Three-dimensional inorganic polymer composite solid electrolyte and ternary solid-state lithium battery

A solid electrolyte and inorganic polymer technology, applied in solid electrolyte, non-aqueous electrolyte battery, lithium battery, etc., can solve the problems of poor long-term cycle performance of batteries, mechanical properties of composite solid electrolytes that need to be further improved, and short cycle life. Achieve the effects of improving cycle stability, low cost, and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

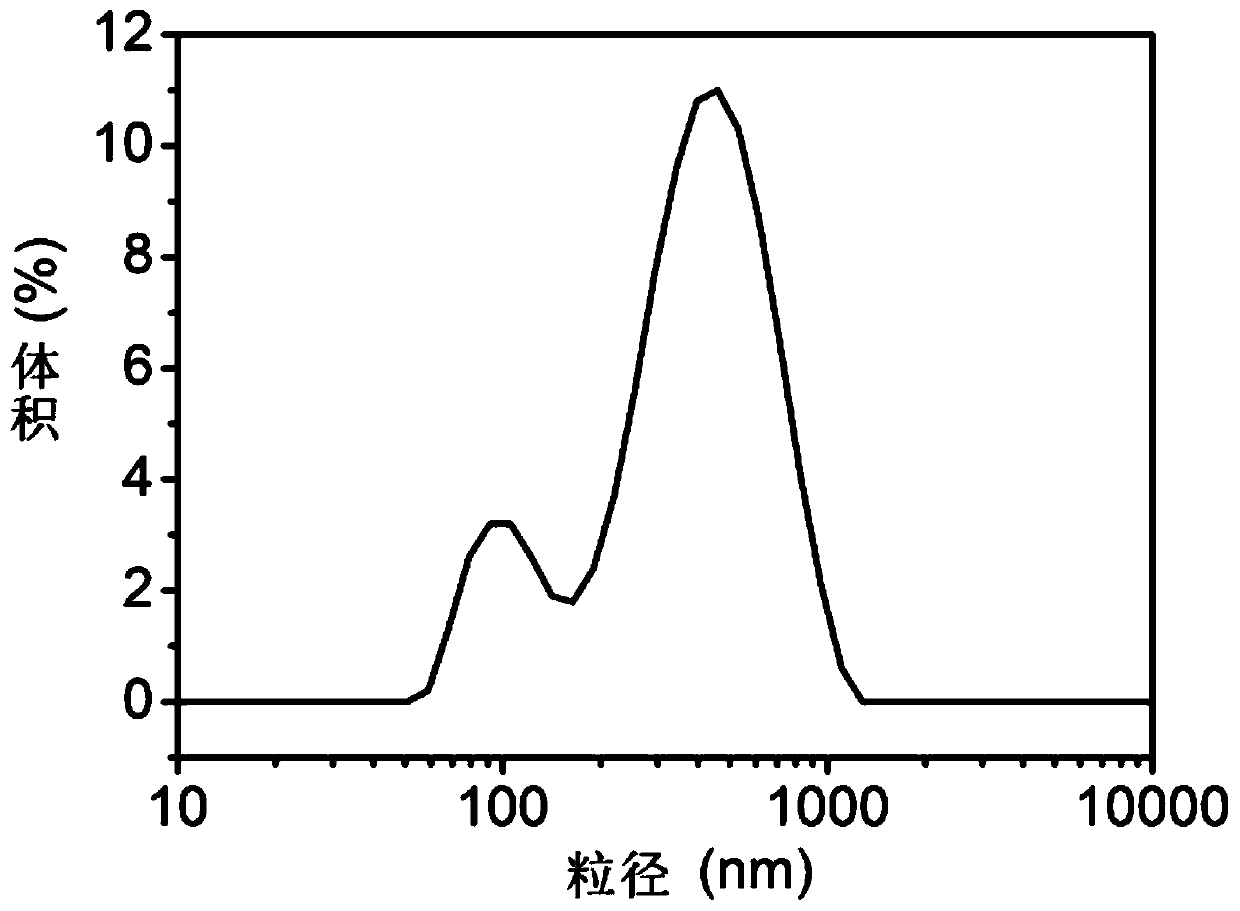

[0046] First, in an argon glove box, PVDF HSV 900 and nanometer Ta-LLZO ceramic powder (average particle size is 300nm, particle size distribution diagram as shown in Fig. figure 1 shown), and the lithium salt LiFSI was dissolved in NMP and stirred for 12 h to obtain a uniform viscous slurry.

