Method for directly preparing Sb4O5Cl2 from Sb2O3 and hydrochloric acid aqueous solution

A hydrochloric acid aqueous solution, sb2o3 technology, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve the problems of high reaction temperature, inconvenient use, high concentration of hydrochloric acid, and achieve mild production process conditions, easy to control, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In order to further illustrate the content of the present invention, the present invention is further described in the following examples.

[0070] In this example, exemplification according to the present invention was carried out in a 2000 ml glass beaker with a mechanical stirring paddle in a constant temperature water bath. The hydrochloric acid adopts industrial hydrochloric acid (37.5%), and the water adopts domestic drinking water. Prepare 1000 ml of an aqueous solution containing 0.6 mol / l hydrochloric acid. Heating to 30°C, under stirring, 111 g of Sb 2 o 3 (purity > 99.00%) added to the liquid, Sb 2 o 3 After the addition, keep the temperature at 30°C and stir the reaction for 1 hour to complete the Sb 4 o 5 Cl 2Crystal preparation reactions. After the reaction, the obtained slurry was filtered. Sb 4 o 5 Cl 2 Crystalline product The product was washed with 30 ml of water. Then dry to constant weight in a vacuum oven with a water extraction system....

Embodiment 2

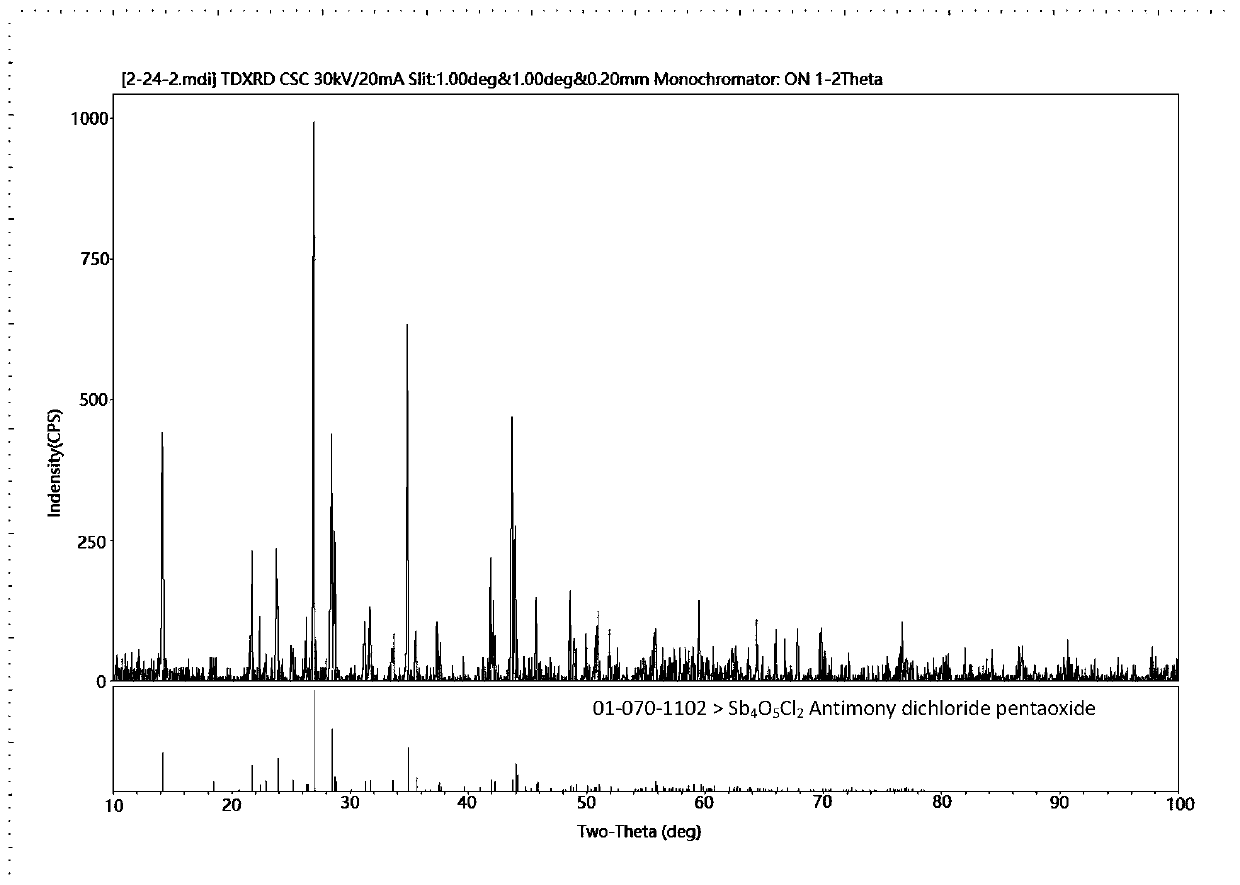

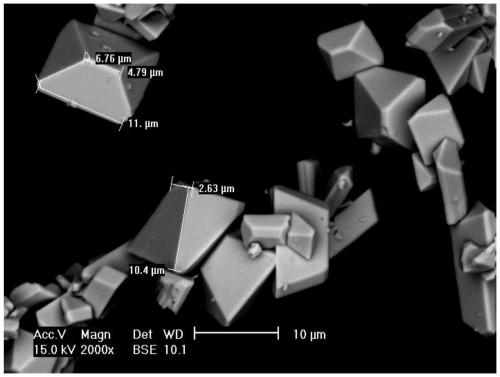

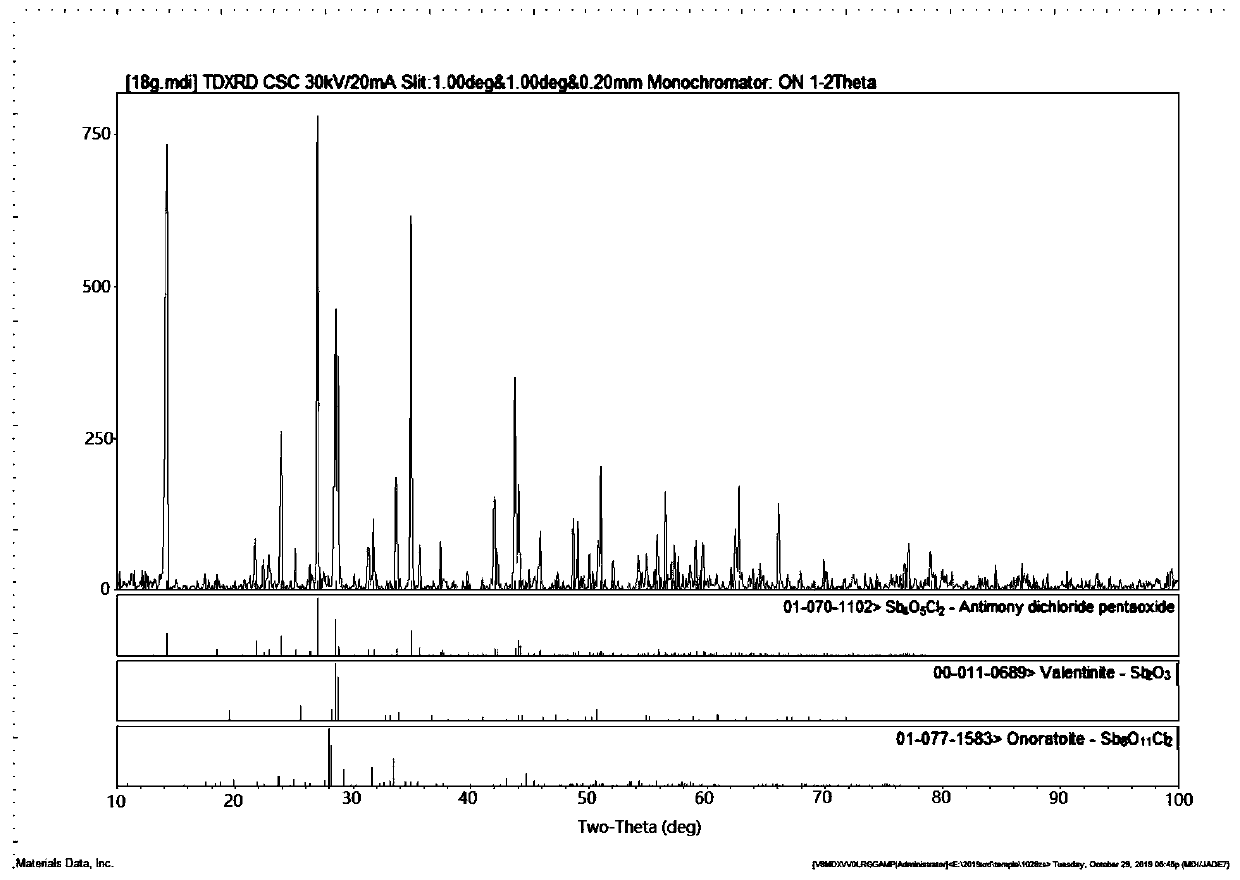

