Wafer full laser dicing method

A cutting method and wafer technology, applied in the field of wafer processing, can solve the problems of inability to meet processing standards, low production efficiency, low dielectric constant, etc., to reduce thermal effects, reduce the loss of cutting grooves, and increase the number of chips Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of laser full cutting method of wafer, comprises the following steps:

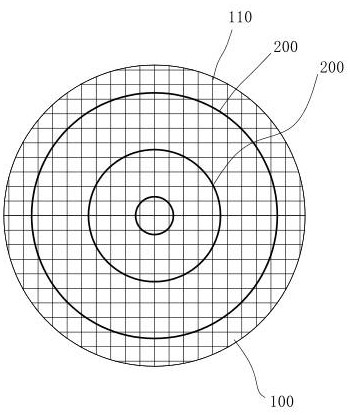

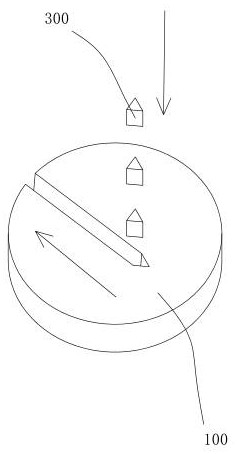

[0024] First, calibrate and measure the center of gravity of the wafer; then load the wafer; since the thinner the wafer, the easier it is to warp, and the center of gravity of the wafer will change after warping. Use the center of gravity to adjust the calibrator to confirm the center of gravity of the wafer. After confirming the center of gravity, send the wafer to the vacuum table with X, Y direction movement and rotation for vacuum adsorption through a fully automatic manipulator; in this step, by adding the link of center of gravity calibration It can ensure the accuracy of the placement position of the wafer on the vacuum suction table and the uniformity of adsorption, which is beneficial to reduce the fragmentation rate.

[0025] Then, after the wafer is absorbed and flattened, the X and Y of the platform are moved to the positioning calibration vision to detect and posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com