Graphene@noble metal nanocluster@titanium dioxide three-layer structure catalyst, preparation method and application thereof

A technology of titanium dioxide and three-layer structure, which is applied in the field of direct synthesis of hydrogen peroxide from hydrogen and oxygen, and achieves the effects of low energy consumption, easy operation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is the preparation of flaky titanium dioxide, and the specific process is as follows:

[0053] First, 10 mmol of isoamyl titanate (TTIP) and 20 mmol of hydrochloric acid (HCl) were mixed together to form A solution. 1g of PEO20-PPO70-PEO20 (P123) and 9mL of ethanol were mixed to form B solution. Slowly add solution B to solution A and stir for 30 minutes, then pour it into ethylene glycol to form a mixed solution, transfer it to a reaction kettle, react at 140°C for 12 hours, then wash the product with ethanol, and dry it under vacuum at 80°C for 24 Hours, nano-flaky titanium dioxide was obtained.

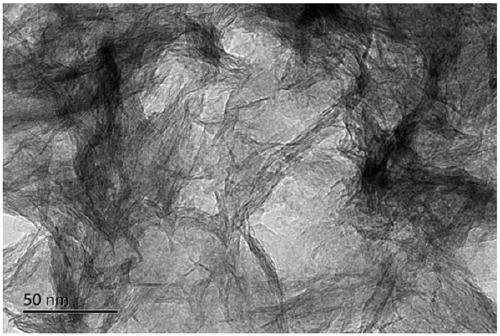

[0054] The nanosheets obtained in this embodiment are 500nm-5μm size flake materials, figure 1 From the TEM image of the material, it can be seen that the size of the prepared nano flakes is at least 1 μm.

Embodiment 2

[0056] Present embodiment is the preparation of (oxidized) graphene, and concrete process is as follows:

[0057] 1g of graphite and 2g of sodium nitrate (NaNO 3 ) were mixed in a 500mL beaker and stirred in an ice-water bath, and then 100mL of concentrated sulfuric acid was slowly added into it with vigorous stirring to avoid a sudden increase in temperature. After stirring for 1 hour, weigh 14.0g potassium permanganate (KMnO 4 ) into several portions, gradually add within half an hour to prevent the temperature from exceeding 20°C, control the temperature in time, stir for another hour, let the temperature rise to 40°C and react for 2 hours. Then add 100mL of water and raise the temperature to 90°C for half an hour. Finally, add a mixture of hydrogen peroxide and water to reduce unreacted high-valent manganese to divalent manganese ions, then wash repeatedly with a large amount of water, and dry in a vacuum to obtain two-dimensional (oxide) graphene.

