Button cell pin and welding method thereof

A button battery and pin technology, which is applied to battery pack components, battery boxes/jackets, small-sized batteries/battery packs, etc., can solve the problem of unprofessional processing of button batteries, inconvenient use, flexibility, and not easy to weld firmly. and other problems, to achieve the effect of improving anti-oxidation performance, improving just oxidation ability, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

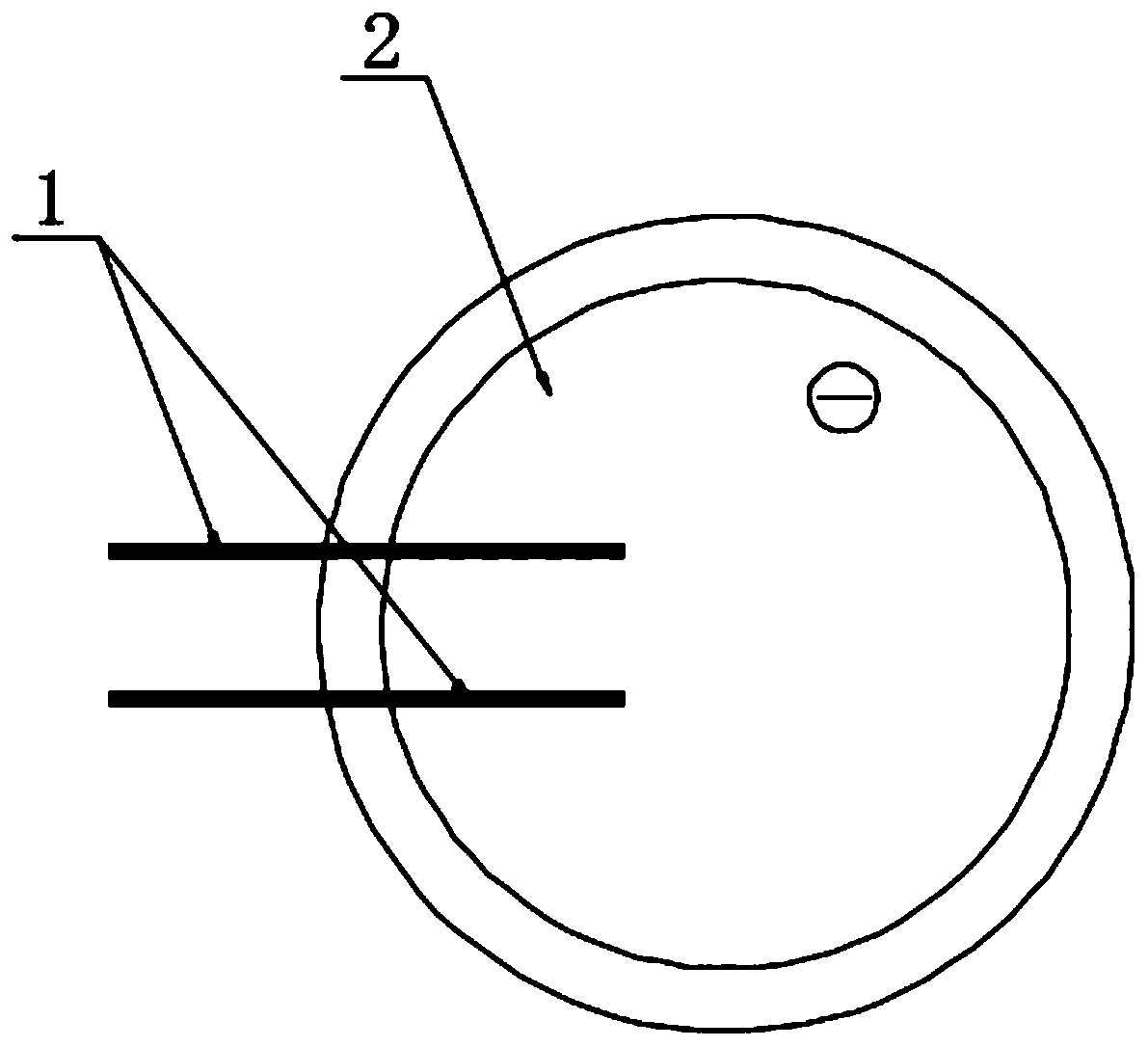

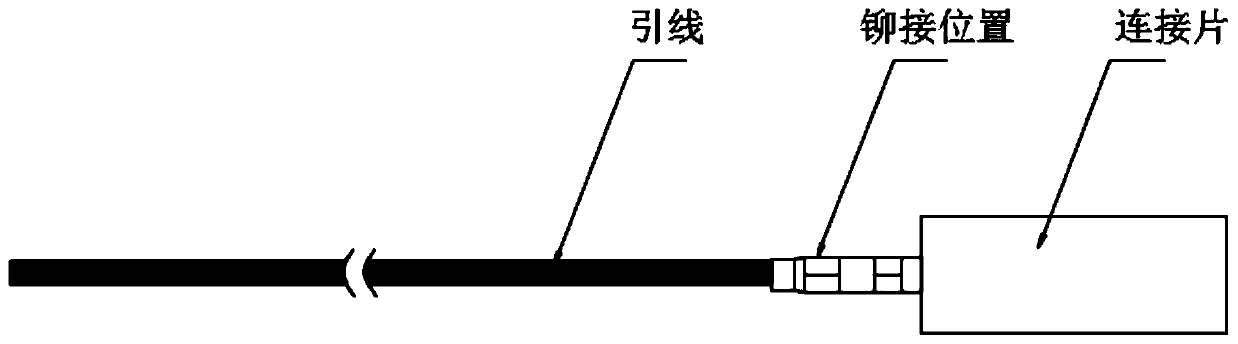

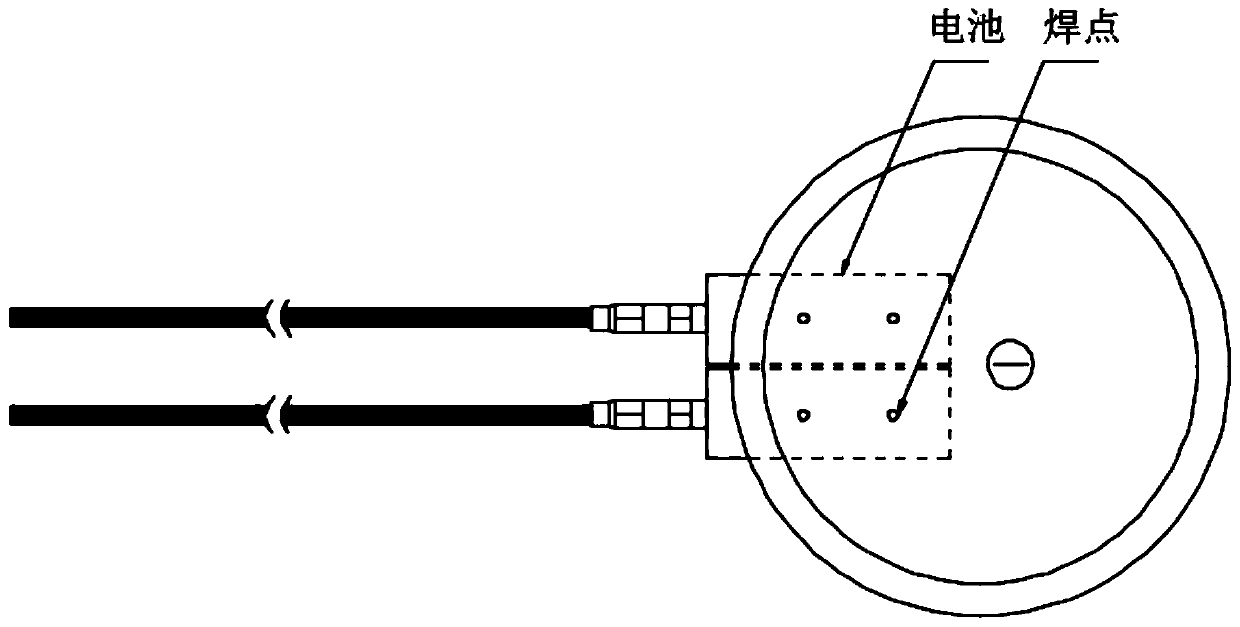

[0036] Refer to the attached figure 1 , a button battery pin of this embodiment, the pin includes a wire 1, the wire 1 is specifically a single core wire, and the wire 1 is made of a single metal or alloy material whose melting point is close to the melting point of the battery steel case 2 The wire 1 is welded and connected to the steel case 2 of the battery through welding pins.

[0037] The button battery can be a primary AG zinc-manganese battery, a CR lithium-manganese battery or a secondary LIR lithium-ion rechargeable battery, etc., without limitation.

[0038] Further, the single metal making the wire 1 is specifically nickel.

[0039] Further, the surface of the wire 1 is coated with an insulating layer, and the insulating layer is specifically an insulating environmental protection glue.

[0040] The present invention also provides a method for processing button battery pins, comprising the following processing steps:

[0041] S1. Put the raw material of the wire...

Embodiment 2

[0049] Refer to the attached figure 1 , a button battery pin of this embodiment, the pin includes a wire 1, the wire 1 is specifically a single core wire, and the wire 1 is made of a single metal or alloy material whose melting point is close to the melting point of the battery steel case 2 Made, the wire 1 is welded and connected to the battery steel case 2 through welding pins;

