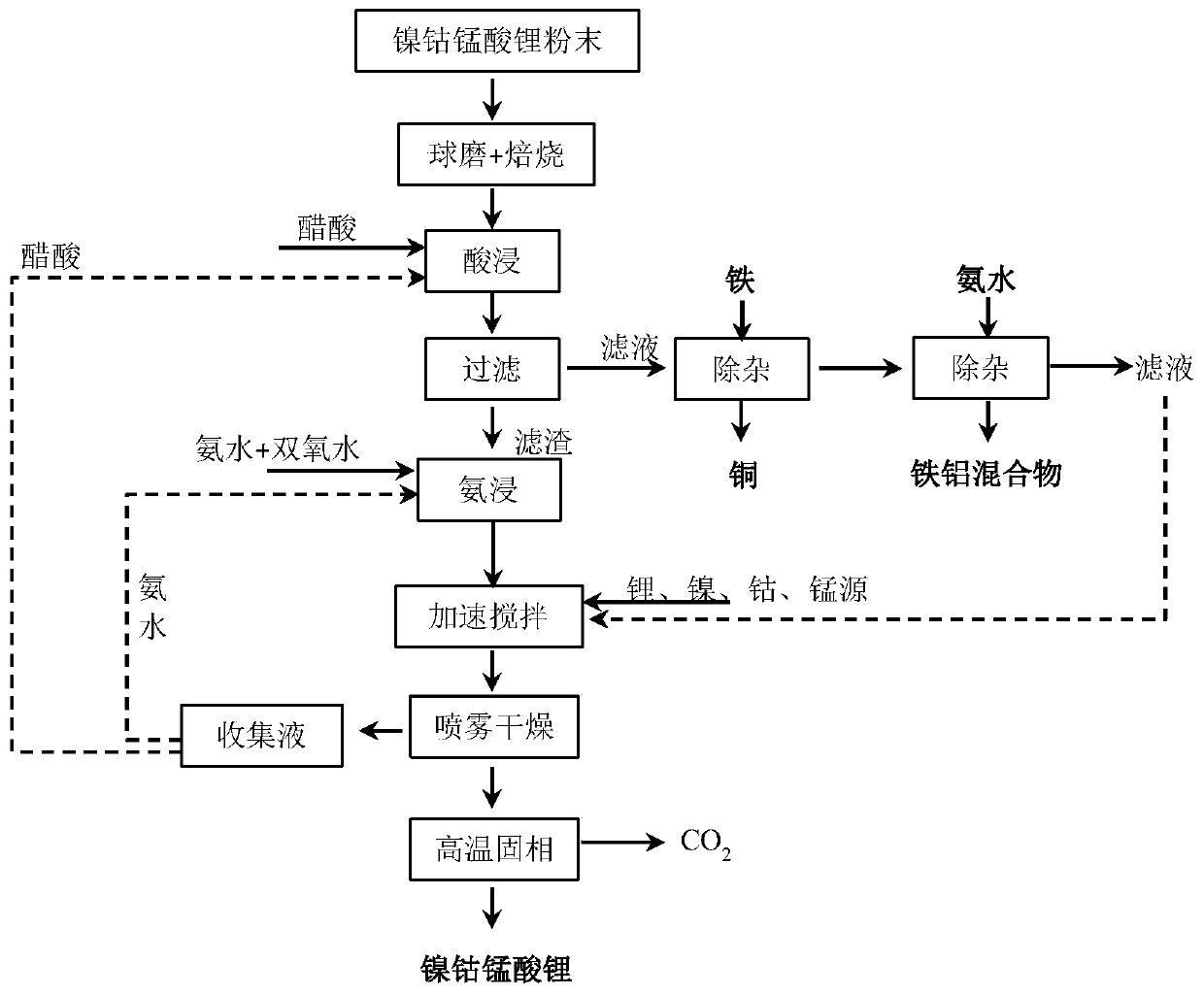

[0055] S1 The positive electrode powder obtained by peeling off the positive electrode current collector of the waste lithium-ion battery is placed in a ball mill for 2 hours and then roasted at 400°C for 4 hours in an oxygen environment to obtain a positive electrode powder with a uniform particle size below 200 mesh;

[0056] The positive electrode powder after S2 roasting is put into concentration and is 1mol / L acetic acid reaction 4h after filtering, and the solid-liquid ratio of positive electrode powder and acetic acid solution is 50g / L, obtains filter residue A and filtrate B;

[0057] S3 adds iron powder to the filtrate B, so that the molar ratio of the iron element to the copper ion is 1.05:1, reverse time 2h, filter to obtain copper, then add ammonia water to the solution, adjust the pH to 10, and then centrifuge to obtain filtrate C;

[0058] S4 put filter residue A into the mixed solution of ammonia and hydrogen peroxide, the concentration of ammonia is 6mol / L, the ...

Embodiment 2

[0068] S1 The positive electrode powder obtained by peeling off the positive electrode current collector of the waste lithium-ion battery is placed in a ball mill for 1 hour and then roasted at 500°C for 3 hours in an oxygen environment to obtain a positive electrode powder with a uniform particle size below 200 mesh;

[0069] The positive electrode powder after S2 roasting is put into concentration and is 2mol / L, and temperature is the acetic acid of normal temperature and is filtered after reaction 2h, and the solid-liquid ratio of positive electrode powder and acetic acid solution is 80g / L, obtains filter residue A and filtrate B;

[0070] S3 Add iron powder to the filtrate B so that the molar ratio of the iron element to the copper ion is 1.2:1, and filter for 1 hour to obtain copper, then add ammonia water to the solution, adjust the pH to 11, and then centrifuge to obtain filtrate C;

[0071] S4 puts the filter residue A into the mixed solution of ammonia and hydrogen per...

Embodiment 3

[0081] S1 The positive electrode powder obtained by peeling off the positive electrode current collector of the waste lithium-ion battery is placed in a ball mill for 0.5h and then roasted at 500°C for 1h in an oxygen environment to obtain a positive electrode powder with a uniform particle size below 200 mesh;

[0082] The positive electrode powder after S2 roasting is placed in acetic acid with a concentration of 2mol / L and a temperature of 30°C for 6 hours and then filtered. The solid-to-liquid ratio of the positive electrode powder and the acetic acid solution is 100g / L, and the filter residue A and filtrate B are obtained;

[0083] S3 adds iron powder to the filtrate B, so that the molar ratio of the iron element to the copper ion is 1.05:1, the reaction time is 3h, and the copper is obtained by filtration, and then ammonia water is added to the solution, and the pH is adjusted to 9.5 and then centrifuged to obtain the filtrate C;

[0084] S4 put filter residue A into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com