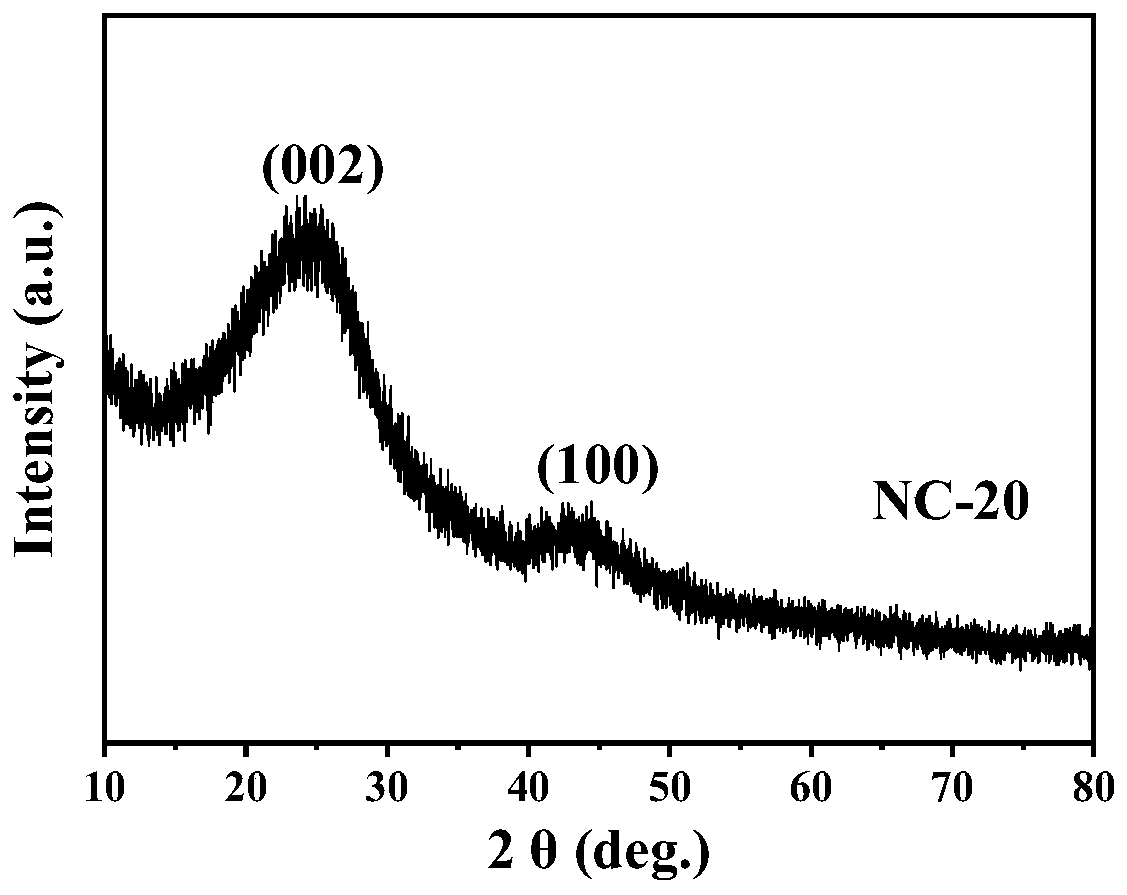

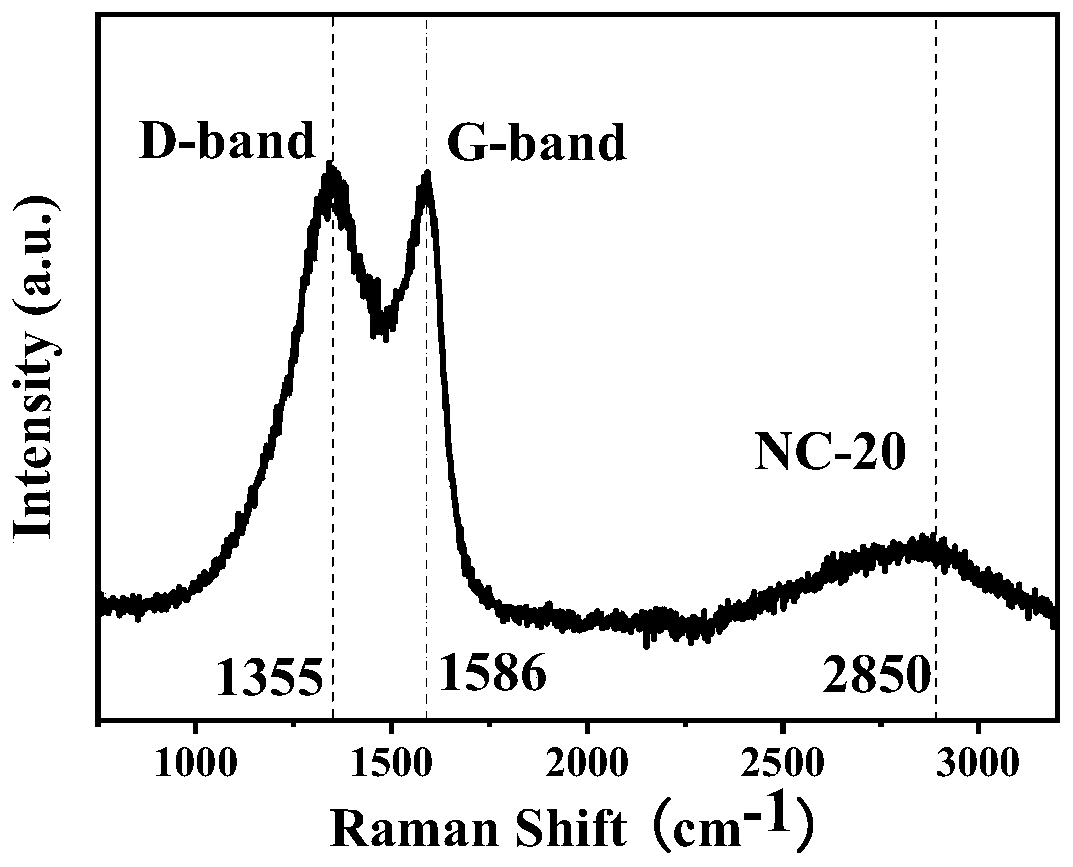

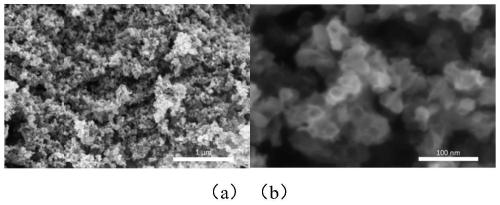

Nitrogen-doped porous nano carbon material, preparation method thereof and application of same as lithium ion battery negative electrode material

A nano-carbon material and nitrogen-doped technology, which is applied in the direction of nano-carbon, battery electrodes, secondary batteries, etc., can solve the problem of the inability to achieve precise control of nitrogen doping amount, the difficulty in meeting the demand of nitrogen doping amount, and the restriction of nitrogen-doped carbon Negative electrode materials and other issues, to achieve the effect of facilitating the contact between the electrolyte and the electrode, good product stability, and increasing the number of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First measure 125mL of deionized water, weigh 0.59g of potassium permanganate and pour it into deionized water, ultrasonicate for 5 minutes until the potassium permanganate is completely dissolved, and prepare a 0.03mol / L potassium permanganate solution; measure 125mL Deionized water, take by weighing 0.94g manganese nitrate tetrahydrate and be dissolved in above-mentioned deionized water, be mixed with the manganese nitrate solution of 0.03mol / L; Potassium permanganate solution is poured in the manganese nitrate solution, after stirring and mixing, Measure 340 microliters of aniline into the mixed solution, and stir for 30 minutes; then transfer the solution to the lining of the hydrothermal reaction kettle, put it into a heating oven, and carry out the hydrothermal reaction. The reaction time is 6 hours, and the reaction temperature is 180°C; After the reaction, the liquid was taken out and centrifuged, the supernatant was poured off, and the precipitate was washed wit...

Embodiment 2

