Composite negative plate and preparation method and application thereof

A negative electrode sheet and negative electrode technology, which is applied in the field of battery negative electrodes, can solve the problems of battery cycle performance degradation, metal negative electrodes are easily crushed and broken, and achieve the effect of improving rate performance, reducing side reaction process, and increasing ion diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

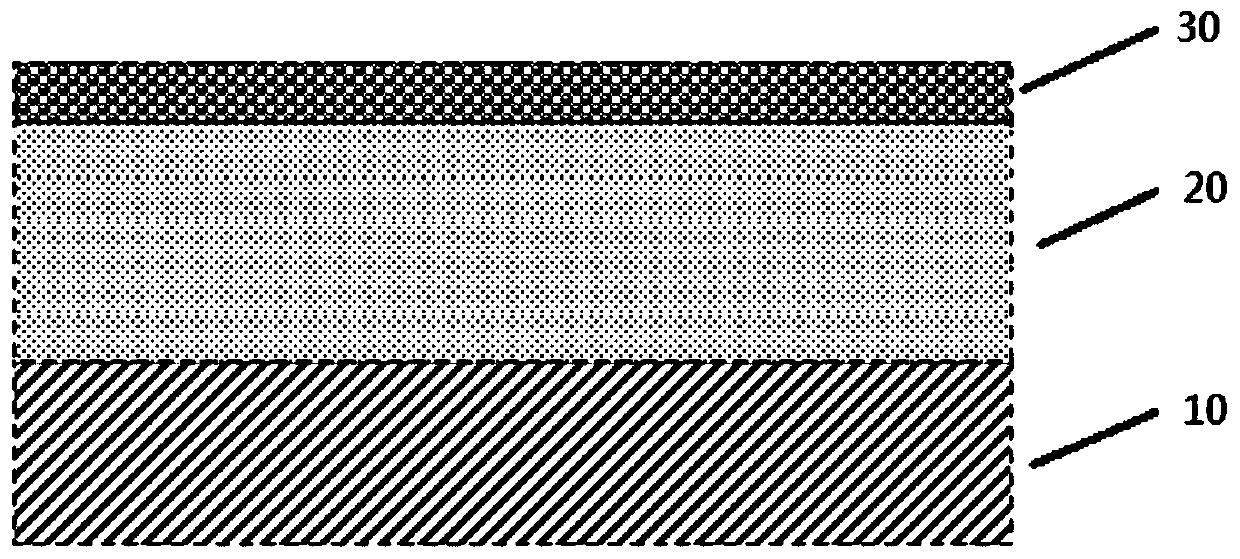

[0061] Another aspect of the embodiments of the present invention provides a method for preparing a composite aluminum negative electrode sheet, comprising the following steps:

[0062] S01. Provide a metal foil, and sequentially perform pretreatment, glow cleaning and ion etching cleaning on the metal foil;

[0063] S02. The solid electrolyte target deposits a solid electrolyte film layer on the surface of the metal foil;

[0064] S03. Depositing a diamond-like carbon film layer on the surface of the solid electrolyte film layer.

[0065] Specifically, in the above step S01, the selection of the metal foil and its thickness is as described above. If the thickness of the metal foil is 20 microns to 150 microns, preferably, the thickness of the metal foil is 40 microns to 60 microns, more preferably 50 microns.

[0066] Perform pretreatment, glow cleaning and ion etching cleaning on the provided metal foil in sequence, and remove organic matter on the surface of the metal foi...

Embodiment 1

[0094] A preparation method of a composite aluminum negative plate, comprising the following steps:

[0095] S11. Provide aluminum foil, and sequentially perform pretreatment, glow cleaning and ion etching cleaning on the aluminum foil; specifically:

