Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled aggregate, applied in the field of concrete, can solve problems such as poor compressive strength, achieve good wear resistance, not easy to crack, and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

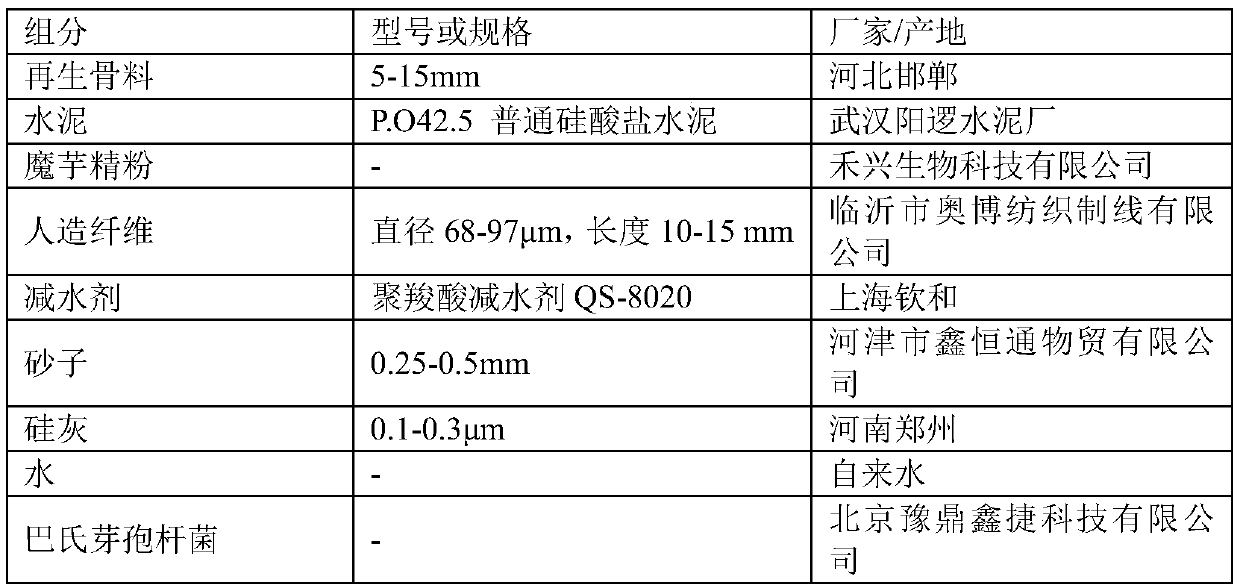

Method used

Image

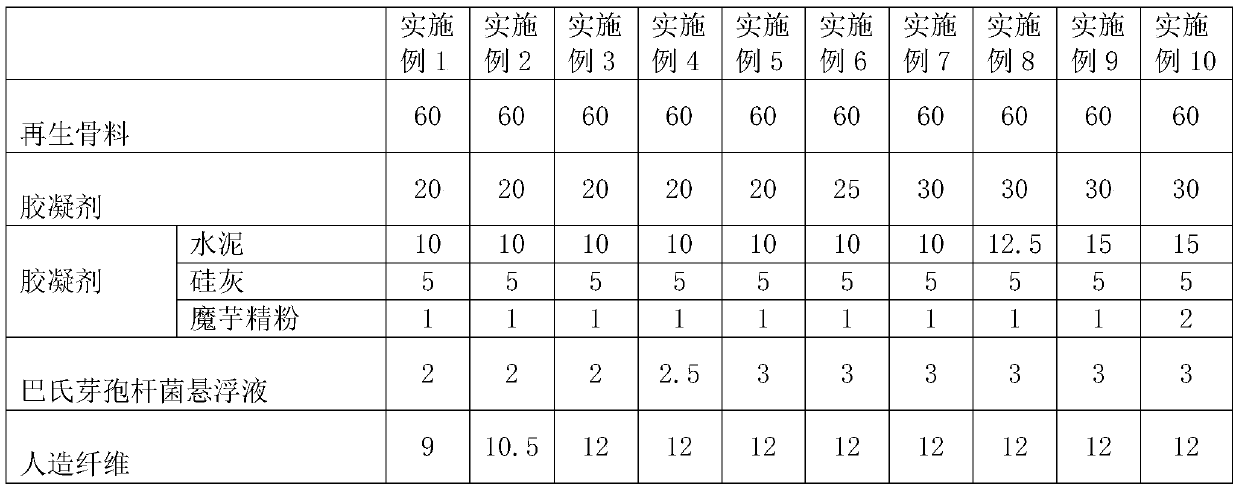

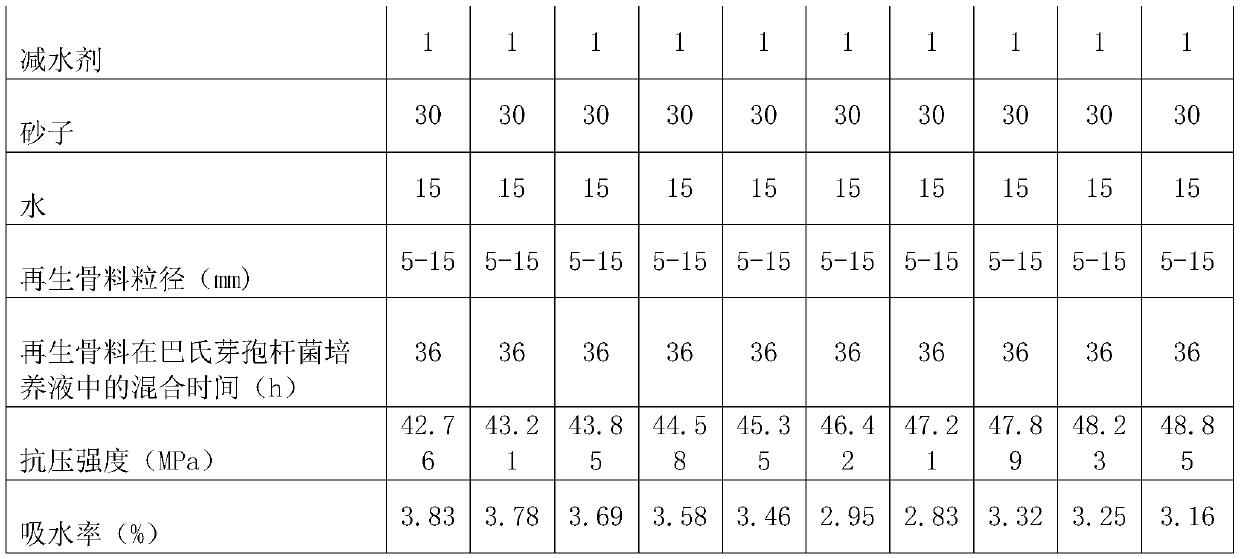

Examples

Embodiment 1

[0035] S1: Mechanically crush and activate the recycled aggregate, and screen out the aggregate with a particle size of 5-15mm;

[0036] S2: remove the dust on the surface of the aggregate obtained in S1 by air blowing;

[0037] S3: Prepare Bacillus pasteurian culture medium, add 5g of yeast powder, 5g of trimethylglycine, 10g of tryptone, 5g of ammonium sulfate, 2g of glutamic acid, and 10g of urea into 1L of ultrapure water, and adjust the pH with 2mol / L NaOH solution When the value reaches 9.0-10, sterilize at 121°C for 30 minutes and cool to room temperature, then inoculate Bacillus pasteurii, and cultivate at 30-35°C, 130-135r / min at a constant temperature for 24 hours, to obtain the Bacillus pasteurian bacteria liquid;

[0038] S4: Dilute the Bacillus pasteurian bacteria liquid obtained in S3 to 4-6×10 with distilled water 6 Individual / mL and take 2 parts by weight;