[0073] In this example, exemplification according to the present invention was carried out in a 2000 ml glass beaker with a mechanical stirring paddle in a constant temperature water bath. First prepare 1000 milliliters of an aqueous solution containing 0.45 mol / l hydrochloric acid, the reagent is analytically pure hydrochloric acid, and the water is distilled water. This solution was heated to 55°C, and 90 g of Sb 2 o 3 (purity > 99.00%) added to the liquid, Sb 2 o 3 After the addition, keep the temperature at 55°C and stir the reaction for 40 minutes to complete the Sb 4 o 5 Cl 2 Crystal preparation reactions. After the reaction, the slurry was filtered. Sb 4 o 5 Cl 2 Crystalline product The product was washed with 30 ml of water. Then dry to constant weight in a vacuum oven with a water extraction system. Yield 106.4 g Sb 4 o 5 Cl 2 crystals. The crystal contains 76.34% of antimony (76.35% in theory) and 11.12% of chlorine (11.11% in theory). X-ray diffract...

Embodiment 3

[0075] In this example, examples according to the present invention were carried out in a 2000 ml plastic beaker with a mechanical stirring paddle and a constant temperature water bath. The hydrochloric acid adopts industrial hydrochloric acid (37.5%), and the water adopts domestic drinking water. First prepare 1000 milliliters of an aqueous solution containing 0.76 mol / l hydrochloric acid. This solution was heated to 40°C, and 120 g of Sb 2 o 3 (purity > 99.00%) added to the liquid, Sb 2 o 3 After the addition, keep the temperature at 40°C and stir the reaction for 1 hour to complete the Sb 4 o 5 Cl 2 Crystal preparation reactions. After the reaction, the slurry was filtered. Sb 4 o 5 Cl 2 Crystalline product The product was washed with 30 ml of water. Then dry to constant weight in a vacuum oven with a water extraction system. Yield 130.1 g Sb 4 o 5 Cl 2 crystals. The crystal contains 76.31% of antimony (76.35% in theory) and 11.22% of chlorine (11.11% in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com