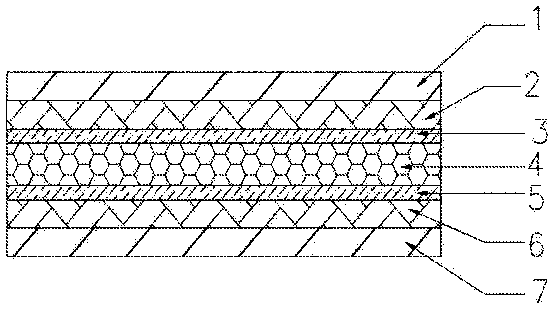

High-barrier seven-layer co-extrusion film and preparation method thereof

A high-barrier, co-extruded film technology, used in chemical instruments and methods, layered products, synthetic resin layered products, etc., to achieve the effects of improving molding processability, improving thermal stability, and good support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

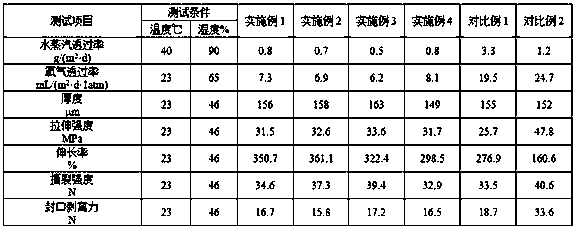

Embodiment 1

[0029] At room temperature, put 95.7 parts of isophorone diisocyanate and 0.259 parts of dibutyltin dilaurate into the reaction kettle in sequence, pass through dry compressed air, start stirring, and add 528.1 parts of fluorine-containing polyether diol in 3 batches ( Hydroxyl value 61mg·KOH / g). Control the reaction temperature not to exceed 45°C. After the feeding was completed, the reaction was carried out at 40-45° C., and the NCO content was detected by the di-n-butylamine-toluene method after 1 h. When the NCO value reaches 1.93%, add 20.98 parts of 2-ethyl-1,3-hexanediol, raise the temperature to 75°C, and react until the NCO content is 0. Cool down to 40°C and discharge to obtain fluorine-containing polyurethane elastomer.

[0030] Put metallocene polyethylene and low density polyethylene in a mass ratio of 6:4 into a high-speed mixer, and mix for 7 to 8 minutes at 1000 rpm to obtain a polyolefin layer raw material. Put the fluorine-containing polyurethane elastomer...

Embodiment 2

[0033] At room temperature, 100.6 parts of isophorone diisocyanate and 0.312 parts of dibutyltin dilaurate were successively put into the reaction kettle, dry compressed air was passed through, stirring was started, and 708.56 parts of fluorine-containing polyether diol were added in 3 batches ( Hydroxyl value 61mg·KOH / g). Control the reaction temperature not to exceed 45°C. After the feeding was completed, the reaction was carried out at 40-45° C., and the NCO content was detected by the di-n-butylamine-toluene method after 1 h. When the NCO value reaches 3.68%, add 33.08 parts of 2-ethyl-1,3-hexanediol, raise the temperature to 75°C, and react until the NCO content is 0. Cool down to 40°C and discharge to obtain fluorine-containing polyurethane elastomer.

[0034] Put metallocene polyethylene and low density polyethylene in a mass ratio of 6.5:3.5 into a high-speed mixer, and mix for 7 to 8 minutes at 1000 rpm to obtain a polyolefin layer raw material. Put the fluorine-co...

Embodiment 3

[0037] At room temperature, put 93.9 parts of toluene diisocyanate (TDI-80) and 0.230 parts of dibutyltin dilaurate into the reaction kettle in sequence, pass in dry compressed air, start stirring, and add 806.58 parts of fluorine-containing polyether binary in 5 batches. Alcohol (hydroxyl value 50mg·KOH / g). Control the reaction temperature not to exceed 50°C. After the feeding was completed, the reaction was carried out at 40-50° C., and the NCO content was detected by the di-n-butylamine-toluene method after 1 h. When the NCO value reaches 1.68%, add 28.81 parts of 2-butyl-2-ethyl-1,3-propanediol, raise the temperature to 75°C, and react until the NCO content is 0. Cool down to 40°C and discharge to obtain fluorine-containing polyurethane elastomer.

[0038] Put metallocene polyethylene and low density polyethylene in a mass ratio of 6:4 into a high-speed mixer, and mix for 7 to 8 minutes at 1000 rpm to obtain a polyolefin layer raw material. Put the fluorine-containing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com