Integrated sewage treatment equipment

A sewage treatment equipment, sewage technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of high investment and operation cost, small algae and difficult to separate, and secondary pollution of water quality. , to achieve the effect of promoting algae reproduction, improving disease resistance and adaptability, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

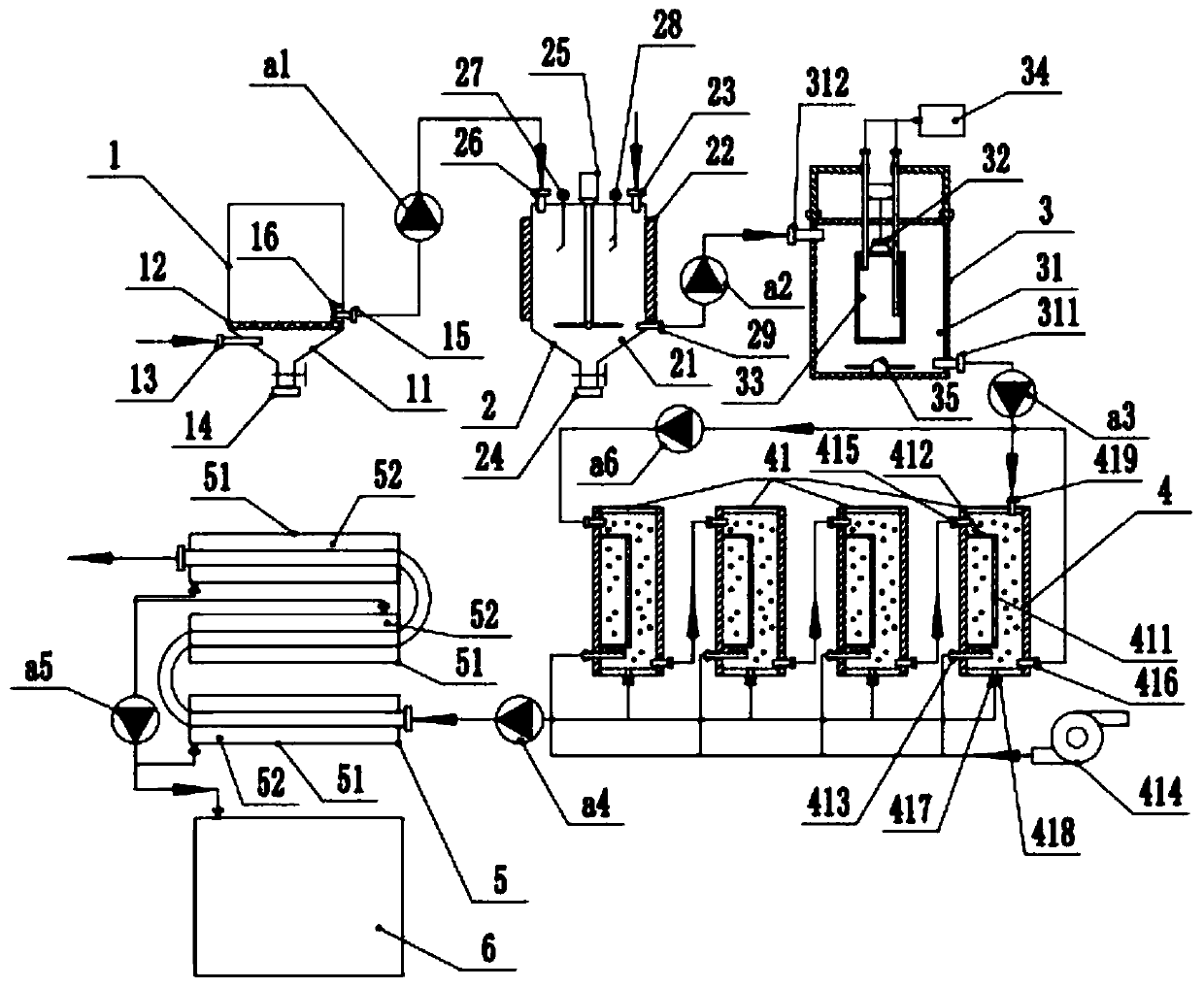

[0035] Such as figure 1 As shown, an integrated sewage treatment equipment includes: a water storage tank 1 for containing sewage. There is a water inlet 13 on one side of the water inlet 13, which is lower than the coarse grid plate 12, and is used to introduce water flow from bottom to top to intercept large solid debris under the coarse grid plate 12 to form a sedimentation area, and from the conical bucket 11 The slag outlet 14 is discharged, and the side of the water storage tank 1 is provided with a water outlet 15. The position of the water outlet 15 is higher than the coarse grid plate 12, and the fine grid plate 16 is arranged at the port of the water outlet 15 to intercept small particles in the sewage. sundries.

[0036] Such as figure 1 As shown, the coagulation and sedimentation device 2 connected to the water outlet of the water storage tank 1, the coagulation and sedimentation device 2 includes a coagulation tank 21 made of non-magnetic austenitic stainless st...