[0050] Further, the alloy material for making the wire 1 is composed of the following raw materials in terms of weight percentage: 70wt% nickel, 15wt% aluminum, 5wt% silicon, 5wt% molybdenum, 2wt% metal rare earth elements, 2wt% zirconium, modified carbon 0.5 wt% of nanotubes and 0.5 wt% of nano boron fibers, the modified carbon nanotubes are specifically 0.7nm carbon nanotubes.

[0051] Further, the metal rare earth element is specifically yttrium.

[0052] Further, the surface of the wire 1 is coated with an insulating layer, and the insulating layer is specifically an insulating environmental ...

Embodiment 3

[0062] Refer to the attached figure 1 , a button battery pin of this embodiment, the pin includes a wire 1, the wire 1 is specifically a single core wire, and the wire 1 is made of a single metal or alloy material whose melting point is close to the melting point of the battery steel case 2 Made, the wire 1 is welded and connected to the battery steel case 2 through welding pins;

[0063] Further, the alloy material for making the wire 1 is composed of the following raw materials by weight percentage: 75wt% nickel, 12wt% aluminum, 5wt% silicon, 5wt% molybdenum, 1wt% metal rare earth element, 1wt% zirconium, modified carbon 0.5 wt% of nanotubes and 0.5 wt% of nano boron fibers, the modified carbon nanotubes are specifically 0.7nm carbon nanotubes.

[0064] Further, the metal rare earth element is specifically yttrium.

[0065] Further, the surface of the wire 1 is coated with an insulating layer, and the insulating layer is specifically an insulating environmental protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com