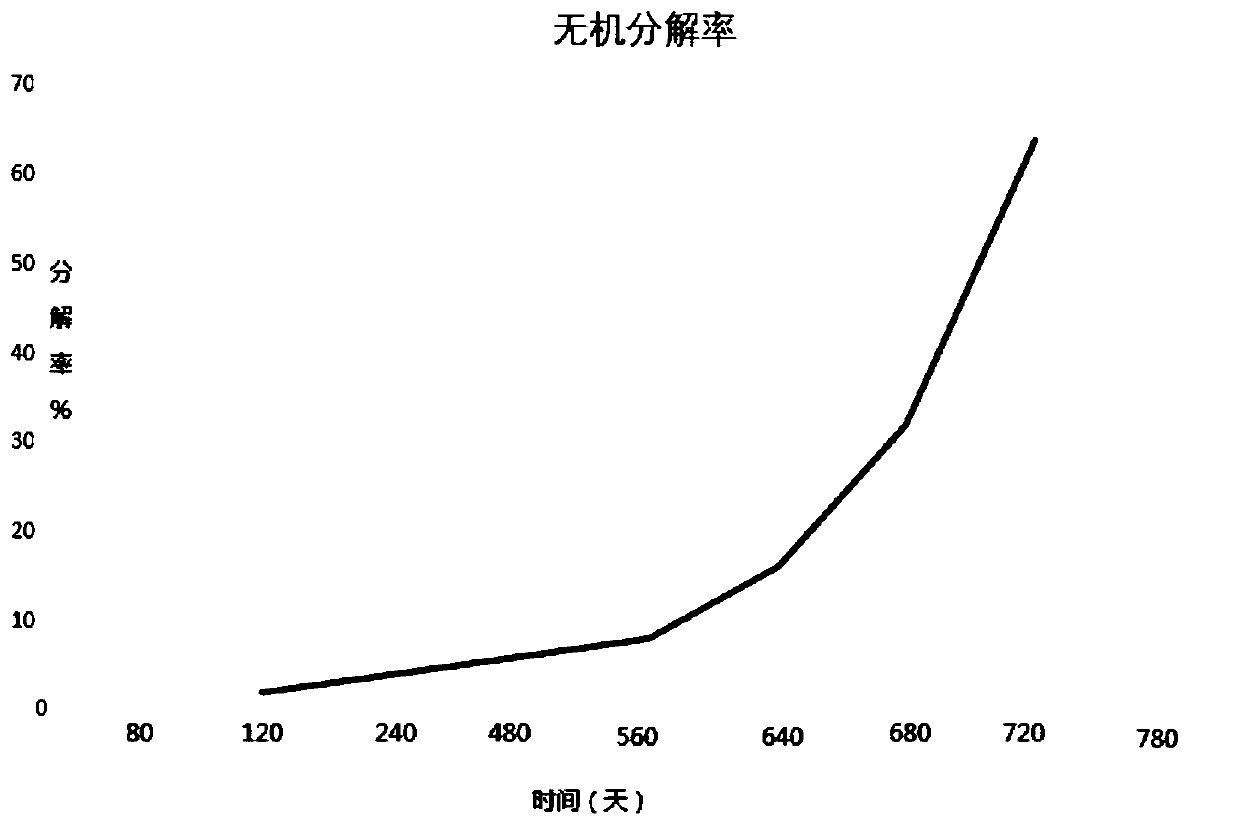

Pearl wool as well as preparation method and application thereof

A kind of pearl cotton, selected technology, applied in the direction of sustainable manufacturing/processing, flexible covering, biological packaging, etc., can solve the problems of poor anti-static and anti-rust performance, non-degradable pearl cotton, flame retardant and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

