Method for producing high-energy hydrocarbon fuel through anthracene oil treatment

A technology of hydrocarbon fuel and anthracene oil, which is applied in the field of coal chemical industry, can solve the problems of difficult to meet the requirements of aerospace vehicles and high freezing point, and achieve the effect of increasing utilization value, increasing volume calorific value, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

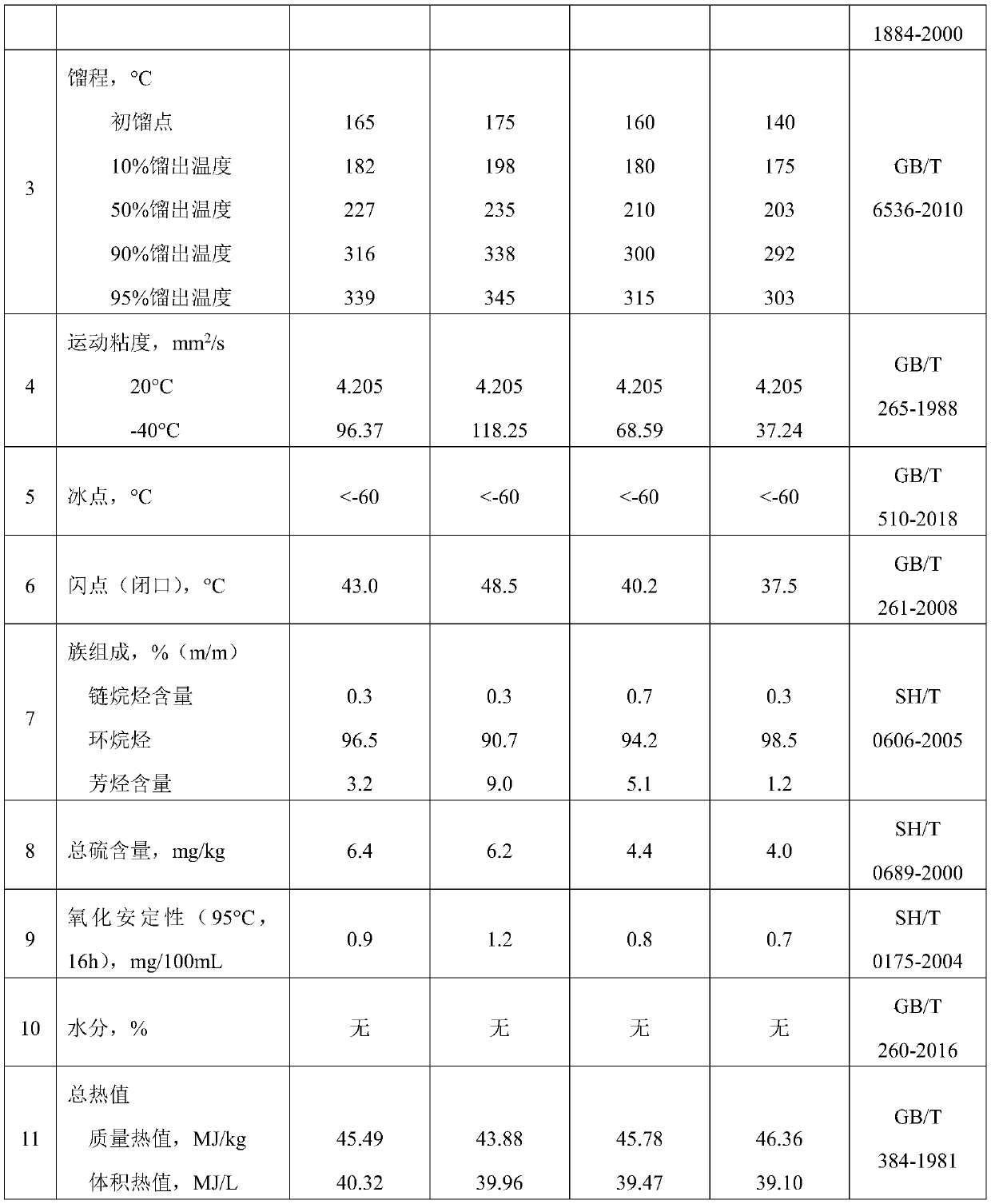

Embodiment 1

[0024] The anthracene oil raw material is preheated and mixed with hydrogen into the first-stage hydrogenation reactor. The catalyst used is prepared with reference to the existing commercial hydrorefining catalyst, wherein molybdenum trioxide contains 17wt%, tungsten trioxide contains 11wt%, oxidation Nickel contains 3wt%, the rest is alumina carrier, the specific surface area is 160m 2 / g, the total pore volume is 0.7mL / g. The reaction conditions are: reaction temperature 380°C, reaction pressure 15MPa, hydrogen to oil volume ratio 1600:1, liquid hourly volume space velocity 0.3h -1 . The purpose of this refining stage is to carry out hydrodesulfurization, denitrogenation, and deoxygenation treatment on anthracene oil, and at the same time, part of the aromatics are saturated. After the resulting refined product is separated from gas and liquid by a high-pressure separator, the hydrogen-rich gas circulates and enters the reactor, and the obtained oil phase product enters t...

Embodiment 2

[0026] The first-stage refined product enters the second-stage hydrogenation reactor, and the catalyst used is prepared with reference to the existing commercial hydrocracking catalyst, wherein molybdenum trioxide contains 26wt%, nickel oxide contains 5wt%, silicon dioxide contains 30wt%, alumina Containing 39wt%, the specific surface area is 200m 2 / g, the total pore volume is 0.4mL / g. The reaction conditions are: reaction temperature 390°C, reaction pressure 15MPa, hydrogen to oil volume ratio 1600:1, liquid hourly volume space velocity 0.3h -1 . The purpose of this refining stage is to carry out deep aromatics saturation and ring-opening cracking treatment on the refined anthracene oil, so as to improve the low-temperature performance of the product and increase the calorific value. After the resulting refined product is separated from gas and liquid by a high-pressure separator, the hydrogen-rich gas circulates and enters the reactor, and the resulting oil-phase product ...

Embodiment 3

[0028] The second-stage refined product enters the third-stage hydrogenation reactor, and the catalyst used is a self-made noble metal / molecular sieve / alumina composite catalyst, in which platinum contains 0.5wt%, silica contains 8.8wt%, and alumina contains 90.7wt% , the specific surface area is 220m 2 / g, the total pore volume is 0.65mL / g. The reaction conditions are: reaction temperature 250°C, reaction pressure 4MPa, hydrogen to oil volume ratio 600:1, liquid hourly volume space velocity 0.6h -1 . The purpose of this refining stage is to further saturate the refined product with aromatics, so as to improve the stability of the product and further increase the calorific value. After the resulting refined product is separated from gas and liquid by a high-pressure separator, the hydrogen-rich gas circulates and enters the reactor, and the obtained oil phase product is tested as the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com