Injectable hydrogel with high mechanical strength and stability, and preparation method and application thereof

A technology of mechanical strength and stability, applied in the field of biomedical materials, can solve the problems of decreased mechanical properties, poor mechanical strength of injectable hydrogels, etc., to achieve excellent mechanical properties, good biocompatibility, and good long-term stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Refer to the patent No. 201810670921.7 for the synthesis of hydroxylamino-terminated polyethylene glycol block polymers. The synthesis steps are as follows:

[0051] 1.1 Add 1.5g of guanidine carbonate and 20mL of absolute ethanol to the flask, then add 2.2mL of α-acetyl-γ-butyrolactone and 5.5mL of triethylamine. The reaction was stirred and refluxed at 90° C. for 2 h, and then lowered to room temperature for more than 4 h. The white precipitate was collected, washed 2-3 times with ice ethanol (4° C.), and dried to obtain the first intermediate.

[0052]1.2 Add 1 g of the first intermediate to the flask, then add 20 mL of 1,6-hexamethylene diisocyanate and 1 mL of pyridine. Under the protection of nitrogen, the temperature was raised to 90° C. for 3 h until the solution became completely transparent. Then, the reaction liquid was directly precipitated in 400 mL of n-pentane, and the second intermediate was collected.

[0053] 1.3 Add 0.81 g of N, N'-carbonyldiimidaz...

Embodiment 2

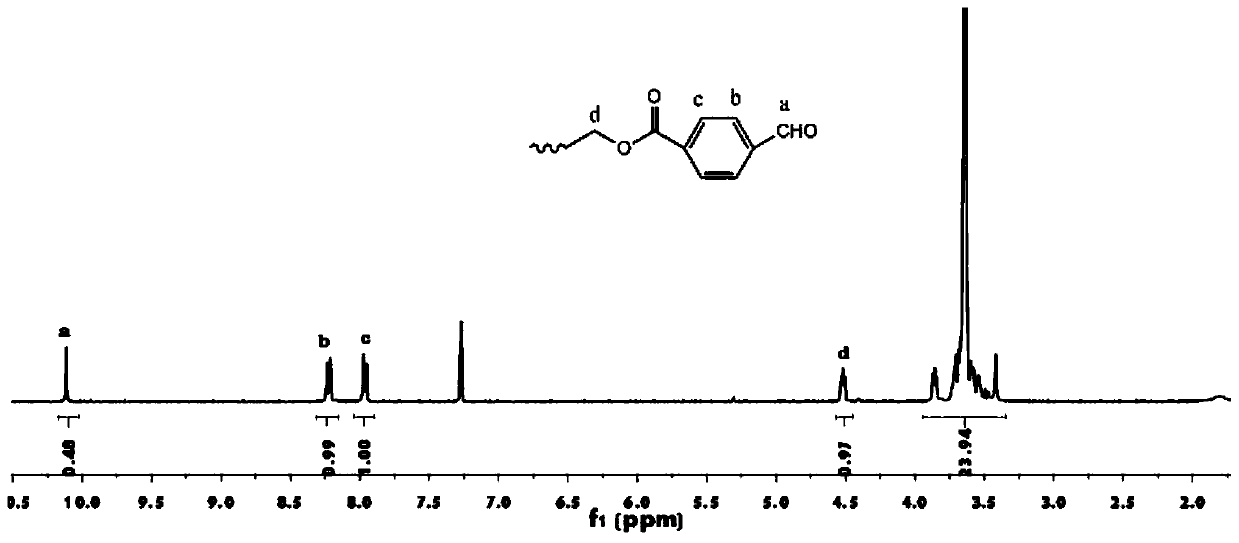

[0060] Synthetic steps of four-arm polyethylene glycol terminated by aldehyde group

[0061] Add 1 g of four-armed polyethylene glycol (molecular weight: 2000 Da), 0.6 g of p-carboxybenzaldehyde, 0.82 g of dicyclohexylcarbodiimide, 0.2 g of 4-dimethylaminopyridine, and 30 mL of tetrahydrofuran into the flask. Under nitrogen condition, react at 40°C for 36h. Afterwards, the reaction solution was filtered, spin-dried and then dissolved in CH 2 Cl 2 in, with 95% CH 2 Cl 2 / 5% MeOH was used as eluent, and the aldylated four-arm PEG2k was separated by silica gel chromatography. The aldehyde-terminated four-armed polyethylene glycol with the structure of formula ii is finally obtained. Such as figure 1 As shown, the nuclear magnetic spectrum proved the successful synthesis of the product. Its aldehyde group capping ratio is 98%, and the number average molecular weight is 2428-2628Da.

