Gallium oxide semiconductor structure, solar-blind photodetector and preparation method

A photodetector, gallium oxide technology, applied in semiconductor devices, photovoltaic power generation, circuits, etc., can solve the problems of long switching time, failure to realize high-performance gallium oxide solar-blind photodetector preparation, and reduce detector responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

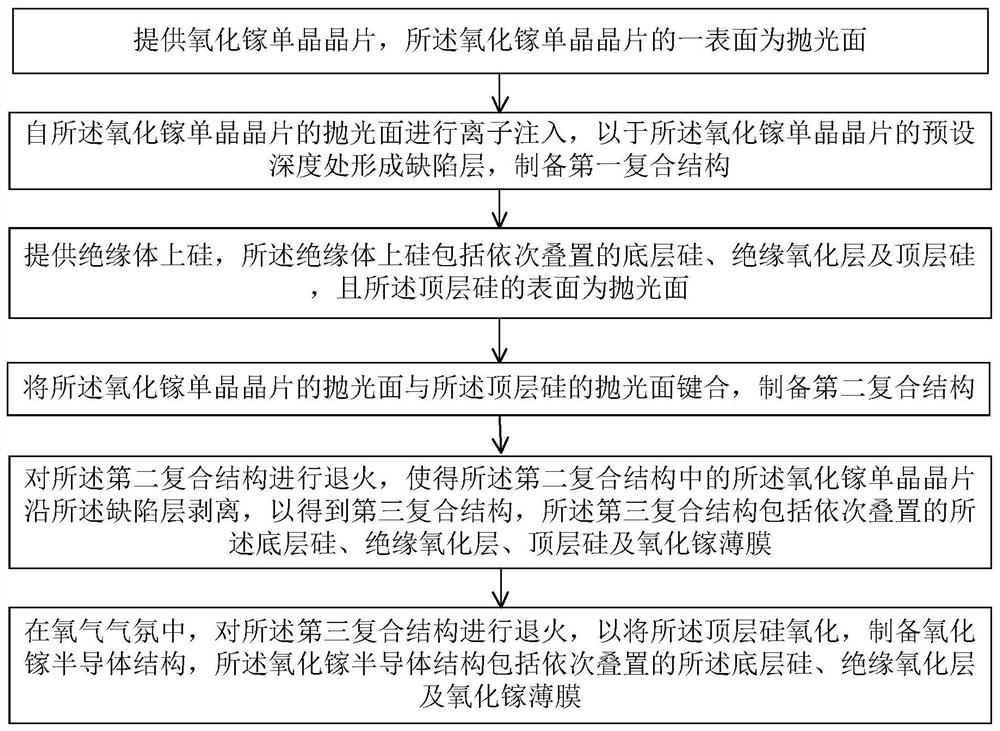

Method used

Image

Examples

preparation example Construction

[0075] This embodiment also provides a method for preparing a solar-blind photodetector, comprising the following steps:

[0076] The gallium oxide semiconductor structure is prepared by the above preparation method of the gallium oxide semiconductor structure;

[0077] Fabricate interdigitated electrodes on the gallium oxide semiconductor structure.

[0078] As an example, the width of the interdigital electrodes is 2 μm to 500 μm, such as 50 μm, 100 μm, 200 μm, 300 μm, 400 μm, etc., and the length is 50 μm to 5000 μm, such as 100 μm, 500 μm, 1000 μm, 3000 μm, etc. The distance between the interdigital electrodes 2 μm to 1000 μm, such as 50 μm, 100 μm, 500 μm, 800 μm, etc.

[0079]As an example, the interdigital electrodes include one of Au / Ti interdigital electrodes, Au / Ni interdigital electrodes, Au interdigital electrodes, and Pt interdigital electrodes, wherein, in the Au / Ti interdigital electrodes, Au The thickness of Ti is 50nm~300nm, such as 100nm, 150nm, 200nm, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com