Preparation method of novel mildew-proof environment-friendly coating

An environmentally friendly coating, a new technology, applied in antifouling/underwater coatings, starch coatings, coatings, etc., can solve the problems of low bond strength, poor adhesion, easy to mold, etc., achieve good results, prevent coatings from mildew, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

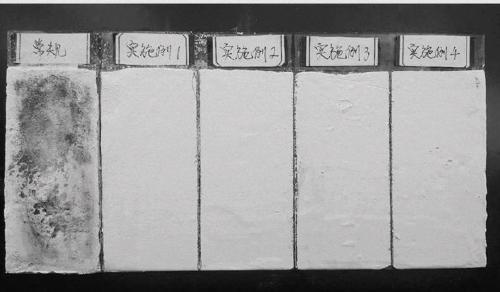

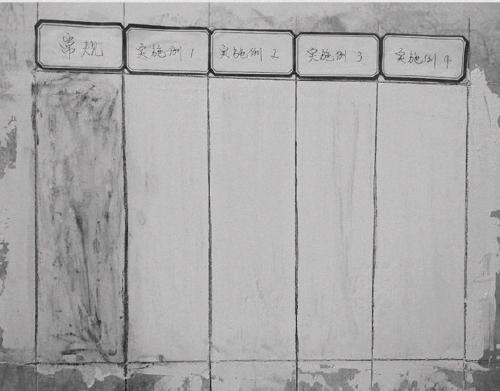

Embodiment 1

[0020] 150 parts of light calcium carbonate, 30 parts of heavy calcium carbonate, 20 parts of gypsum powder, 20 parts of talcum powder, 15 parts of dispersant, 15 parts of lime calcium powder, 10 parts of pregelatinized starch, 3 parts of hydroxypropyl methylcellulose 1 part, 3 parts of acrylic acid copolymer rubber powder, 1 part of hydrophobic agent, 0.5 part of compound antifungal agent, 0.5 part of nano-titanium dioxide, 0.1 part of nano-zinc oxide, prepared according to the above steps.

Embodiment 2

[0022] 120 parts of light calcium carbonate, 35 parts of heavy calcium carbonate, 20 parts of gypsum powder, 25 parts of talcum powder, 15 parts of dispersant, 12 parts of lime calcium powder, 9 parts of pregelatinized starch, 5 parts of hydroxypropyl methylcellulose 1 part, 1 part of acrylic copolymer rubber powder, 2 parts of hydrophobic agent, 1 part of compound antifungal agent, 1 part of nano-titanium dioxide, and 0.2 part of nano-zinc oxide.

Embodiment 3

[0024] 120 parts of light calcium carbonate, 40 parts of heavy calcium carbonate, 25 parts of gypsum powder, 25 parts of talcum powder, 20 parts of dispersant, 12 parts of lime calcium powder, 8 parts of pregelatinized starch, 4 parts of hydroxypropyl methylcellulose 2 parts, 2 parts of acrylic copolymer rubber powder, 2 parts of hydrophobic agent, 0.8 part of compound antifungal agent, 0.8 part of nano-titanium dioxide, and 0.2 part of nano-zinc oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com