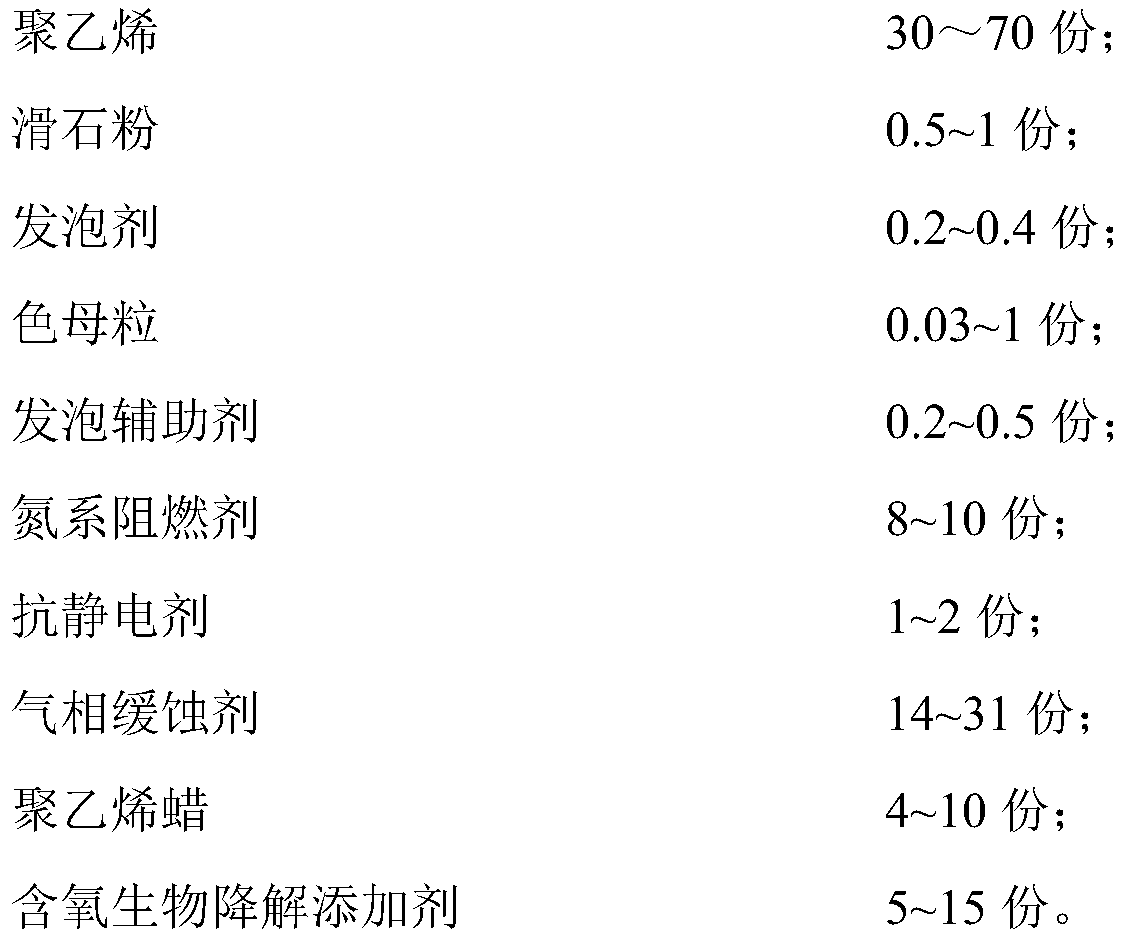

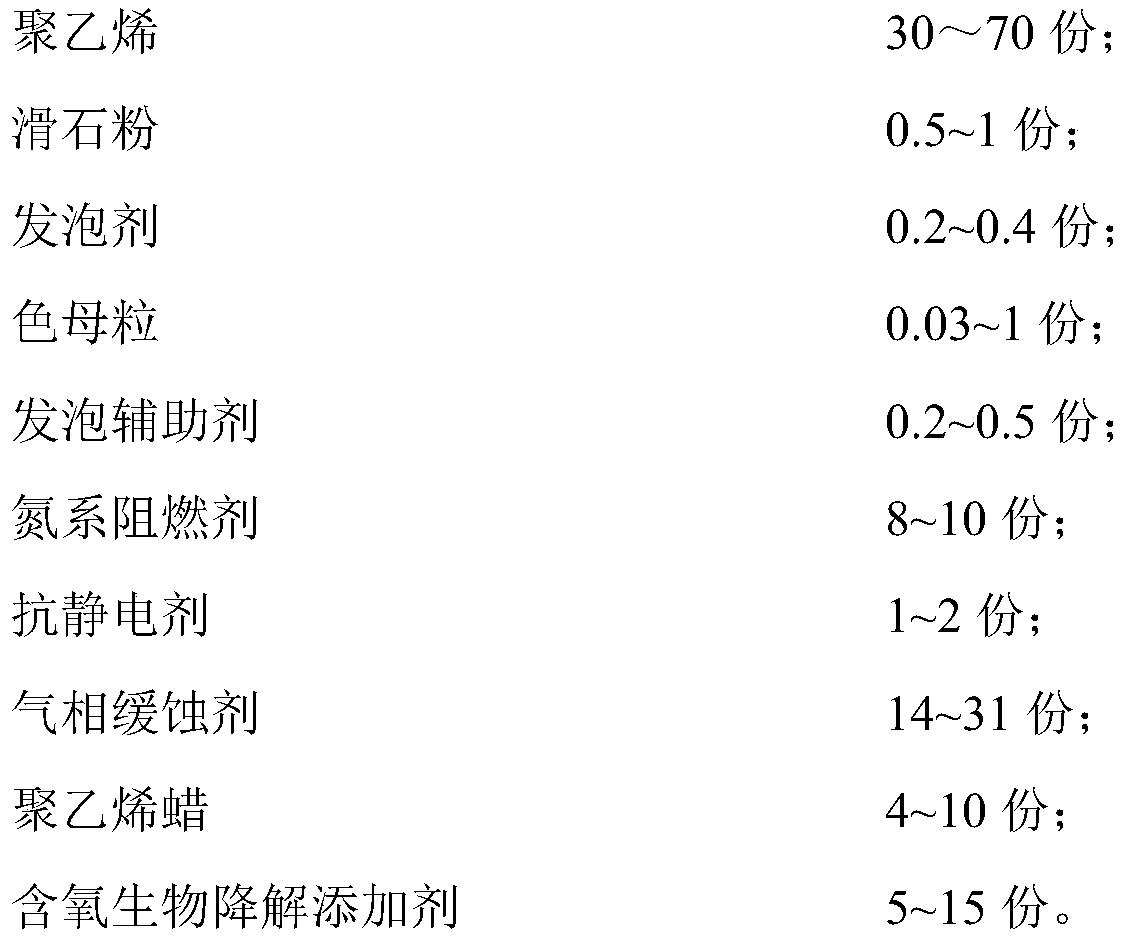

Method used

Image

Examples

preparation example Construction

[0044] In the preparation method of the pearl cotton provided by the present invention, specifically, the talc powder is pulverized, and the temperature is raised to 80-85°C under high-speed stirring, and then polyethylene, color masterbatch, nitrogen-based flame retardant, gas phase corrosion inhibitor, anti-corrosion Static agent, polyethylene wax, oxygen-containing biodegradable additive, the mixture is stirred at 100-120°C, and then the foaming agent and foaming auxiliary agent are respectively injected into it by high-pressure injection, mixed evenly, and extruded. Then cooling, traction, flattening, winding, obtained pearl cotton of the present invention.

[0045] The third aspect of the present invention provides the application of the pearl cotton provided by the first aspect of the present invention in the packaging field. The packaging field can specifically be in the field of metal rust-proof packaging.

[0046] Beneficial effects of the present invention:

[0047...

Embodiment 1

[0054] A degradable flame-retardant antistatic vapor phase antirust pearl cotton, including the following raw materials calculated in parts by weight: 68 parts of LDPE particles, 0.5 parts of talcum powder, 0.2 parts of foaming agent, 0.03 parts of color masterbatch, 0.2 parts of monoglyceride 7 parts, 7 parts of melamine polyphosphate, 1 part of antistatic agent, 5 parts of sodium benzoate, 3 parts of benzotriazole, 6 parts of 4-(N,N-di-n-butyl)-aminomethylmorpholine, 4 parts of polyethylene wax, 5 parts of oxygen-containing biodegradable additive.

