Method for preparing high-purity graphite from natural crystalline graphite

A technology of crystalline graphite and high-purity graphite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of limited application scope of production conditions, increased production cost of electricity, and high requirements for equipment operation, and achieves purification. The process is simple and easy to operate, the reaction process is sufficient, and the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

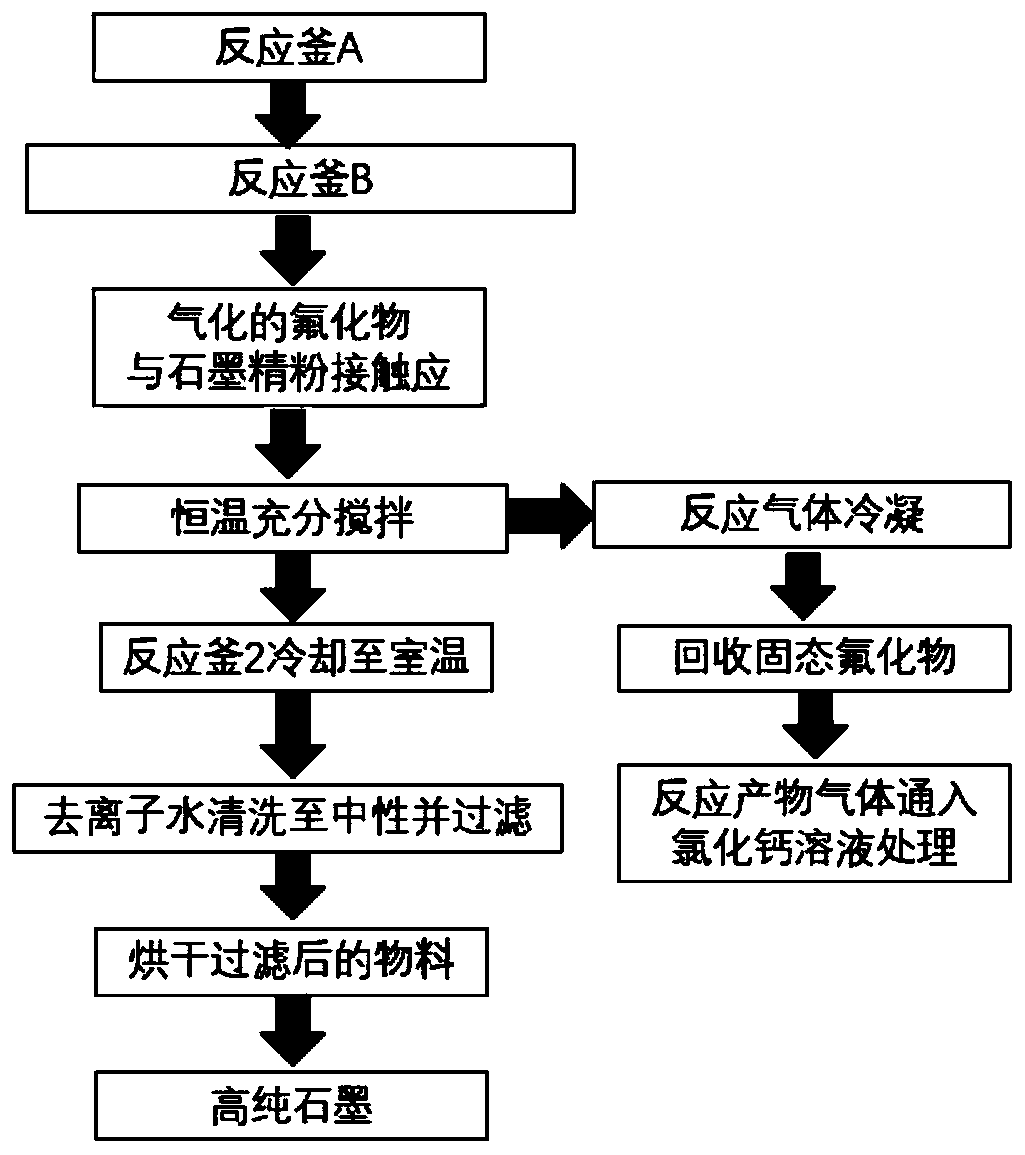

[0046] Such as figure 1 Shown, a kind of method adopting natural crystalline graphite to prepare high-purity graphite may further comprise the steps:

[0047] 1), calcium fluoride is put into reactor A, natural graphite fine powder is packed in reactor B, the particle size of described natural graphite fine powder is 280-300 order;

[0048] 2) Heat the reaction kettle A at a temperature of 300-310°C. The gas after heating and gasification is passed into the reaction kettle B to contact with natural graphite fine powder for gas-solid reaction. At the same time, the reaction kettle B is heated and heated. The temperature is 260-270°C, the reaction time of the gas-solid reaction is controlled at 80-100 minutes, the reaction kettle B is provided with a stirring device, and the natural graphite fine powder is stirred during the gas-solid reaction, so that the natural graphite The fine powder is in full contact with the gas to increase the reaction speed;

[0049] 3) After the gas...

Embodiment 2

[0051] This embodiment is based on Example 1, and the difference with Example 1 is that the particle size of the natural graphite fine powder is 260-280 mesh; A reactor is heated, and the heating temperature is 320-330 ° C; The heating temperature is 270-280° C., and the reaction time is controlled within 60-80 minutes, and high-purity graphite powder with a purity of 99.9%-99.99% can also be obtained.

Embodiment 3

[0053] The present embodiment is based on embodiment 1, and the difference from embodiment 1 is that the particle size of the natural graphite fine powder is 200-240 mesh; A reactor is heated, and the heating temperature is 340-350 ° C; The heating temperature is 290-300° C., and the reaction time is controlled within 30-40 minutes, and high-purity graphite powder with a purity of 99.9%-99.99% can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com