Nickel-cobalt-manganese multi-metal@ graphitized carbon@ hierarchical pore porous carbon material and preparation and application thereof in lithium-sulfur battery

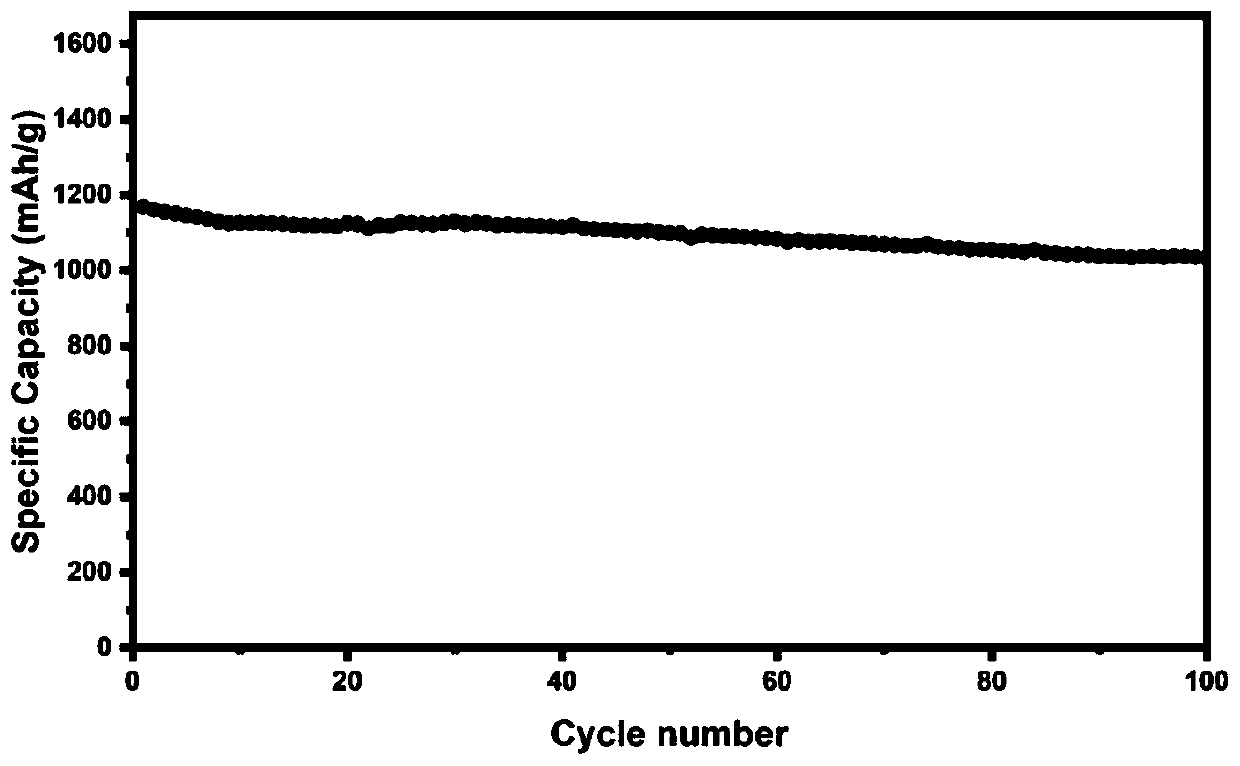

A porous carbon material, graphitized carbon technology, which is applied in lithium batteries, carbon preparation/purification, battery electrodes, etc., can solve the problems of high sulfur loading and low liquid sulfur ratio, and achieve high capacity and high cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