[0055] Wherein the foaming agent is butane,

[0056] The color masterbatch is the xd series of Shanghai Xuande Plastic Co., Ltd.,

[0057] The antistatic agent is an ethoxylated alkylamine,

[0058] Oxygen-containing biodegradable additives are BD series produced by Wells plastic co.ltd in the UK.

[0059] The degradable flame retardant antistatic vapor phase antirust pearl cotton and its manufacturing method comprise the foll...

Embodiment 2

[0061] A pearl cotton, comprising the following raw materials calculated in parts by weight: 54 parts of LDPE particles, 0.8 parts of talcum powder, 0.3 parts of foaming agent, 0.04 parts of color masterbatch, 0.3 parts of monoglyceride, and 8 parts of melamine polyphosphate , 1 part of antistatic agent, 7 parts of sodium benzoate, 5 parts of benzotriazole, 9 parts of 4-(N,N-di-n-butyl)-aminomethylmorpholine, 8 parts of polyethylene wax, oxygen-containing biological 10 parts of degradation additives.

[0062] Wherein the blowing agent is pentane,

[0063] The color masterbatch is the xd series of Shanghai Xuande Plastic Co., Ltd.,

[0064] The antistatic agent is fatty acid polyol fat,

[0065] The oxygen-containing biodegradation additive is a biodegradation agent produced by Wanlerlambert Company of the United States.

[0066] The manufacturing method of the pearl cotton comprises the following steps: first, crush the talcum powder to 300 mesh, then put it into a mixer, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com