A kind of radial negative gradient aluminum foam sandwich panel and preparation method thereof

A technology of radial gradient and foamed aluminum, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low strength, limitations, and influence on the popularization and application of uniform foamed aluminum sandwich panels, and achieve The effect of improving the protection effect, good density, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

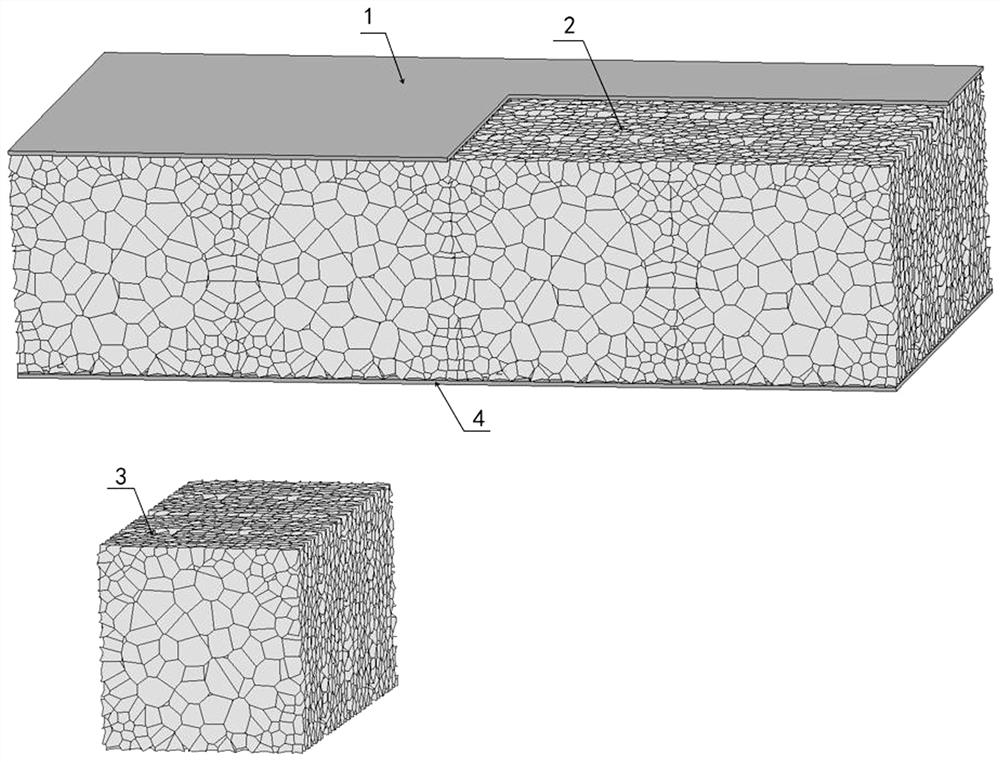

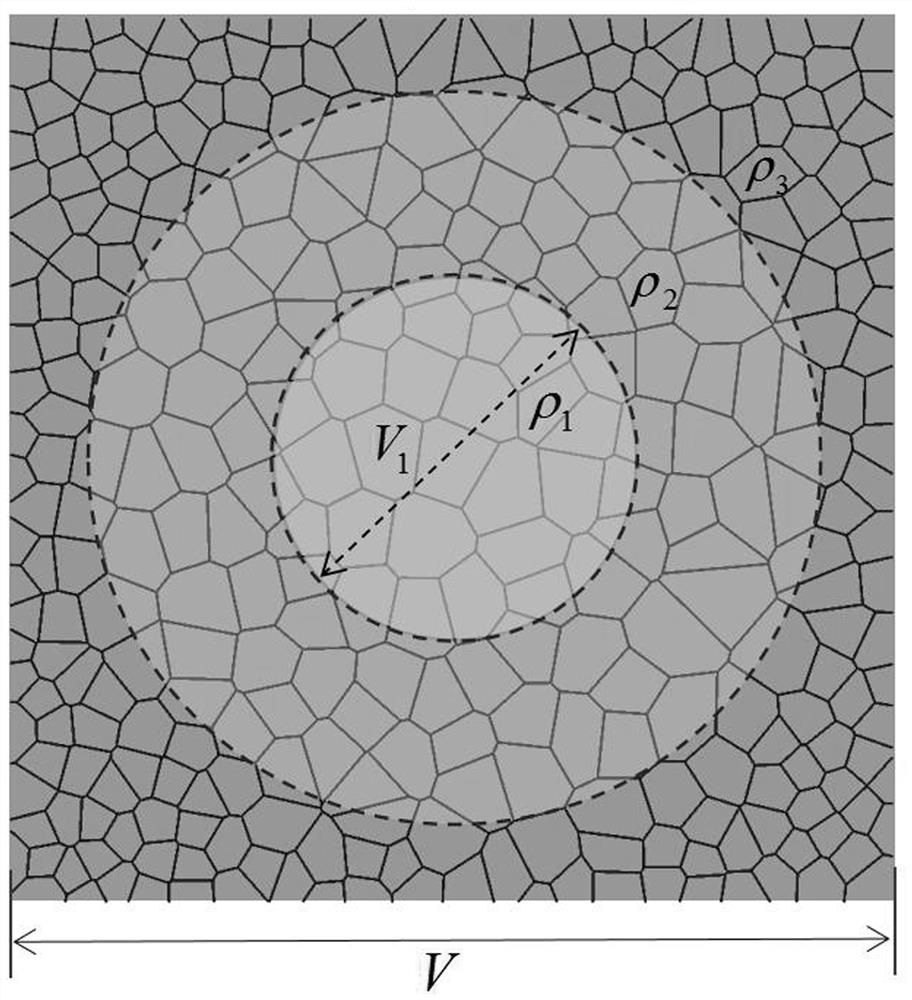

[0028] First, select closed-cell aluminum foams of different densities, and use a wire-cut electric discharge machine to cut the foam materials into cylindrical, circular, and other shapes of the same volume, and splicing and combining them according to the density. Taking the density change area divided into three layers as an example, the central layer is in the shape of a cylinder with a density of ρ 1 ; The middle layer is in the shape of a ring with a density of ρ 2 ;The outermost layer is a cube or cuboid after removing the cylinder inside, and the density is ρ 3 ,but ρ 1 ρ 2 ρ 3 ; According to the order of density and shape, weld or bond to obtain the radial gradient aluminum foam unit cell 3 . The porosity of the radial gradient aluminum foam unit cell gradually changes from the inside to the outside along the radial direction, from 90% to 50%.

[0029]Then, a certain number of radially negative gradient aluminum foam cells 3 are arranged sequentially in the p...

Embodiment 2

