A catalyst for simultaneous denitration, mercury removal and dioxin removal and preparation method thereof

A technology for removing dioxins and catalysts, which is applied in flue gas purification in the field of chemical plants, simultaneous denitrification, mercury and dioxin removal catalysts and its preparation, in the field of coal-fired power plants, to achieve wide activation temperature range, high cost performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

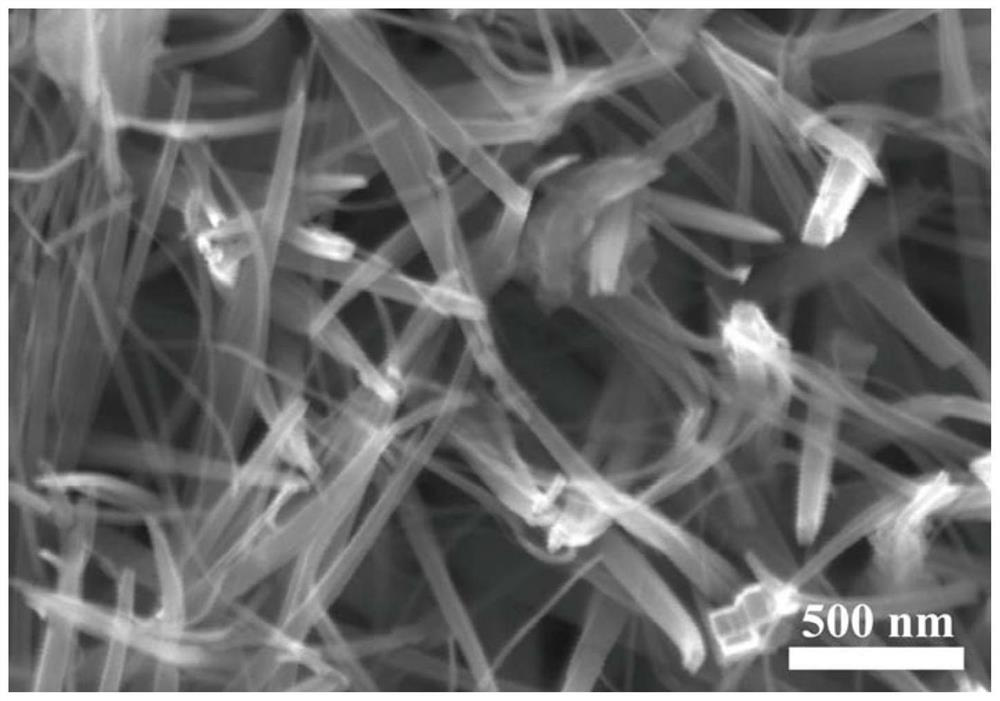

Image

Examples

Embodiment 1

[0028] (1) Preparation of active component precursor solution

[0029] Weigh 21.234g of ceric ammonium nitrate, 6.776g of niobium pentachloride and 42.015g of ascorbic acid, add 56.02g of deionized water, place it in a constant temperature water bath at 80°C and stir for 90min until the solution is clear and transparent and the viscosity reaches 4000cP, to obtain the active component precursor body solution;

[0030] (2) Co-catalyst composite colloidal solution configuration

[0031] Weigh 44.2 mg of chloroplatinic acid hexahydrate and 22.127 g of deionized water and stir to generate a chloroplatinic acid solution, then add 2.213 g of ascorbic acid and carry out stirring reaction at a temperature of 5 ° C until the colloidal solution is clear and transparent, continue to weigh 144.5mg of nickel chloride and 722.5mg of glucose were added to the solution and stirred in a constant temperature water bath at 80°C for 90min until the solution was clear and transparent and the visco...

Embodiment 2

[0040] (1) Preparation of active component precursor solution

[0041] Weigh 59.721g of ceric ammonium nitrate, 22.869g of niobium pentachloride and 123.885g of ascorbic acid, add 165.18g of deionized water and place it in a constant temperature water bath at 80°C and stir for 90min until the solution is clear and transparent and the viscosity reaches 2000cP to obtain the active component precursor body solution;

[0042] (2) Co-catalyst composite colloidal solution configuration

[0043] Weigh 66.3mg of chloroplatinic acid hexahydrate and 33.191g of deionized water and stir to generate a chloroplatinic acid solution, then add 3.319g of ascorbic acid and carry out stirring reaction at a temperature of 5 ℃ until the colloidal solution is clear and transparent, continue to weigh 216.7mg of nickel chloride and 1.084g of glucose were added to the solution and stirred in a constant temperature water bath at 80°C for 90min until the solution was clear and transparent and the viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com