Embodiment 2

[0053] This embodiment is basically the same as Example 1, and the difference points out that the preparation method of the magnetic coagulant of the present embodiment is: according to weight components, 25 parts of chitosan powder are dissolved in 150 parts of concentration of 0.1mol / L In the silicic acid solution, to obtain chitosan acidic solution, get 6 parts of ferric oxide powder whose particle size is 15nm, 0.4 part of citric acid as dispersant, 2 parts of glutaraldehyde, 17 parts of silicone and mix to obtain Ferric iron oily dispersion, at 40°C in a water bath, gradually add the ferric iron tetroxide oily dispersion into the chitosan acidic solution dropwise with a pipette gun, and mechanically stir evenly at the same time, as the chitosan cross Under the action of glutaraldehyde of the coupling agent, it becomes magnetic chitosan gel beads, then the gel beads are transferred to saturated sodium carbonate solution and soaked for 35min, filtered, and rinsed with deioni...

Embodiment 3

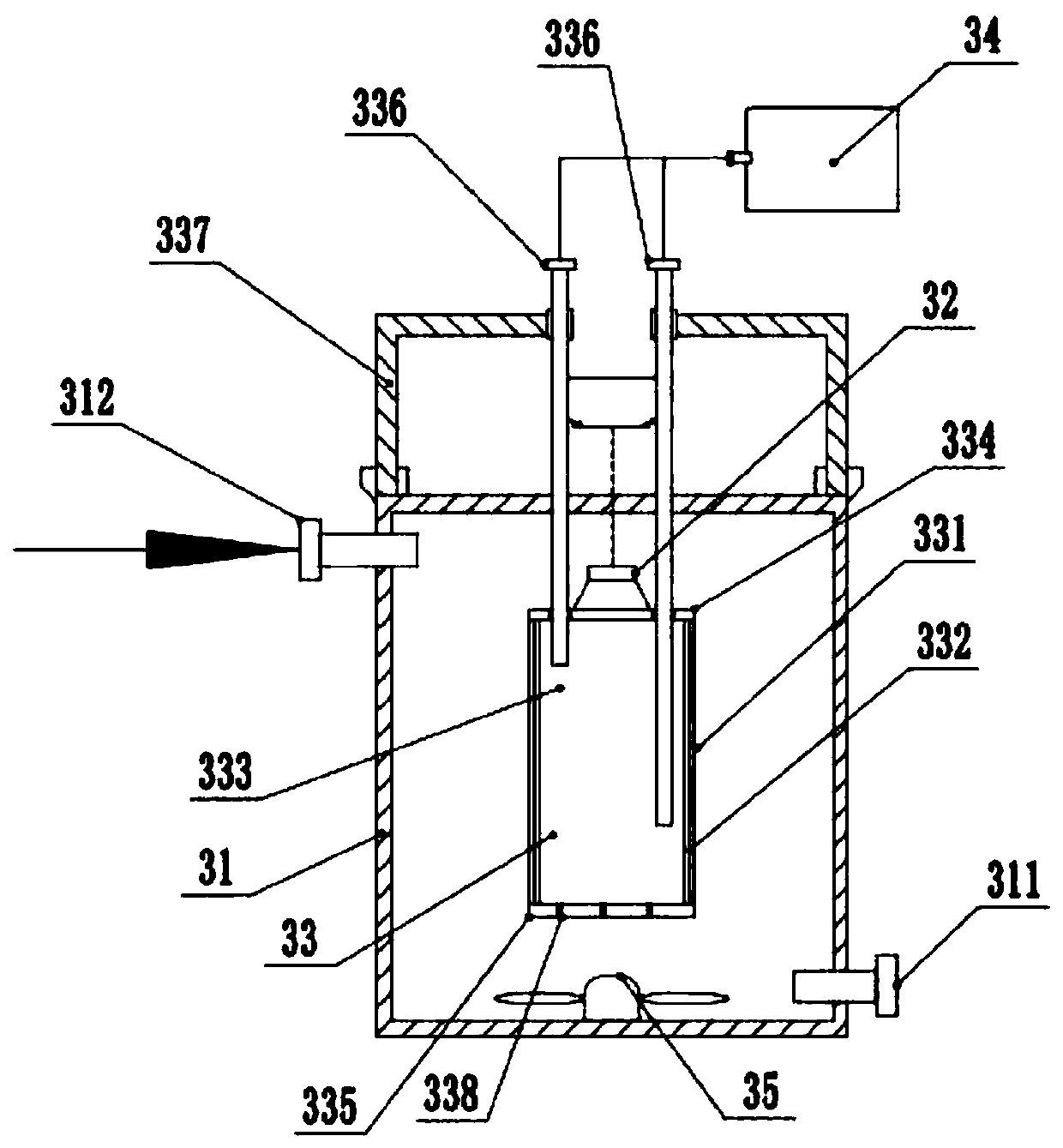

