Vinyl chloride copolymer emulsion for water-based anticorrosive coating as well as preparation method and application thereof

A vinyl chloride copolymerization and anti-corrosion coating technology, applied in the field of chemical engineering, can solve the problems of increased film-forming temperature of copolymer emulsion, decreased anti-corrosion performance, complicated preparation process, etc. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

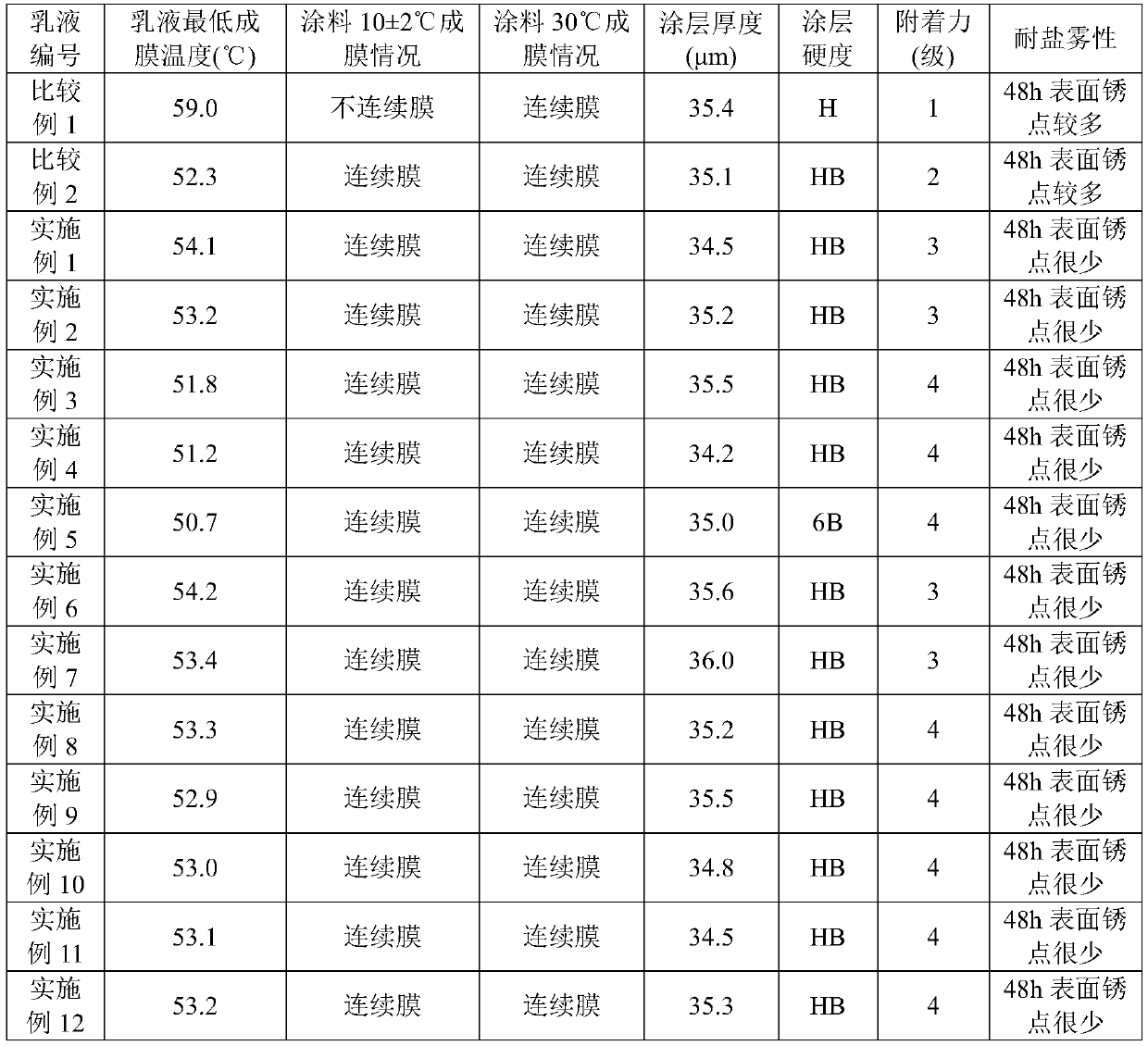

Examples

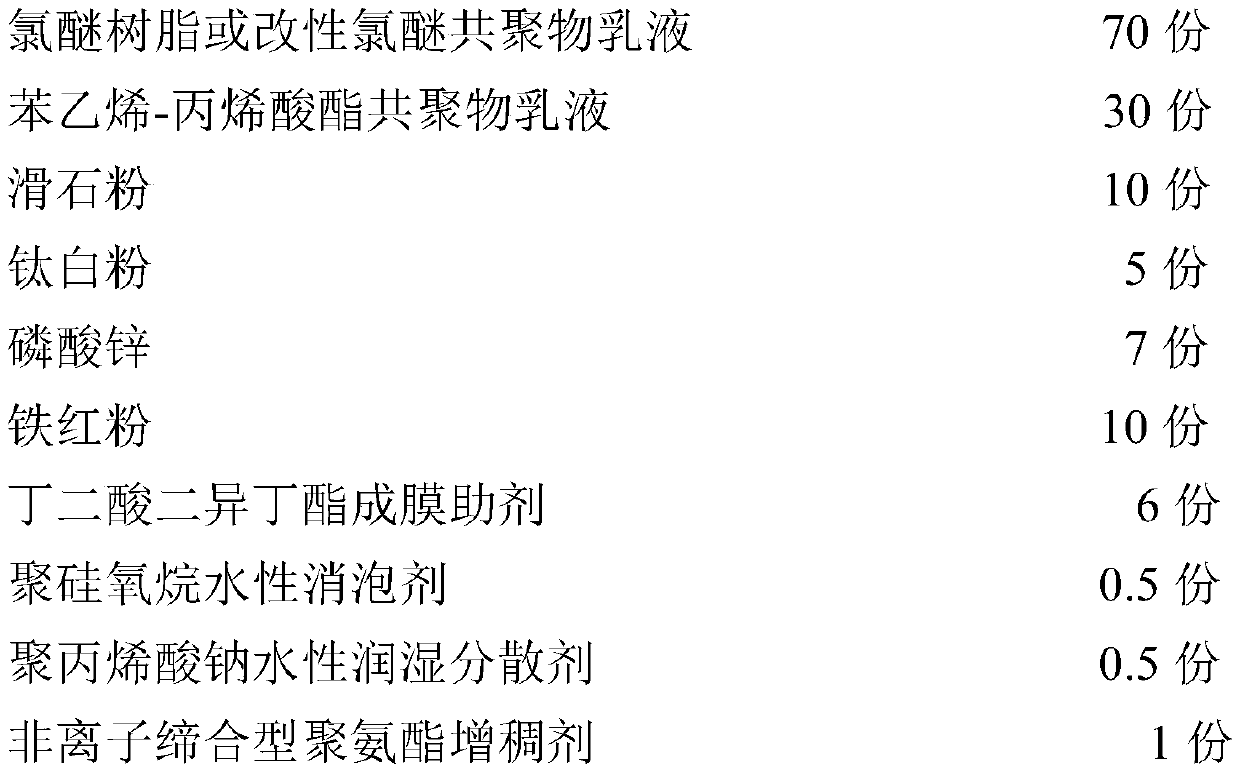

Embodiment 1

[0022] Add 150g deionized water, 35g vinyl chloride, 25g chloropropene and isobutyl vinyl ether (the mass ratio of chloropropene and isobutyl vinyl ether is 1:1), 2g maleic anhydride, 2.5 g sodium lauryl sulfate and 0.5 g α-propenyl alkylphenol polyoxyethylene ether ammonium sulfate compound emulsifier, 0.2 g sodium bisulfite reducing agent, heat up to 55 ° C, drop at a rate of 2.0 g / hour Add 5% ammonium persulfate aqueous solution to start the polymerization, and continuously add 38g of vinyl chloride monomer to keep the pressure of the polymerization system basically unchanged. After the addition of vinyl chloride is completed, continue the reaction until the system pressure drops by 1.0kg / cm 2 , the polymerization was completed by cooling, and the unreacted vinyl chloride, propylene chloride and isobutyl vinyl ether were removed to obtain a modified chloroether copolymer emulsion with a solid content of 35.6%.

Embodiment 2

