Preparation method and application of supported cobalt/carbon nano tube material derived from zeolite imidazole framework material

A zeolite imidazole framework and carbon nanotube technology, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, the preparation of oxidation reactions, etc., can solve the problem of low conversion rate KA oil selectivity, unsatisfactory value, low catalytic performance, etc. problem, to achieve the effect of good industrial application prospect, low synthesis cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Supported Co-Co with controllable cobalt valence state derived from zeolite imidazole framework material x o y The preparation method of / CN material specifically comprises the following steps:

[0039] Step (1), take a certain amount of cobalt nitrate and dissolve it in water and mark it as A solution, take a certain amount of dimethylimidazole and triethylamine and dissolve it in water and mark it as B solution, A solution and B solution are uniformly mixed, Wherein the mass ratio of cobalt nitrate, dimethylimidazole, triethylamine and water in the mixed solution=1.0:2.3:2.5:69.7, stirred at room temperature for 12-36 hours; centrifuged, washed; the obtained precipitate was dried and obtained Zeolite imidazole framework material;

[0040] Step (2), dissolving cobalt nitrate in water to prepare a precursor solution; impregnating the zeolite imidazole framework material prepared in step (1) in the precursor solution, stirring overnight, then drying, and roasting at 50...

Embodiment 1

[0046] Take a certain amount of cobalt nitrate and dissolve it in water and mark it as A solution, take a certain amount of dimethylimidazole and triethylamine and dissolve it in water and mark it as B solution, and A solution and B solution are uniformly mixed, wherein the mixed solution Cobalt nitrate, dimethylimidazole, triethylamine, water mass ratio = 1:2.3:2.5:69.7, stirred at room temperature for 24 hours; centrifuged, washed; the obtained precipitate was dried to obtain the zeolite imidazole framework material;

