Degradable packaging bag for express service

A packaging bag and polypropylene technology, applied in the field of express packaging bags, can solve the problems of unrecoverable land, environmental hazards, and non-separation, and achieve the effects of accelerating the degradation speed, increasing the degradation speed, and shortening the total length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

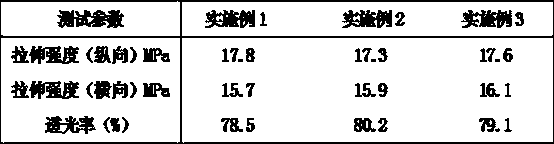

Embodiment 1

[0018] A degradable express packaging bag, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 50 parts of polypropylene alcohol, 10 parts of polylactic acid, 10 parts of chitin, 8 parts of propyl acetate, 5 parts of sodium hydroxide, permanganate Potassium 5 parts, corn starch 30 parts, cellulose 15 parts, calcium carbonate 15 parts, old paper powder 30 parts, iron acetonate 5 parts, inorganic pigment 5 parts, plasticizer 10 parts, coupling agent 5 parts.

[0019] Obtained from old paper powder passing through 80 meshes. The inorganic pigment is iron oxide; the plasticizer is phthalate, and the phthalate can be bis(2-ethylhexyl) phthalate (DEHP), dimethyl phthalate ( One of DMP), dibutyl phthalate (DBP), butyl benzyl phthalate (BBP), dioctyl phthalate (DOP); the coupling agent is a silane coupling agent , specifically one or more of KH550, KH560, KH570, KH792, DL602, DL171.

[0020] A preparation method of a degradable express packaging ba...

Embodiment 2

[0026] A degradable express packaging bag, comprising the following raw materials in parts by weight: 80 parts of polypropylene, 30 parts of polypropylene alcohol, 5 parts of polylactic acid, 5 parts of chitin, 5 parts of propyl acetate, 3 parts of sodium hydroxide, permanganate 3 parts of potassium, 20 parts of corn starch, 10 parts of cellulose, 10 parts of calcium carbonate, 20 parts of old paper powder, 3 parts of iron acetonate, 3 parts of inorganic pigment, 5 parts of plasticizer, and 2 parts of coupling agent.

[0027] Obtained from old paper powder passing through 60 mesh. The inorganic pigment is titanium oxide; the plasticizer is glycerin and propylene glycol; the titanate coupling agent is talcum powder and aluminum silicate.

[0028] The preparation method of a degradable courier packaging bag is the same as in Example 1, only the temperature for melting under inert gas is 170°C, and the temperature of the film blowing machine is set at 130°C.

Embodiment 3

[0030] A degradable express packaging bag, comprising the following raw materials in parts by weight: 90 parts of polypropylene, 40 parts of polypropylene alcohol, 8 parts of polylactic acid, 8 parts of chitin, 6 parts of propyl acetate, 4 parts of sodium hydroxide, permanganate Potassium 4 parts, corn starch 25 parts, cellulose 12 parts, calcium carbonate 12 parts, old paper powder 25 parts, iron acetonate 4 parts, inorganic pigment 4 parts, plasticizer 7 parts, coupling agent 4 parts.

[0031] Obtained from old paper powder passing through 70 meshes. The inorganic pigment is a mixture of iron oxide and titanium oxide; the plasticizer is glycerin; the titanate coupling agent is silicon dioxide.

[0032] The preparation method of a degradable express packaging bag is the same as that in Example 1, only the temperature for melting under inert gas is 160°C, and the temperature of the film blowing machine is set at 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com