Polyvinylidene fluoride membrane with differentiated double-sided hydrophobicity as well as preparation method and application thereof

A polyvinylidene fluoride membrane and polyvinylidene fluoride-based membrane technology are applied in the field of polyvinylidene fluoride membrane and its preparation, which can solve the problem of increasing gas mass transfer resistance, decreasing mass transfer rate, and inability of a membrane contactor to run stably for a long time. and other problems, to achieve the effect of reducing mass transfer resistance, avoiding membrane wetting, and excellent desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the present invention, the preparation method of the hydrophobic nanoparticle-polymer suspension preferably comprises the following steps:

[0045] After mixing the non-solvent and the polymer, the first ultrasound and the first stirring are performed in sequence to obtain a mixed solution;

[0046] The solvent and the hydrophobic nanoparticles are sequentially added to the mixed solution, and then the second ultrasonic wave and the second stirring are sequentially performed to obtain a hydrophobic nanoparticle-polymer suspension.

[0047] In the present invention, the time of the first ultrasonic is preferably 0.5~2h, the time of the first stirring is preferably 0.5~2h; the time of the second ultrasonic is preferably 10~30min, and the time of the second stirring is preferably 12 ~16h; both the first stirring and the second stirring are preferably magnetic stirring; after the mixed solution is obtained, the present invention preferably slowly adds the solvent to the ...

Embodiment 1

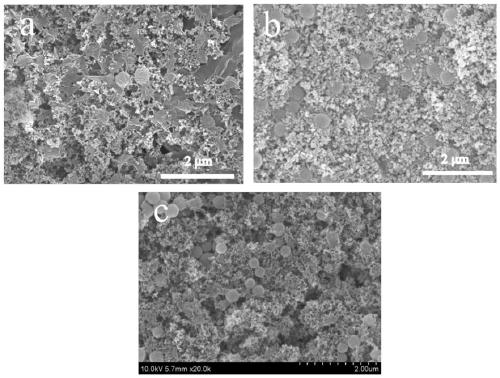

[0068] The superhydrophobic layer of polyvinylidene fluoride membrane with differential hydrophobicity on both sides is composed of hydrophobic nano-silica (particle size: 30nm) and PVDF (polyvinylidene fluoride film) particles (particle size: 1μm), in which the hydrophobic nanometer The mass ratio of silicon oxide and polyvinylidene fluoride is 1:2.

[0069] The preparation method of the polyvinylidene fluoride film with differential hydrophobicity on both sides is as follows:

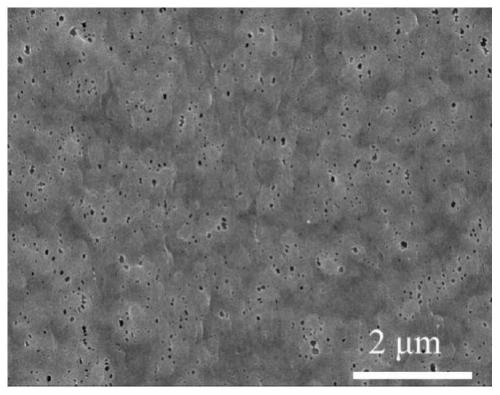

[0070] (1) Preparation of polyvinylidene fluoride-based film: Add 16wt.% polyvinylidene fluoride, 8wt.% ethylene glycol and 86wt.% dimethylacetamide into a three-necked flask, and stir evenly at 60°C for more than 6 hours to obtain cast Membrane fluid. The polyvinylidene fluoride-based membrane was prepared by the immersion precipitation phase inversion method (the operation method was the same as step (2) of Comparative Example 1).

[0071] (2) Preparation of silica-polyvinylidene fluoride suspensi...

Embodiment 2

[0082]The superhydrophobic layer of polyvinylidene fluoride film with differential hydrophobicity on both sides is composed of hydrophobic nano-silica (particle size 30nm) and PVDF particles (particle size 1μm), in which the mass of silicon dioxide and polyvinylidene fluoride The ratio is 1:1.

[0083] The preparation method of the polyvinylidene fluoride film with differential hydrophobicity on both sides is as follows:

[0084] (1) Preparation of polyvinylidene fluoride-based film: refer to Example 1, and obtain a polyvinylidene fluoride-based film according to its preparation method.

[0085] (2) The preparation of the silica-polyvinylidene fluoride suspension is the same as that in Example 1, except that: 1wt.% hydrophobic nano-silica, 83wt.% dimethylacetamide.

[0086] (3) The spin-coating steps were the same as in Example 1, and a polyvinylidene fluoride film with differentiated hydrophobicity on both sides was prepared.

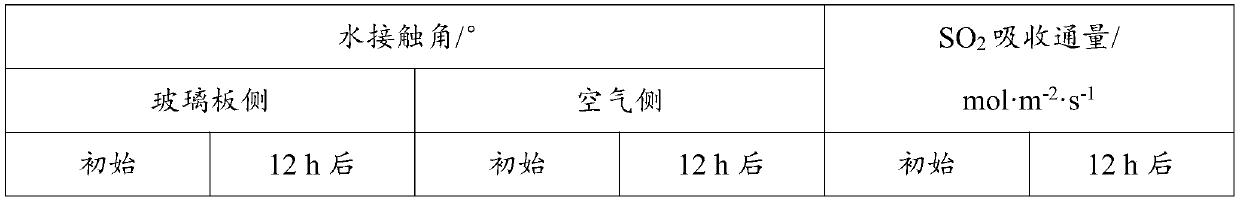

[0087] Performance Testing:

[0088] Observat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com