Preparation method of reactive acrylate crosslinking agent

A technology of acrylates and crosslinking agents, which is applied in the field of preparation of reactive acrylates crosslinking agents, can solve problems such as high acid value and high viscosity, and achieve the effects of high product purity, convenient operation and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

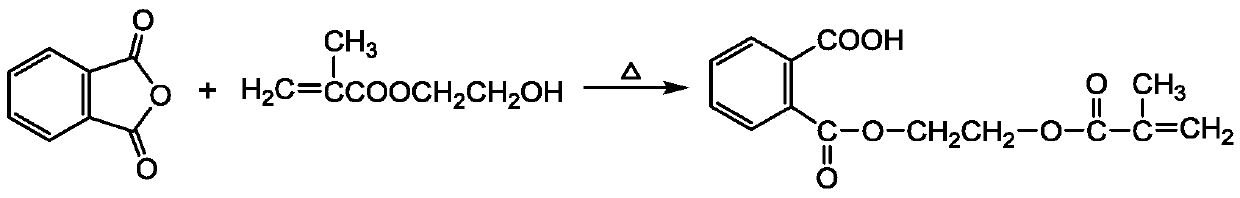

[0020] A preparation method of reactive acrylate crosslinking agent, comprising the following steps:

[0021] S1: Put phthalic anhydride compounds and acrylate compounds into a reaction vessel with mechanical stirring, the molar ratio of the two is 1:1-1.5, in order to inhibit the polymerization of acrylate compounds, it is necessary to add the first polymerization inhibitor, which The mass percentage of the total mass of the reaction raw materials (namely acid anhydride and acrylate compound) is 0.01-0.5%. After the three are mixed, the reaction is carried out at a temperature of 80-120° C. for 4-12 hours to obtain an intermediate product.

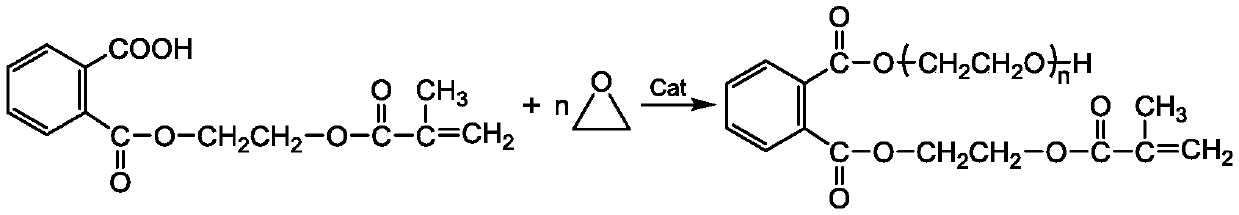

[0022] S2: Add the second polymerization inhibitor and catalyzer in described reaction vessel, the mol ratio of described intermediate product and epoxy monomer is 1:1-10, and the quality of described second polymerization inhibitor accounts for reaction raw material ( That is, the percentage of the total mass of the intermediate product ...

Embodiment 1

[0032] A preparation method of reactive acrylate crosslinking agent, comprising the following steps:

[0033] S1: Put 296g of phthalic anhydride, 232g of hydroxyethyl acrylate, and 0.1g of the first polymerization inhibitor hydroquinone into a three-necked round-bottomed flask with mechanical stirring, start stirring, and heat up to 80°C. Stir for 12h to obtain about 524g of intermediate product;

[0034] S2: Take 264g of the intermediate and put it into the glass reactor, then put in 0.06g of the catalyst triethylamine and 0.06g of the second polymerization inhibitor hydroquinone, start stirring; raise the temperature of the glass reactor to 30°C, and start slowly dripping Add 44g of ethylene oxide, and keep the reaction temperature at 30-35°C in order to prevent the polymerization reaction of the raw materials at too high a temperature; after the ethylene oxide is added dropwise, continue to keep warm for 1 hour; then vacuumize until the glass reactor is vacuumed The temper...

Embodiment 2

[0036] A preparation method of reactive acrylate crosslinking agent, comprising the following steps:

[0037] S1: Put 296g of phthalic anhydride and 260g of hydroxypropyl acrylate into a three-neck round bottom flask with mechanical stirring, add 2.8g of the first polymerization inhibitor hydroquinone, start stirring, raise the temperature to 100°C, and stir 6h, obtain intermediate product 556g;

[0038] S2: Take 278g of the intermediate and put it into a 2.5L glass reactor, then put in 7.2g of the catalyst triethylenediamine and 3.6g of the second polymerization inhibitor p-hydroxyanisole, start stirring; raise the temperature of the glass reactor to 50 ℃, began to slowly drop 440g of ethylene oxide, in order to prevent the polymerization reaction of raw materials from excessive temperature, the reaction temperature was kept at 50-55 ℃; after the ethylene oxide was added dropwise, continue to keep warm for 5h; Then vacuumize until the vacuum degree in the glass reactor is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com