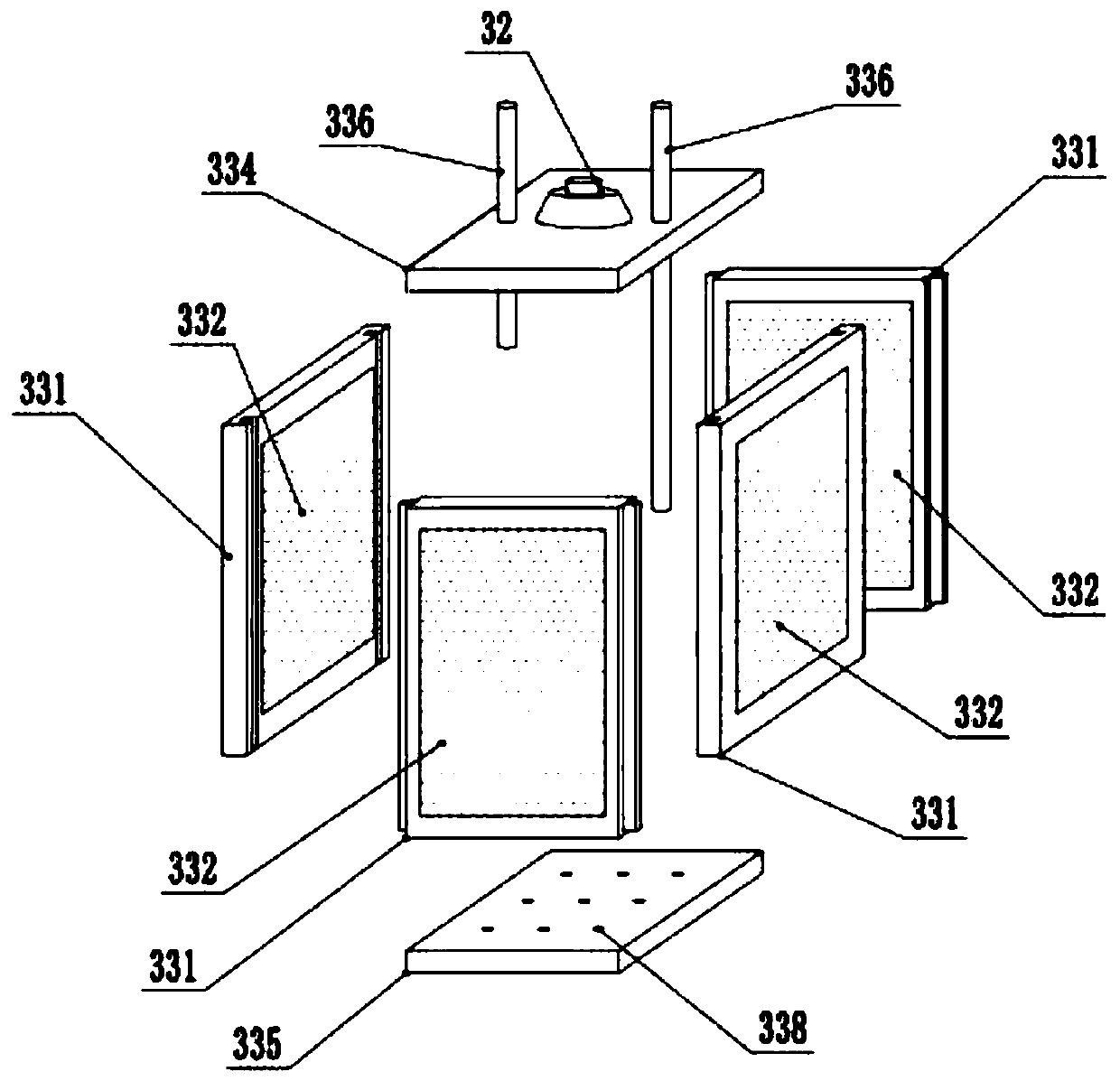

[0057] This embodiment is basically the same as Embodiment 1, the difference being that there is no plate-and-frame fiber membrane module 33 in the water storage tank 31 in the pre-demulsification device 3, but directly passes into ozone, and the ozone consumption is 0.25L / ( m 2 ·min), the running time is 25min.

[0058] The main water quality indicators of the effluent were measured, and the results were: CODCr=42-50mg / L, BOD5=4-8mg / L, SS=0mg / L, ammonia nitrogen=12-38mg / L, TN=8-15mg / L, TP< 3mg / L, the removal efficiencies are: CODCr≥94%, BOD5≥97%, ammonia nitrogen≥89%, SS=100%, TN≥93%, TP≥90%.

[0059] Comparing Example 3 and Example 1, it can be found that the CODCr, BOD5, ammonia nitrogen, and TN of Example 3 have all decreased, which may be due to the failure to achieve the desired effect in the pre-emulsification stage, resulting in subsequent algae biofilm cycle components 4 The burden is heavy, and the water quality declines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com