a kind of ni/nio/ni 3 the s 2 Catalyst and its preparation method and application

A catalyst, sodium hydroxide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as rare literature reports of organic dyes, and achieve improved photocatalytic properties, simple preparation methods, good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

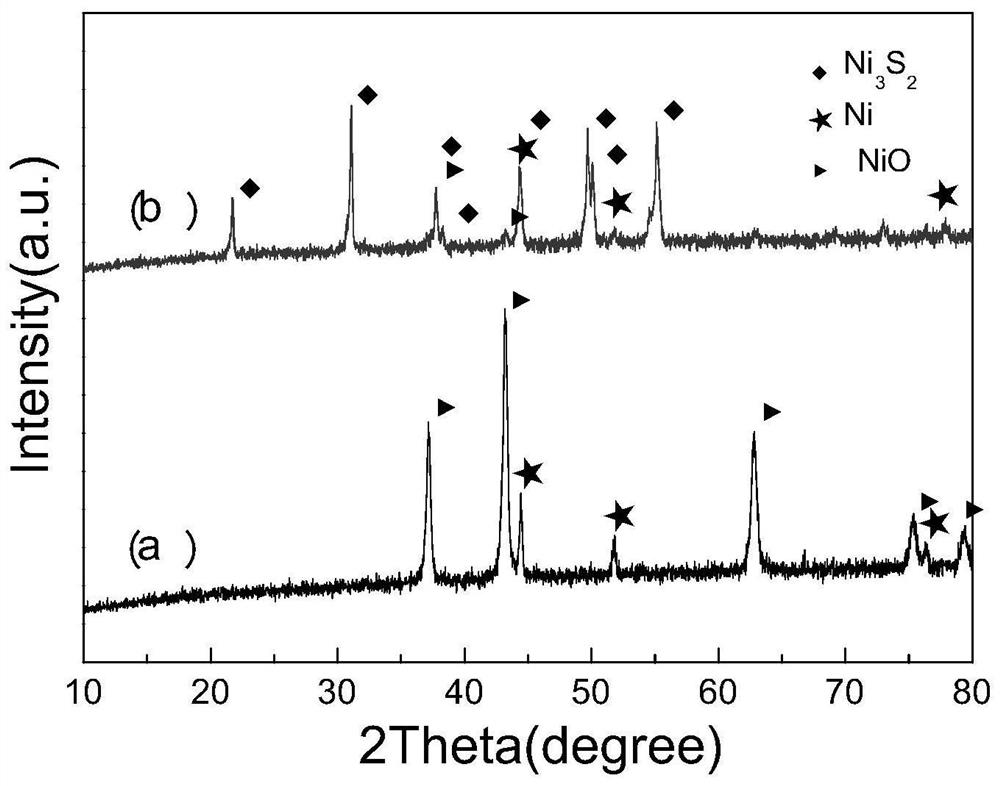

[0066] Embodiment 1, a kind of Ni / NiO / Ni 3 S 2 The preparation method of nanometer catalyst comprises steps as follows:

[0067] (1) Measure 0.7mL oleic acid in a mortar, add 0.2908g (10mmol) nickel nitrate hexahydrate and 0.1200g (30mmol) sodium hydroxide in sequence, and grind until fully reacted; repeat the above steps for a total of 10 times, grind After 1.5 h, a green solid was obtained.

[0068] Total consumption in step (1): oleic acid is 7mL, nickel nitrate hexahydrate is 2.9081g, sodium hydroxide is 1.2001g, and the molar ratio of nickel nitrate hexahydrate and sodium hydroxide=1:3.

[0069] (2) Add 65 mL of deionized water to the green solid obtained in step (1), stir well, transfer to the reaction kettle, and react at 180°C for 8 hours; the obtained precipitate is washed alternately with ethanol and deionized water for 5 The second time, after drying at 80°C for 24h, it was fired in a muffle furnace at 500°C for 2h to obtain Ni / NiO powder.

[0070] The Ni / NiO pr...