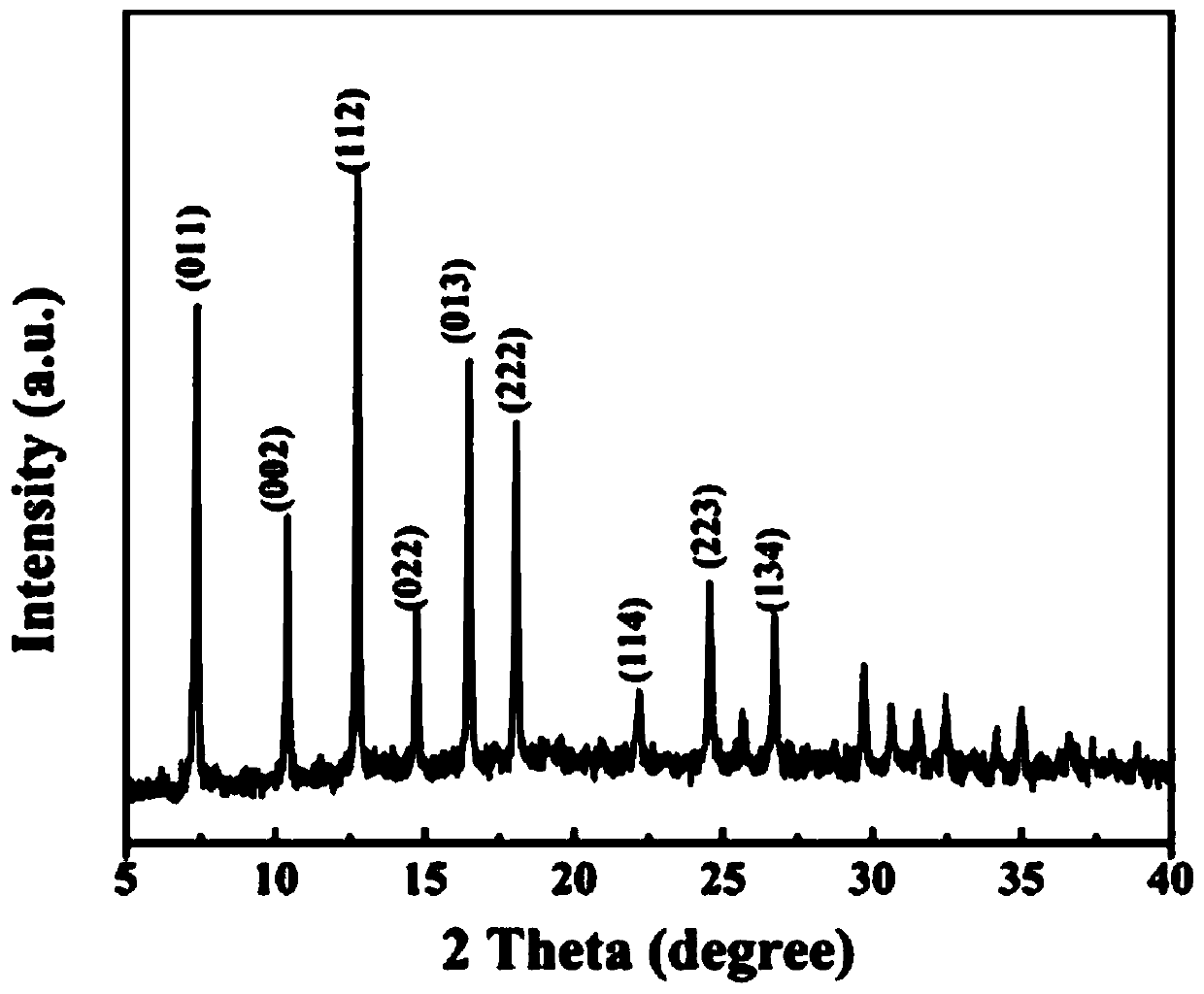

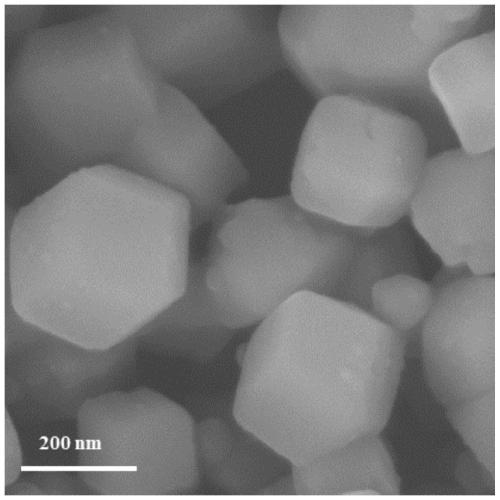

[0047] figure 1 According to the XRD pattern of the prepared zeolite imidazole framework material, it can be confirmed that the zeolite imidazole framework material has been synthesized. figure 2 From the SEM image of the prepared zeolite imidazole framework material, it can be seen that the surface of the prepared material is relatively smooth, polyhedral, and uniform in size, with an average size of about 300 nm.

