Force-responding polymer foam composite

A composite material and polymer technology, applied in the field of force-responsive polymer foam composite materials, can solve the problems of single structure and performance, and achieve the effect of excellent comprehensive performance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

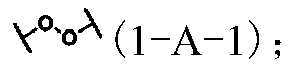

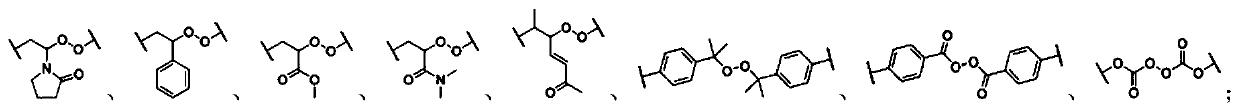

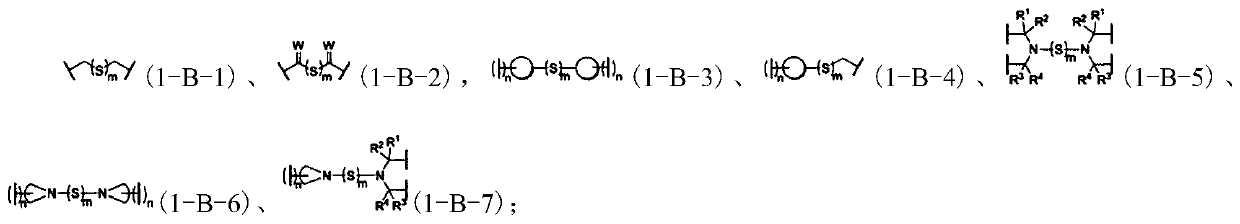

Method used

Image

Examples

preparation example Construction

[2278] In the preparation process of polymer foam particles, other optional additives are preferably antioxidants, light stabilizers, heat stabilizers, crosslinking agents, chain extenders, compatibilizers, tougheners, plasticizers, Fuel.

[2279] In the present invention, the optional fillers in the polymer mainly play the following roles: ①Reduce the shrinkage rate of the molded product, improve the dimensional stability, surface finish, smoothness and flatness or dullness of the product ②Adjust the viscosity of the polymer; ③Meet different performance requirements, such as improving the impact strength and compressive strength, hardness, stiffness and modulus of polymer materials, improving wear resistance, increasing heat distortion temperature, improving electrical conductivity and thermal conductivity Etc.; ④ Improve the coloring effect of the pigment; ⑤ Give light stability and chemical corrosion resistance;

[2280] The optional fillers include, but are not limited to...

Embodiment 1

[2328]

[2329] The thermoplastic polyurethane particle (685A, Germany BASF) of 100 weight parts, the water of 400 weight parts, the tricalcium phosphate of 7 weight parts join in the autoclave, inject the supercritical carbon dioxide of 40 weight parts under the state of stirring, then Raise the temperature of the autoclave to 116°C, keep the pressure in the autoclave at 20 bar, then maintain the temperature and pressure for 2 hours, and finally open the discharge valve at the bottom of the autoclave, take out the foam particles, wash and air dry.

[2330] Take 8g of hexamethylene diisocyanate and add it to a three-necked flask, vacuum dehydrate it at 120°C for 2 hours, add 12ml of DMF to dissolve and dilute after cooling down to 45°C, protect it with argon, then mix 3.5g of the force-sensitive compound (a) and A small amount of butyl tin ethyl dilaurate solution was dissolved in 40 mL DMF and added dropwise to the reaction flask at a constant speed. After heating to 70 ° C...

Embodiment 2

[2333]

[2334] Using equimolar amounts of 2-aminoethylaminoboronic acid and dopamine as raw materials and tetrahydrofuran as a solvent, carry out condensation reaction at 50°C and pH=8 to obtain amino compound (b). An isocyanate compound containing tetrathiafulvalene is prepared by reacting equimolar amounts of triphenylmethane triisocyanate with 4-hydroxymethyl-tetrathiafulvalene.

[2335] Weigh 30g of polyetheramine 2,000 and 2.5g of amino compound (b) in a dry and clean flask, heat to 100°C to remove water and oxygen with nitrogen gas for 1h, then add 17g of tetrathiafulvalene-containing isocyanate compound, at 80 ℃ under the condition of nitrogen protection for 2 hours to prepare the modified polyurea, which was cut into uniform granules. Then take the polyurea particle of 100 weight parts, the water of 400 weight parts, the tricalcium phosphate of 7 weight parts join in the autoclave, inject the supercritical carbon dioxide of 40 weight parts under the state of stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com