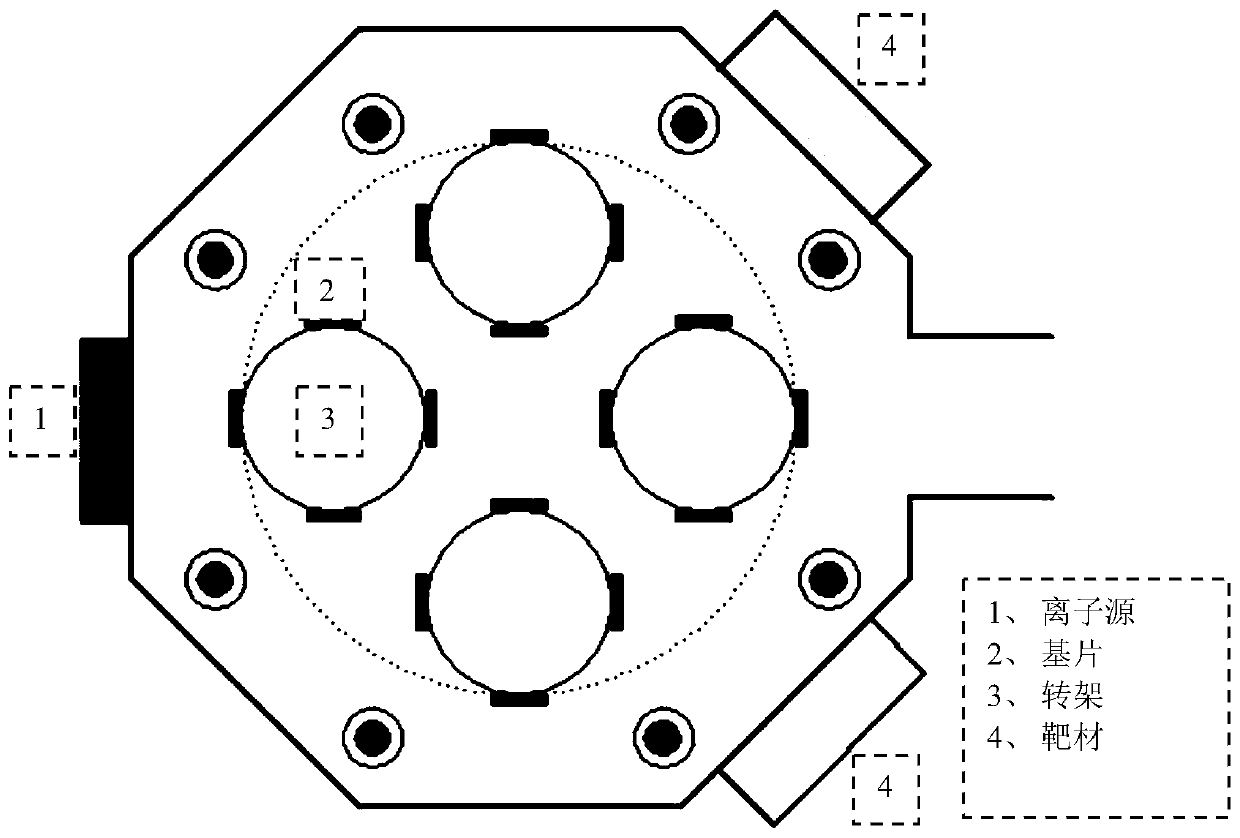

[0096] Put the aluminum foil in distilled water for ultrasonic cleaning, then put the aluminum foil in acetone solution for ultrasonic cleaning, and then put the aluminum foil in absolute ethanol solution for ultrasonic cleaning; after cleaning, dry the substrate with dry nitrogen The surface is blown dry, and finally the sample is dried in a blast drying oven at 80-150°C. Before glow cleaning, adjust the equipment parameters, specifically, fix the dried aluminum foil on the turntable in the magnetron sputtering coating equipment; close the vacuum chamber door, turn on the water cooler to set the ion source, multi-arc The target, the molecular pump, and the water circuit of the vacuum chamber are connected, and the main power s...

Embodiment 2

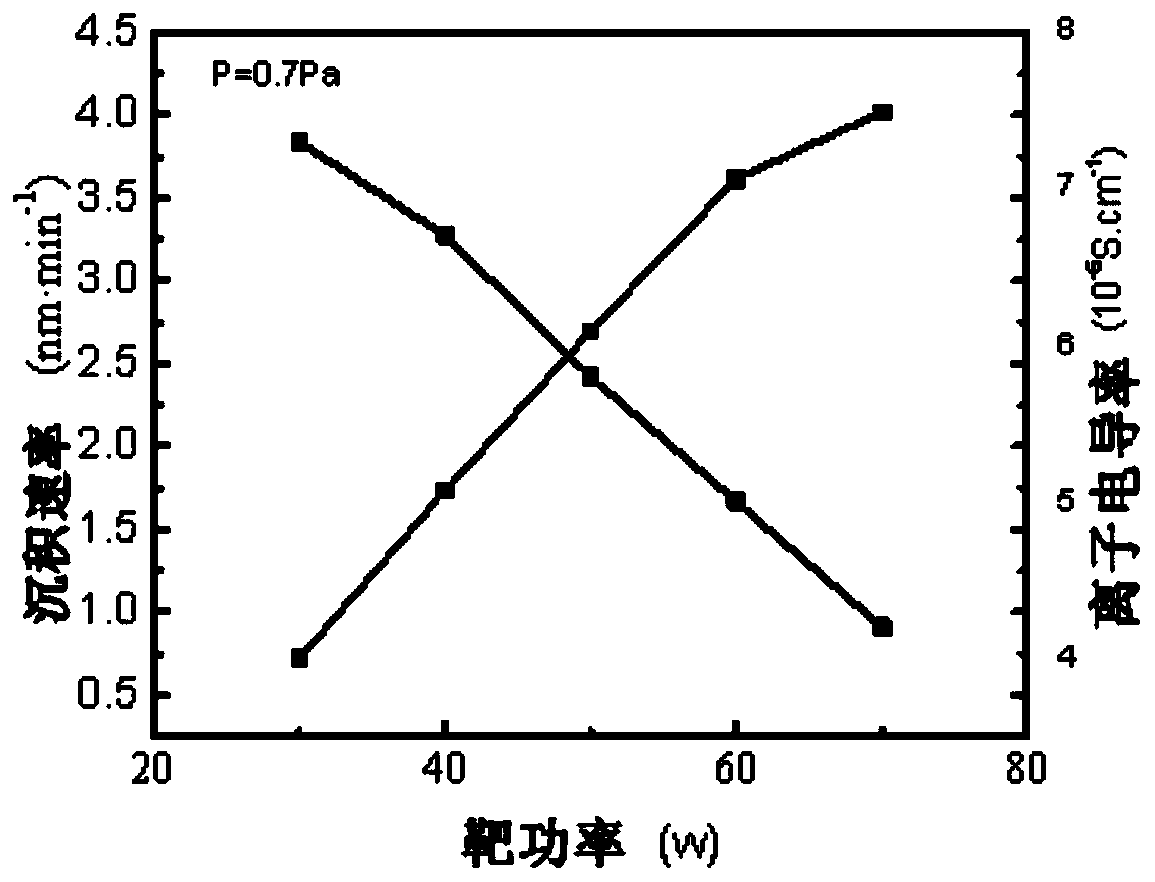

[0103] A preparation method of a composite aluminum negative electrode sheet, the difference from Example 1 lies in: the lithium phosphine oxynitride layer power is 50W, the nitrogen partial pressure is 0.5Pa, the bias voltage is -150V, and the time is 120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com