Embodiment 2

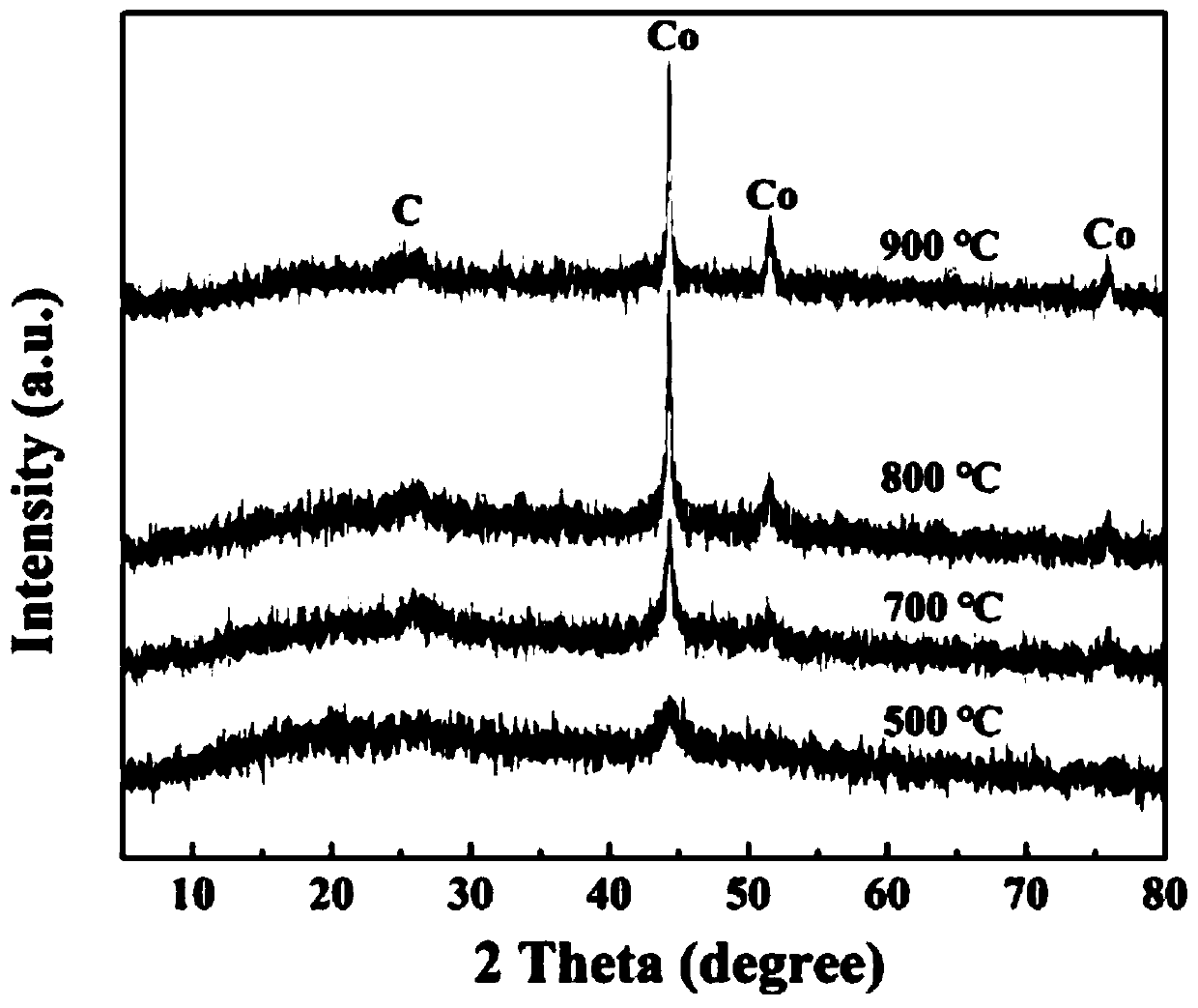

[0049] The zeolite imidazole framework material prepared in Example 1 was placed in a tube furnace and calcined at 500°C, 700°C, 800°C, and 900°C respectively at a heating rate of 5°C / min for 3 hours to obtain Co-Co x o y / CN material. It is used in cyclohexane oxidation reaction, the activity data is listed in Table 1, it can be seen that the material performance is the best when calcined at 900°C, so 900°C is the best calcining temperature. image 3 Co-Co obtained as a zeolite imidazole framework material at different calcination temperatures x o y / CN XRD pattern, it can be seen that the existence of metal Co in Co-Co x o y / CN material. No Co x o y The corresponding diffraction peaks, which may be due to the Co x o y The high degree of dispersion may be due to its amorphous structure. Figure 4 For the prepared Co / Co x o y / NC material SEM image, it can be seen that the prepared Co / Co x o y The / NC material is in the shape of a sea urchin, with a size of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com