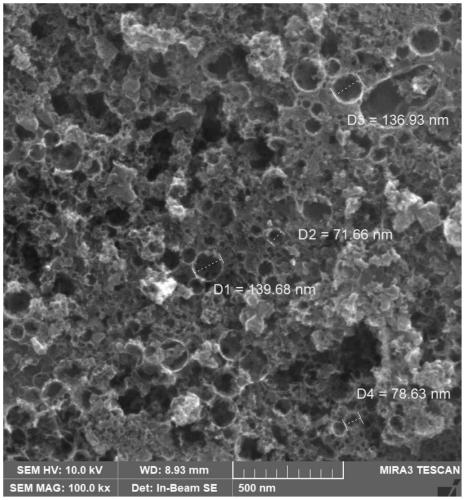

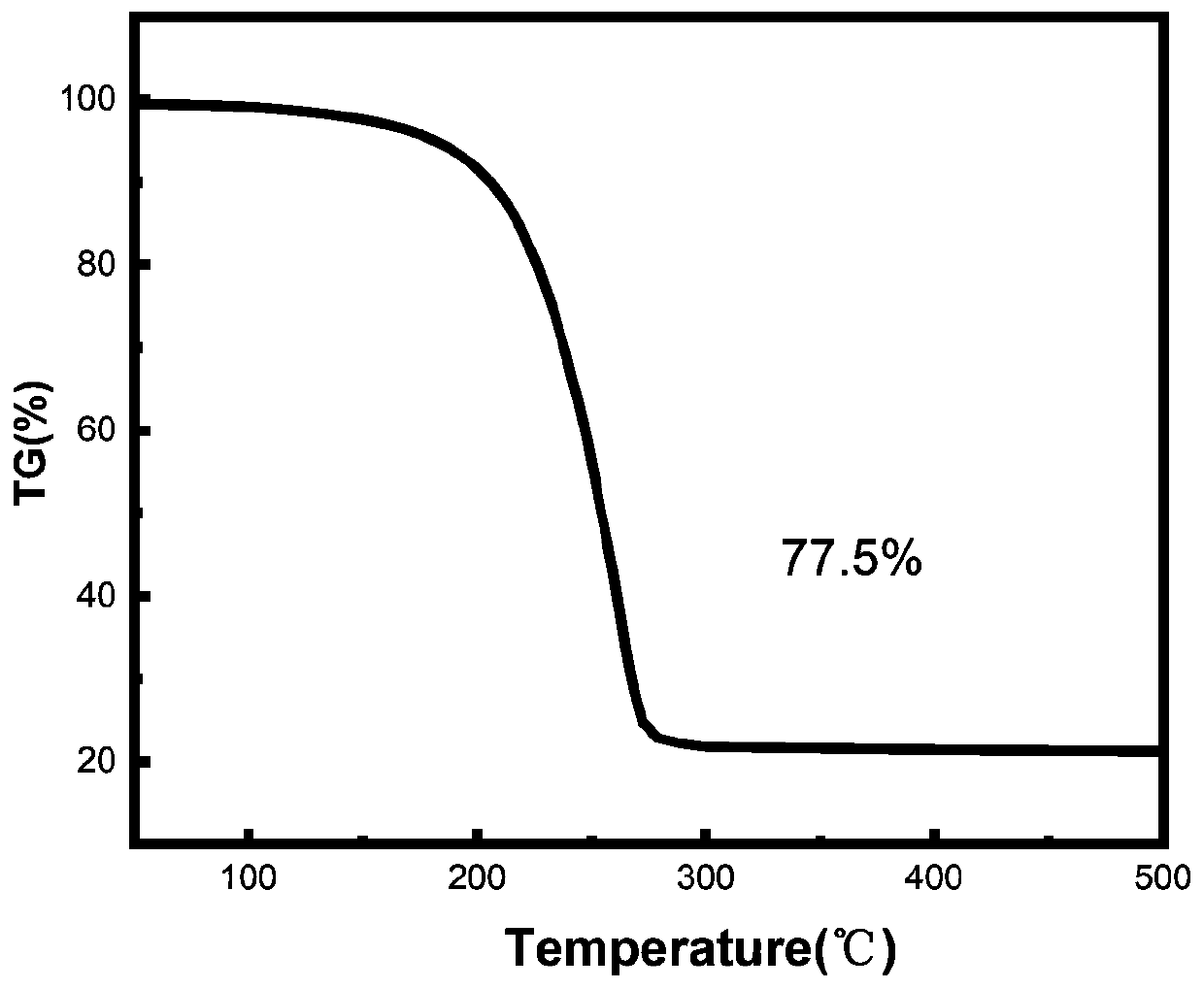

[0081] The waste ternary power battery LiNi 0.5 co 0.2 mn 0.3 o 2 Disassemble, take out the positive electrode side, peel off the ternary active material from the current collector, dry it and crush it, heat-treat 4 kg of the crushed powder at 600°C for 3 hours in an oxygen atmosphere, and add the obtained powder to 20L0. 01M dilute acid can be processed under 350rpm high-energy stirring for 5 hours to obtain nano-spherical particles. The main particle size range is 10-200nm measured by laser particle size. When the pH of the solution is close to neutral, add 50g of PVP to obtain the ternary nano-sphere dispersion. Mix 5 kg of ternary nanosphere dispersion with 5 kg of starch, stir evenly in a planetary ball mill, and control the stirring temperature at 80 degrees Celsius. After the slurry was dried at 120°C, it was carbonized in a nitrogen carbonization furnace at 1200°C for 3 hours; after the product was crushed and sieved, the ternary nano-template was washed away with 0...

Embodiment 2

[0084] Compared with Example 1, the only difference is that the waste ternary power battery LiNi is used 0.6 co 0.2 mn 0.2 o 2 Batteries are treated as follows:

[0085] The waste ternary power battery LiNi 0.6 co 0.2 mn 0.2 o 2 Disassemble, take out the positive electrode side, strip the ternary active material from the current collector, dry it and break it, heat-treat 4 kg of the broken powder at 600°C for 3 hours in an oxygen atmosphere, and add a certain amount of the obtained powder 0.01M dilute acid (20L) can be treated with 350rpm high-energy stirring for 5 hours to obtain nano-spherical particles, and when the pH of the solution is close to neutral, add 50g of PVP to obtain a ternary nano-sphere dispersion. Mix 5 kg of ternary nanosphere dispersion with 5 kg of starch, stir evenly in a planetary ball mill, and control the stirring temperature at 80 degrees Celsius. After the slurry was dried at 120°C, it was carbonized in a nitrogen carbonization furnace at 12...

Embodiment 3

[0088] Compared with Example 1, the only difference is that the waste ternary power battery LiNi is used 1 / 3 co 1 / 3 mn 1 / 3 o 2 Batteries are treated as follows:

[0089] The waste ternary power battery LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Disassemble, take out the positive electrode side, strip the ternary active material from the current collector, dry it and break it, heat-treat 4 kg of the broken powder at 600°C for 3 hours in an oxygen atmosphere, and add a certain amount of the obtained powder 0.01M dilute acid (20L) can be treated with 350rpm high-energy stirring for 5 hours to obtain nano-spherical particles, and when the pH of the solution is close to neutral, add 50g of PVP to obtain a ternary nano-sphere dispersion. Mix 5 kg of ternary nanosphere dispersion with 5 kg of starch, stir evenly in a planetary ball mill, and control the stirring temperature at 80°C. After the slurry was dried at 120°C, it was carbonized in a nitrogen carbonization furnace at 1200°C for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com