[0047] Then, the slurry is scraped-coated on the PI porous membrane using a casting coating machine. During the casting coating process, the height of the membrane device is adjusted to be 10-500 microns, and the moving speed of the push rod is 1-50 mm / sec. Repeat scraping times 2 to 5 times, the amount of slurry coating is 1.95mg / cm 2 (The following examples are the same), air drying at 80°C for 12h, vacuum drying at 60°C for 24h to remove residual solvent, and obtain LLZO-PVDF composite solid electrolyte based on PI porous membrane.

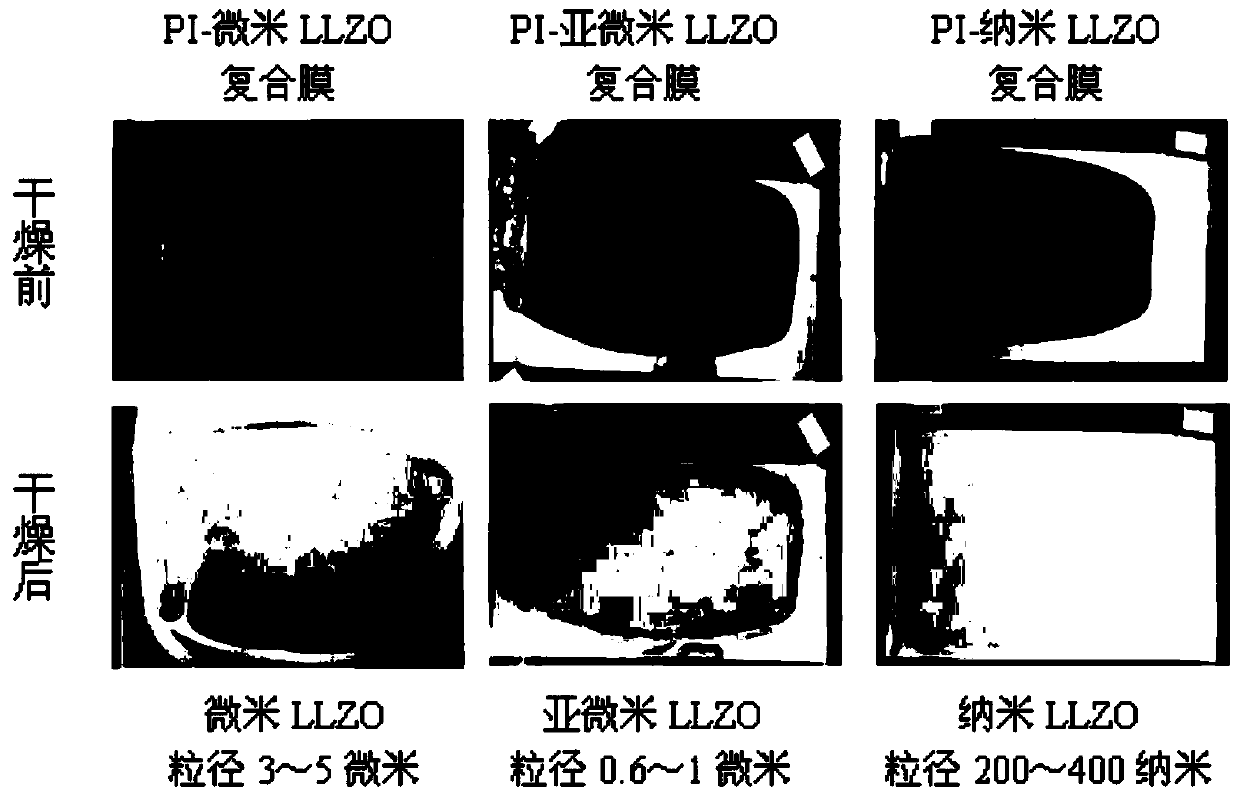

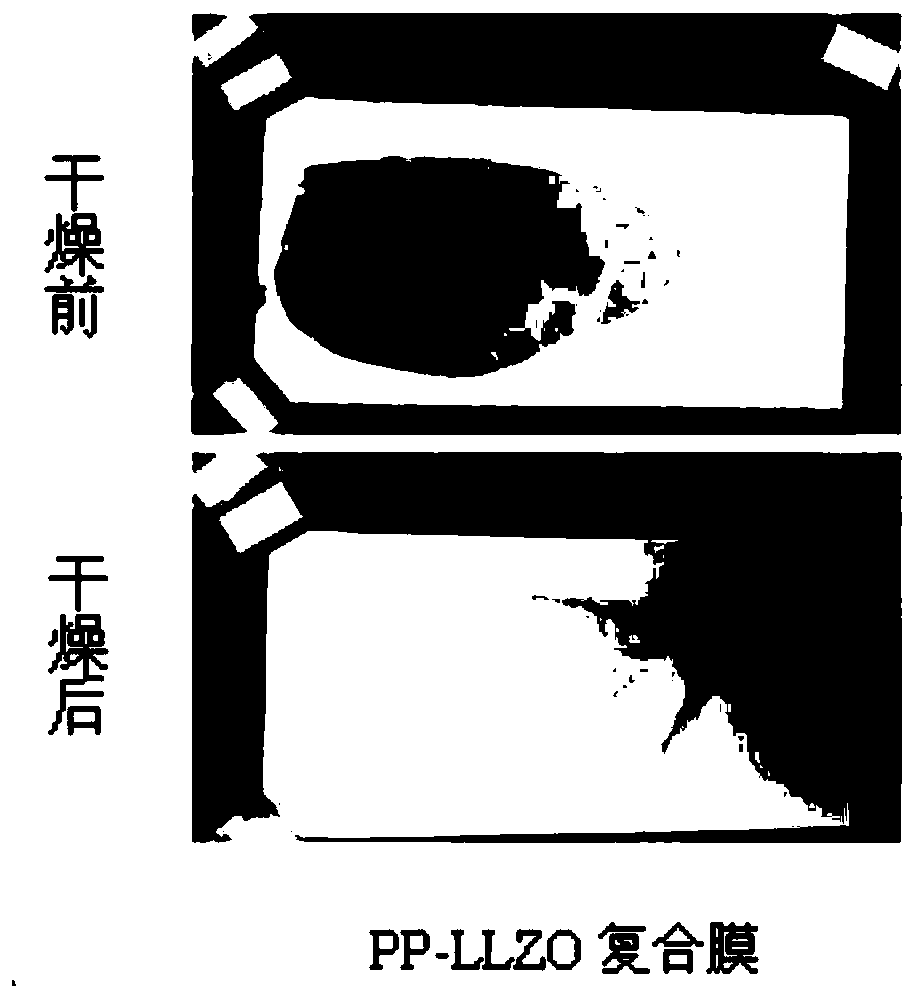

[0048] In addition, micron (particle size 3-5 micron) and submicron (particle size 0.6-1 micron) Ta-LLZO ceramic powders were used as fillers, respecti...

Embodiment 2

[0055] First, in an argon glove box, dissolve PVDF HSV 1800, nano-Al-LLZO ceramic powder (average particle size 200nm) and lithium salt LiTFSI in NMP with a mass ratio of 30:30:40, and stir for 15 hours to obtain Uniform viscous slurry.

[0056] Then, the slurry is coated on a PI porous membrane using a cast coater (surface morphology see Figure 4 Scanning electron microscope photographs, the scale is 5 microns), 80 ° C blast drying for 8 hours, 60 ° C vacuum drying for 24 hours to remove residual solvents, to obtain LLZO-PVDF composite solid electrolyte based on PI porous membrane; after the coating electrolyte