[0042]First measure 125mL of deionized water, weigh 0.59g of potassium permanganate and pour it into deionized water, ultrasonicate for 5 minutes until the potassium permanganate is completely dissolved, and prepare a 0.03mol / L potassium permanganate solution; measure 125mL Deionized water, weigh 0.47g manganese chloride and dissolve it in the above-mentioned deionized water to prepare a 0.03mol / L manganese nitrate solution; pour the potassium permanganate solution into the manganese nitrate solution, and after mixing evenly, measure Add 340 microliters of aniline to the mixed solution and stir for 30 minutes; then transfer the solution to the lining of the hydrothermal reaction kettle, put it in a heating oven, and carry out hydrothermal reaction. The reaction time is 10 hours, and the reaction temperature is 150°C; After the end, the liquid was taken out and centrifuged, and the supernatant was poured off, and the precipitate was washed with deionized water (four times); fina...

Embodiment 3

[0045] First measure 125mL of deionized water, weigh 0.59g of potassium permanganate and pour it into deionized water, ultrasonicate for 5 minutes until the potassium permanganate is completely dissolved, and prepare a 0.03mol / L potassium permanganate solution; measure 125mL Deionized water, weigh 0.94g manganese nitrate tetrahydrate and dissolve in the above-mentioned deionized water to prepare a 0.03mol / L manganese chloride solution; pour the potassium permanganate solution into the manganese chloride solution, and stir to mix evenly Finally, measure 340 microliters of aniline and add it into the mixed solution, and stir for 30 minutes;

[0046] Then transfer the solution to the lining of the hydrothermal reaction kettle, put it into a heating oven, and carry out the hydrothermal reaction. The reaction time is 6 hours, and the reaction temperature is 180°C. After the reaction is completed, the liquid is taken out and centrifuged, and the supernatant is poured out After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com