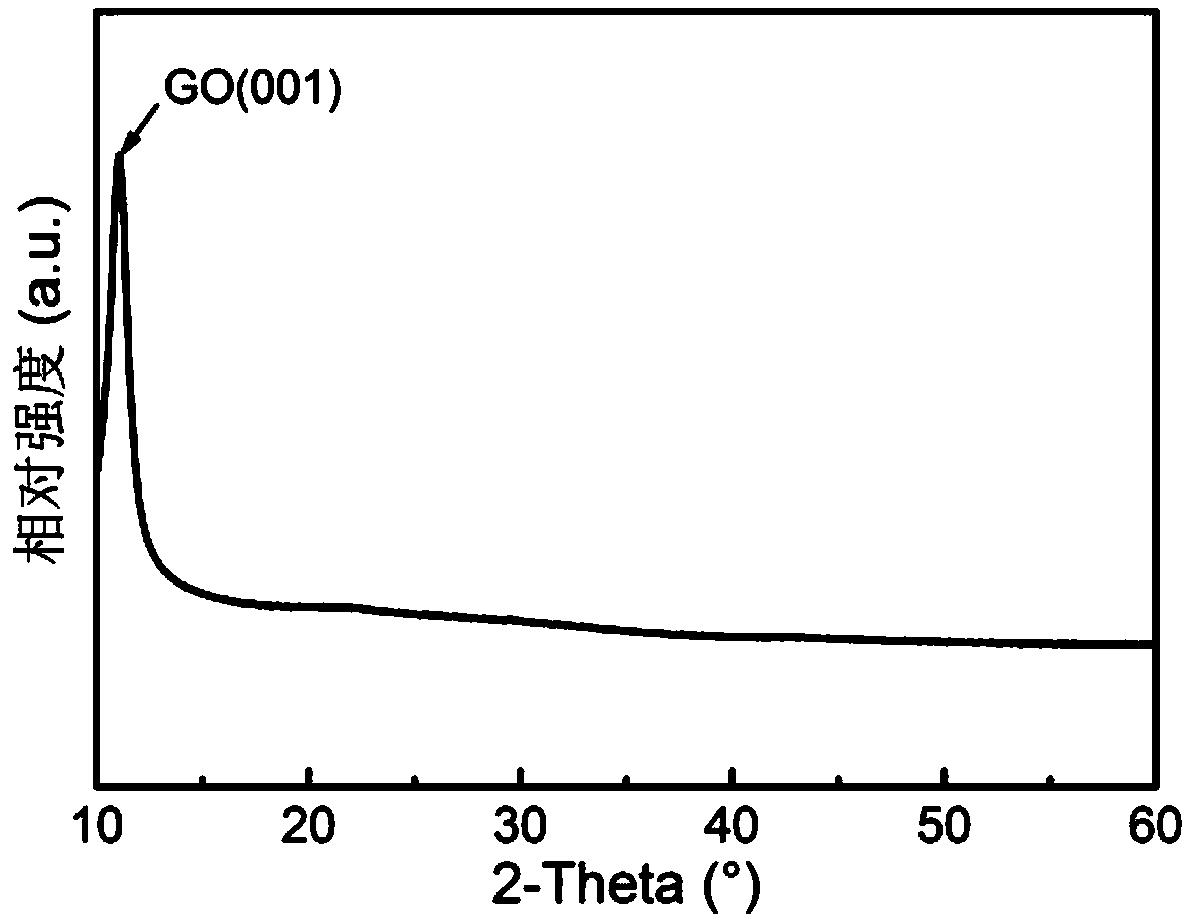

[0058] figure 2 I...

Embodiment 3

[0060] This embodiment is the preparation of (oxidized) graphene@noble metal nanoparticles@flaky titanium dioxide sandwich structure catalyst, the specific process is as follows:

[0061] The two-dimensional (oxidized) graphene prepared by embodiment 2 is dispersed in deionized water, stirred with magnetic force for 2 hours and ultrasonic until forming a uniform brown-black solution, and the weighed 50mg palladium chloride and 50mg chloroauric acid are dissolved in Stir in the graphene solution for 30 minutes, then add the newly prepared sodium borohydride solution, load the gold-palladium alloy particles on the surface of the graphene, and then add the pre-dispersed flaky titanium dioxide to it, and finally obtain the two-dimensional sandwich Structural Catalyst.

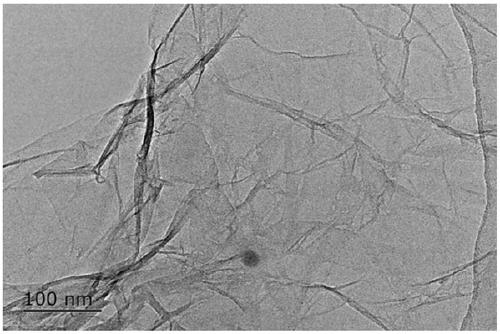

[0062] Figure 4 Shown is the XRD pattern of (oxidized) graphene@AuPd nanoparticles@flaky titania. Figure 5 The TEM image of the two-dimensional layered catalyst is shown. It can be seen that the gold-palladium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com