Embodiment 2

[0077] Embodiment 2, Ni / NiO / Ni prepared by the method described in embodiment 1 3 S 2 Catalyst, experimental step (1) and experimental step (2) remain unchanged, the Ni / NiO powder quality that the step (2) that takes in experimental step (3) makes constant, promptly fixed mass is 0.1074g, other physical quantities no change. The differences are:

[0078] In step (3), respectively weigh 0.1074g of Ni / NiO powder and 0.1074g of sodium sulfide nonahydrate (the mass ratio of Ni / NiO to sodium sulfide nonahydrate=1:1) prepared in step (2), add 30mL of ionized water, stirred for 15min, then ultrasonically dispersed for 1h, and the mixed solution was transferred to a microwave instrument for 60min; the filtered precipitate was washed alternately with ethanol and deionized water for 3 times, and dried at 80°C for 24h to obtain Ni / NiO / Ni 3 S 2 Powder.

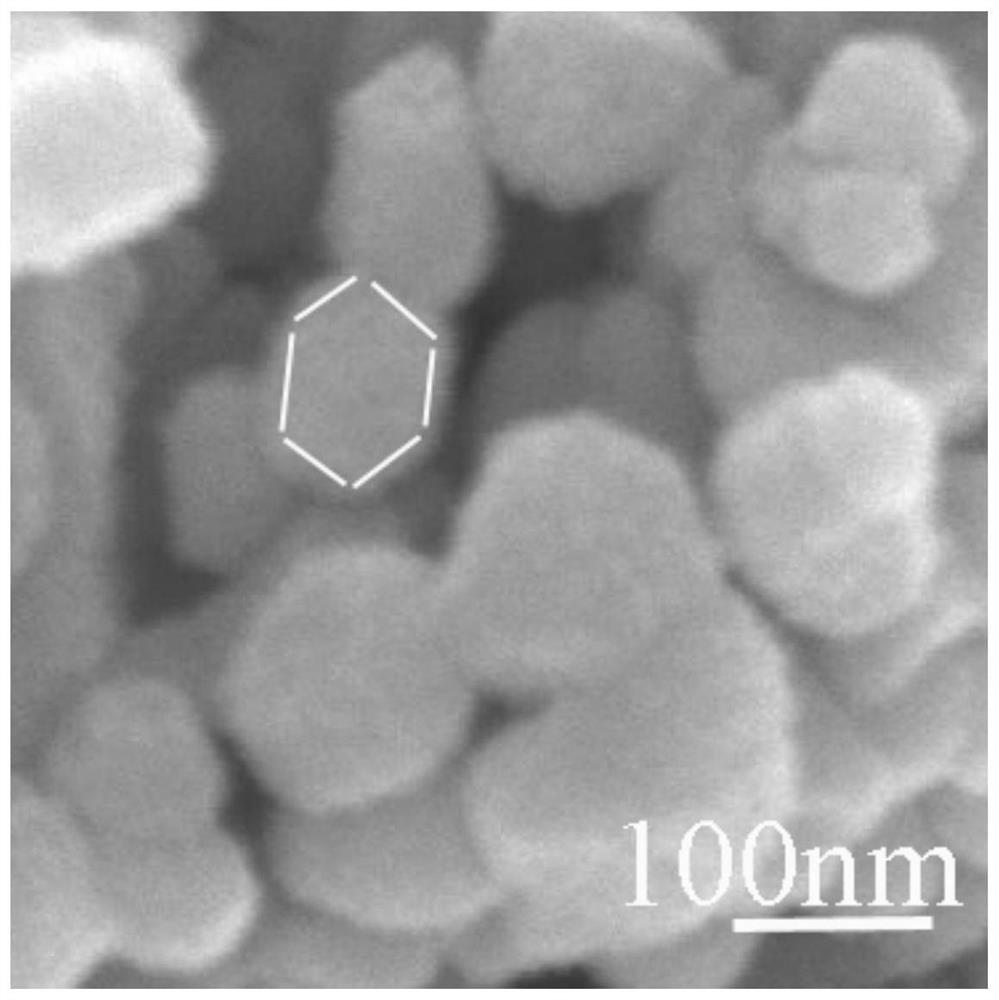

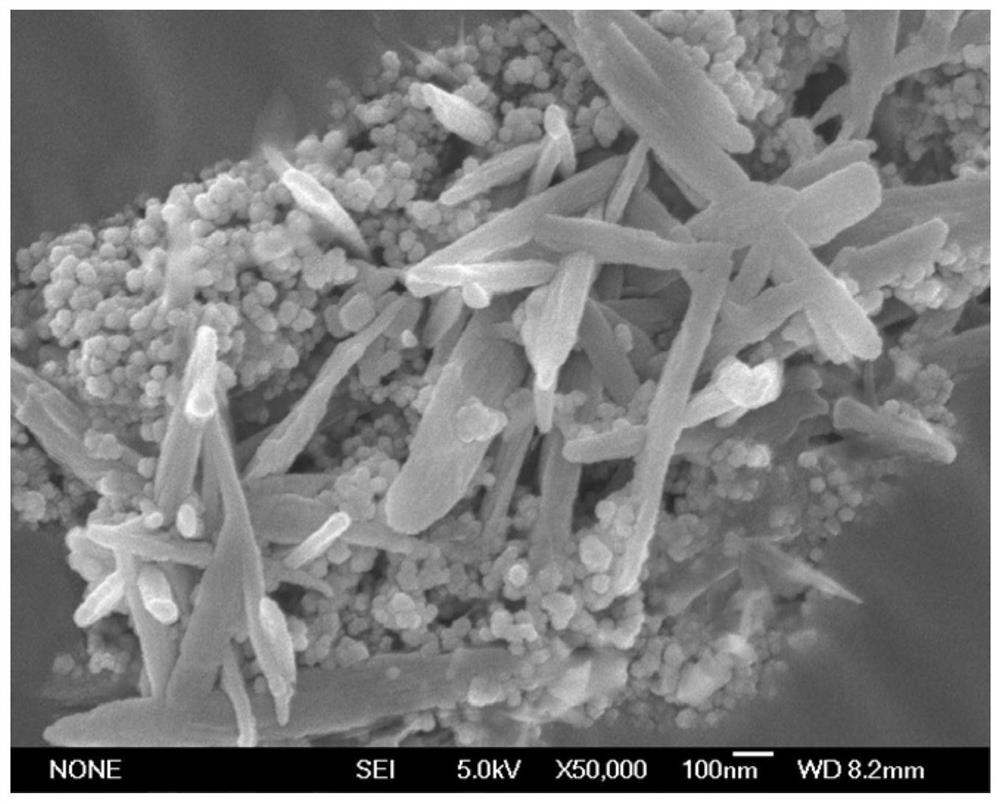

[0079] The Ni / NiO / Ni that embodiment 2 prepares 3 S 2 The composite material is composed of nanoparticles with a diameter of 10nm...

Embodiment 3

[0081] Embodiment 3, Ni / NiO / Ni prepared by the method described in embodiment 1 3 S 2 Catalyst, experimental step (1) and experimental step (2) remain unchanged, the Ni / NiO powder quality that the step (2) that takes in experimental step (3) makes constant, promptly fixed mass is 0.1074g, other physical quantities no change. The differences are:

[0082] In step (3), respectively weigh 0.1074g of Ni / NiO powder and 0.2148g of sodium sulfide nonahydrate (the mass ratio of Ni / NiO to sodium sulfide nonahydrate=1:2) prepared in step (2), add to Ionized water 40mL, stirred for 15min, and then ultrasonically dispersed for 2h, the mixed solution was transferred to a microwave instrument for 80min reaction; the filtered precipitate was washed alternately with ethanol and deionized water for 5 times, and dried at 80°C for 24h to obtain Ni / NiO / Ni 3 S 2 Powder.

[0083] The Ni / NiO / Ni that embodiment 3 prepares 3 S 2 The composite material is composed of nanoparticles with a diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com