A device and method for processing raw material gas from thionyl chloride production

A technology of thionyl chloride and treatment method, applied in chemical instruments and methods, separation methods, sulfur trioxide/sulfuric acid and other directions, can solve the problems of high impurity content and low purity of sulfur dioxide, and achieve low waste liquid generation and reduction. Sedimentation, the effect of improving the discharge situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

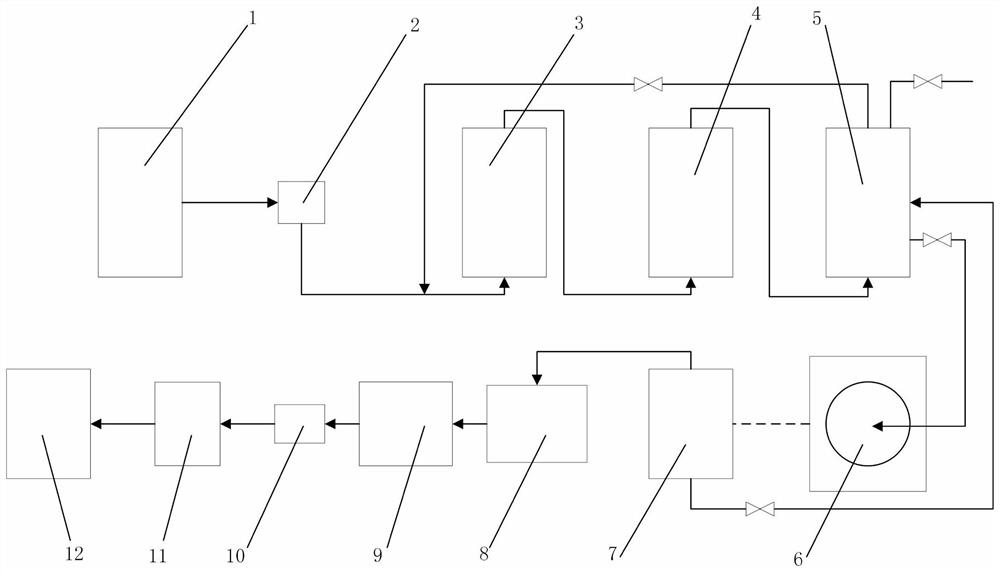

[0082] S1, get the sulfur dioxide gas purchased from the market, use drying device 8 to dry the sulfur dioxide gas, the composition in the sulfur dioxide gas after drying is sulfur dioxide (99.5w%), dust (0.42w%), moisture (0.02w%) , non-condensable gas and other substances (0.06w%); filter sulfur dioxide by air filter device 9 to obtain pure sulfur dioxide gas;

[0083] S2. At normal temperature, pressurize the compressor 10, condense the sulfur dioxide gas through the condenser 11 to obtain liquid sulfur dioxide, and transport the liquid sulfur dioxide to the storage tank 12 as the raw material gas for the production of thionyl chloride.

[0084] Liquid sulfur dioxide was tested for purity, and the results are shown in Table 1.

Embodiment 2

[0086] S1. Collect the tail gas in the production process of thionyl chloride to obtain a mixed gas A; wherein the mixed gas A includes sulfur dioxide, chlorine, hydrogen chloride, sulfur monochloride vapor, sulfur dichloride vapor, and thionyl chloride vapor;

[0087] S2. Transport the mixed gas A to the first absorption tank 3 through a pneumatic diaphragm pump, and use carbon disulfide to perform first-stage absorption on the mixed gas A to remove sulfur monochloride vapor, sulfur dichloride vapor, thionyl chloride vapor, Chlorine, to obtain mixed gas B;

[0088] S3, transporting the mixed gas B to the second absorption tank 4, using ethylene glycol to perform second-stage absorption on the mixed gas B, removing hydrogen chloride, and obtaining sulfur dioxide-enriched gas;

[0089] S4. Pass the sulfur dioxide-rich gas into the barium hydroxide and barium chloride composite solution in the third absorption kettle 5 to obtain a barium sulfite-containing slurry, and use the ce...

Embodiment 3

[0095] S1. Collect the tail gas in the production process of thionyl chloride to obtain a mixed gas A; wherein the mixed gas A includes sulfur dioxide, chlorine, hydrogen chloride, sulfur monochloride vapor, sulfur dichloride vapor, and thionyl chloride vapor;

[0096] S2. Transport the mixed gas A to the first absorption tank 3 through a pneumatic diaphragm pump, and use carbon tetrachloride to perform first-stage absorption on the mixed gas A to remove sulfur monochloride vapor, sulfur dichloride vapor, and chlorinated Sulfone steam, chlorine gas, obtain mixed gas B;

[0097] S3. Transport the mixed gas B to the second absorption tank 4, and use the 1,2-propanediol and 1,2-butanediol mixed reagent with a volume ratio of 2:1 to perform second-stage absorption on the mixed gas B to remove hydrogen chloride , to obtain sulfur dioxide-rich gas;

[0098] S4. Pass the sulfur dioxide-rich gas into the barium hydroxide and barium chloride composite solution in the third absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com