slurry is dried, the surface Refer to the appearance Figure 5 . according to Figure 4 and Figure 5 In contrast, it can be seen that the electrolyte slurry is uniformly and densely filled in the pores of the PI porous membrane, forming a three-dimensional solid electrolyte.

[0057] The room temperature ionic conductivity of the composite electrolyte is 2.3×10 -...

Embodiment 3

[0060] First, in an argon glove box, PVDF 761A with a mass ratio of 30:40:30, nanometer Ta-LLZO ceramic powder (average particle size of 300nm, also known as LLZTO) and lithium salt LiClO 4 Dissolved in NMP, stirred for 10h to obtain a uniform viscous slurry.

[0061] Then, the slurry was coated on the PI porous membrane using a casting coater, air-dried at 60°C for 12h, and vacuum-dried at 70°C for 48h to remove residual solvents to obtain a LLZO-PVDF composite solid electrolyte based on the PI porous membrane (reference It is PI+LLZTO-PVDF composite electrolyte).

[0062] In addition, the composite electrolyte LLZTO-PVDF with no PI porous membrane as the substrate (the preparation method is the same as that with the PI porous membrane as the substrate, the difference is that the electrolyte without the PI membrane substrate is the electrolyte slurry by casting coating machine coated on a glass plate, and after drying, a self-supporting film without a PI film substrate is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com