Citric acid soluble granular fertilizer and preparation process thereof

A technology of granular fertilizer and preparation process, applied in ammonium salt fertilizer, fertilizer mixture, solid/semi-solid fertilizer and other directions, can solve the problems of inability to be absorbed and utilized by plants, difficult to be absorbed and utilized by plants, and high chloride ion content, so as to promote photosynthesis. and nutrient uptake, increase total nutrient content, and improve soil conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

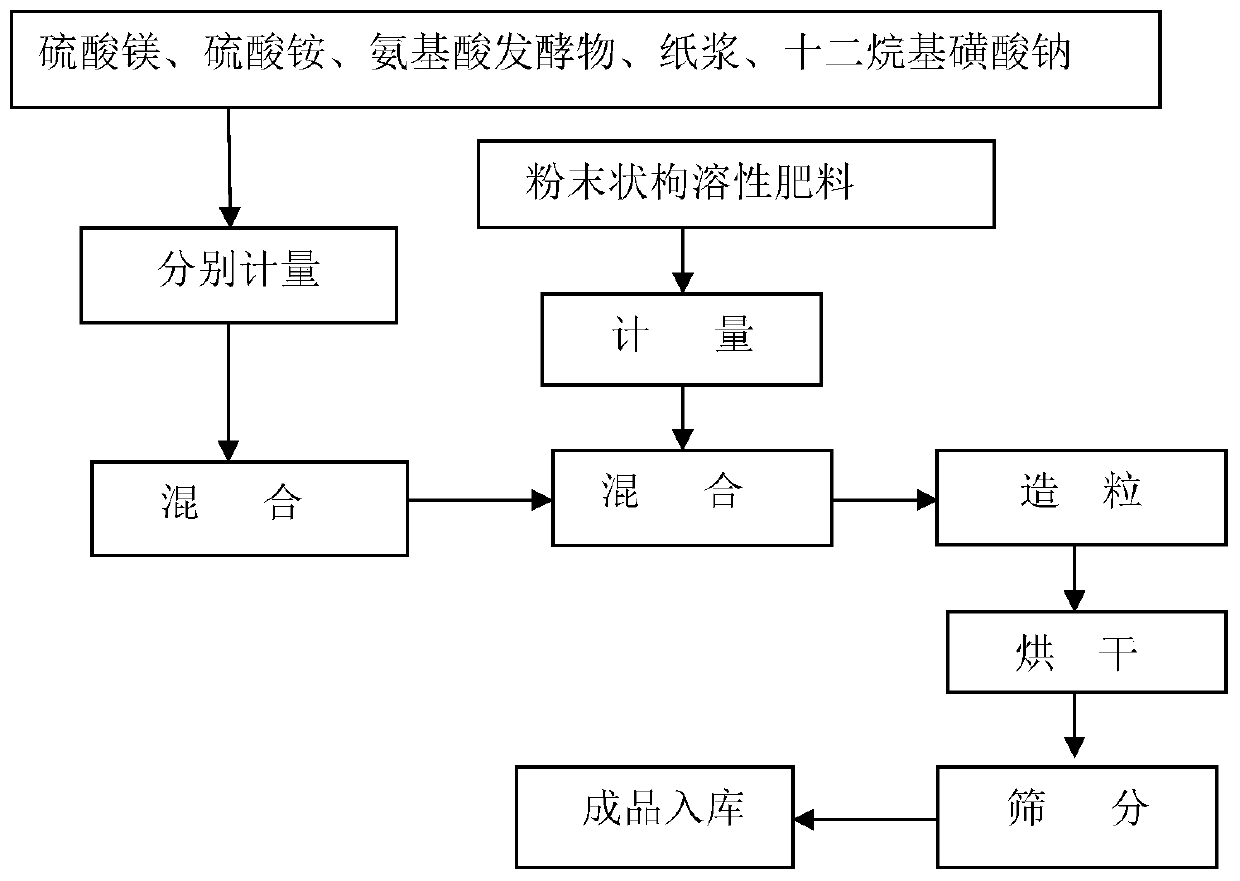

Method used

Image

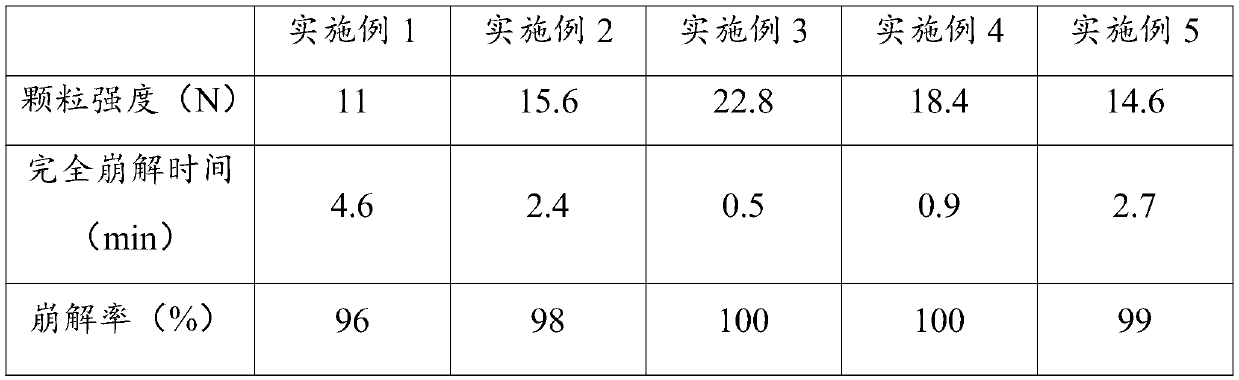

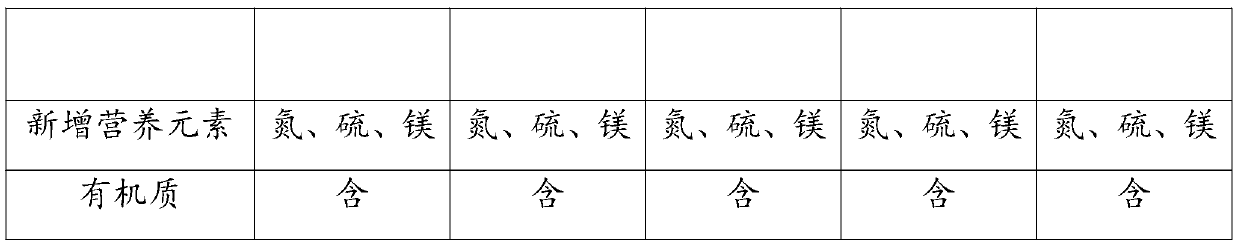

Examples

Embodiment 1

[0032] The preparation technology of the citrate soluble granular fertilizer that the embodiment of the present invention 1 provides comprises the following steps:

[0033] (1) The inorganic disintegrating materials magnesium sulfate, ammonium sulfate and organic disintegrating materials amino acid fermentation products, pulp, sodium dodecylsulfonate and citric acid soluble fertilizer used as binders are respectively pulverized and pretreated. Magnesium sulfate, ammonium sulfate, amino acid fermentation products, pulp, sodium dodecylsulfonate, citrate-soluble fertilizers have a particle size greater than or equal to 70 mesh;

[0034] (2) mixing inorganic disintegrating materials magnesium sulfate and ammonium sulfate according to a weight ratio of 2:98 to obtain a mixture of inorganic disintegrating materials;

[0035] (3) mixing the organic disintegrating material amino acid fermented product, pulp, and sodium dodecylsulfonate in a weight ratio of 10:10:80 to obtain an organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com