[0024] Add 150g deionized water, 35g vinyl chloride, 25g chloropropene and isobutyl vinyl ether (mass ratio of chloropropene and isobutyl vinyl ether is 1:1.5), 2g maleic anhydride, 2.5 g sodium lauryl sulfate and 0.5 g of α-propenyl alkylphenol polyoxyethylene ether ammonium sulfate compound emulsifier, 0.2 g of sodium bisulfite reducing agent, warming up to 55 ° C, dripping at a rate of 2.0 g / h Add 5% ammonium persulfate aqueous solution to start polymerization, and continuously add 38g of vinyl chloride monomer to keep the pressure of the polymerization system basically unchanged. After the addition of vinyl chloride is completed, continue to react until the system pressure drops by 1.0kg / cm 2 , the polymerization was completed by cooling, and the unreacted vinyl chloride, chloropropene and isobutyl vinyl ether were removed to obtain a modified chloroether copolymer emulsion with a solid content of 35.8%.

Embodiment 3

[0026]Add 150g deionized water, 35g vinyl chloride, 25g chloropropene and isobutyl vinyl ether (mass ratio of chloropropene and isobutyl vinyl ether is 1:2), 2g maleic anhydride, 2.5 g sodium lauryl sulfate and 0.5 g of α-propenyl alkylphenol polyoxyethylene ether ammonium sulfate compound emulsifier, 0.2 g of sodium bisulfite reducing agent, warming up to 55 ° C, dripping at a rate of 2.0 g / h Add 5% aqueous solution of ammonium persulfate to start polymerization, and continuously add 38g of vinyl chloride monomer to keep the pressure of the polymerization system basically unchanged. After adding vinyl chloride, continue to react until the system pressure drops by 1.0kg / cm 2 , the polymerization was completed by cooling, and the unreacted vinyl chloride, propylene chloride and isobutyl vinyl ether were removed to obtain a modified chloroether copolymer emulsion with a solid content of 36.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com