[0031] Example 2: First, using the method for preparing gradient porous materials in Chinese patent CN 101418391 B, the matrix powder is mixed with a porogen, and then absolute ethanol is added to prepare a suspension; then the suspension is poured into a mold, and then Centrifugal deposition; drying after centrifugal deposition, taking out the rough after demoulding, and then sintering in a graphite mold to obtain a billet; removing the porogen in the billet to obtain a radial negative gradient aluminum foam unit cell 3. The porosity of the radially gradient aluminum foam density gradually changes from the inside to the outside along the radial direction, from 80% to 10%, and the pore size is 30-480µm;

[0032] Then, a certain number of radially negative gradient aluminum foam cells 3 are arranged sequentially in the plane, and the surface contact parts between the cells are welded to obtain the radial gradient aluminum foam core layer 2 .

[0033] Finally, use sandpaper to p...

Embodiment 3

[0034] Example 3: First, select closed-cell aluminum foams of different densities, and use a wire-cut electric discharge machine to cut the foam materials into shapes such as cylinders and rings of the same volume, and splice and combine them according to the density. Taking the density change area divided into three layers as an example, the central layer is in the shape of a cylinder with a density of ρ 1 ; The middle layer is in the shape of a ring with a density of ρ 2 ;The outermost layer is a cube or cuboid after removing the cylinder inside, and the density is ρ 3 ,but ρ 1 ρ 2 ρ 3 ; According to the order of density and shape, weld or bond to obtain the radial gradient aluminum foam unit cell 3 . The density of the radial gradient aluminum foam is that the porosity gradually changes from the inside to the outside along the radial direction, from 90% to 50%.

[0035] Then, a certain number of radial negative gradient aluminum foam cells 3 are arranged sequential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com