Embodiment 3

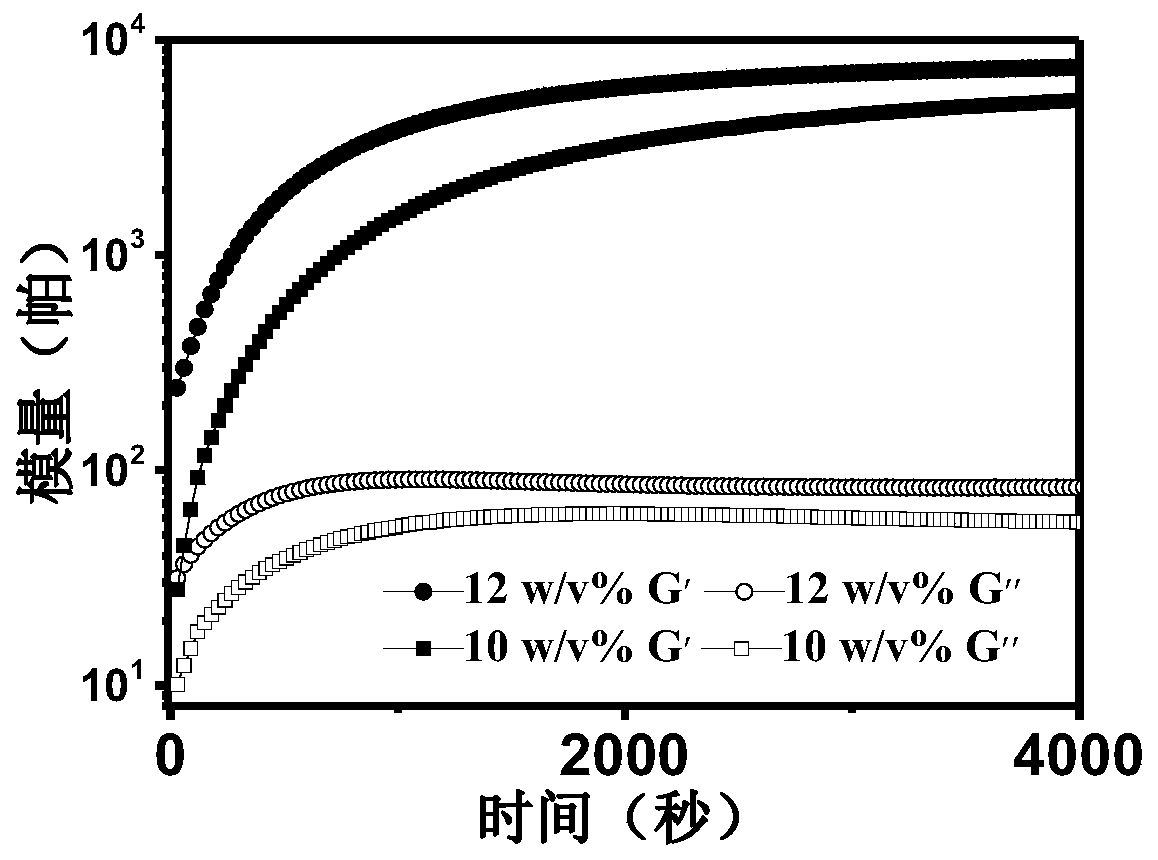

[0063] Preparation of hydrogel

[0064] The polyethylene glycol block polymer terminated by the hydroxyl amino group with the structure of formula i was dissolved in phosphate buffer (0.0125M, pH=5.2), and prepared into solutions with concentrations of 11.1w / v% and 13.3w / v% respectively , is the first mixed solution. Heat the solution in a water bath at 70°C for 15-20 minutes until the polymer is completely dissolved and a uniform transparent liquid is formed.

[0065] The four-armed polyethylene glycol terminated with aldehyde group having the structure of formula ii was dissolved in phosphate buffer (0.0125M, pH=5.2), and prepared into solutions with concentrations of 6.8w / v% and 8.2w / v%, respectively, as Second mixture.

[0066] Fully mix 750 μL of the 11.1w / v% first mixed solution and 250 μL of the 6.8w / v% second mixed solution at 37°C, and let it stand at 37°C for more than 12 hours to ensure complete gelation and obtain a solute concentration of 10w / v %.

[0067] Ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com