[0039] S5: At 30-35°C, add 60 parts of recycled aggregate, 1 part of urea, 1 part of calcium nitrate, ...

Embodiment 2

[0043] S1: Mechanically crush and activate the recycled aggregate, and screen out the aggregate with a particle size of 5-15mm;

[0044] S2: remove the dust on the surface of the aggregate obtained in S1 by air blowing;

[0045]S3: Prepare Bacillus pasteurian culture medium, add 5g of yeast powder, 5g of trimethylglycine, 10g of tryptone, 5g of ammonium sulfate, 2g of glutamic acid, and 10g of urea into 1L of ultrapure water, and adjust the pH with 2mol / L NaOH solution When the value reaches 9.0-10, sterilize at 121°C for 30 minutes and cool to room temperature, then inoculate Bacillus pasteurii, and cultivate at 30-35°C, 130-135r / min at a constant temperature for 24 hours, to obtain the Bacillus pasteurian bacteria liquid;

[0046] S4: Dilute the Bacillus pasteurian bacteria liquid obtained in S3 to 4-6×10 with distilled water 6 Individual / mL and take 2 parts by weight;

[0047] S5: At 30-35°C, add 60 parts of recycled aggregate, 1 part of urea, 1 part of calcium nitrate, 1...

Embodiment 3

[0051] S1: Mechanically crush and activate the recycled aggregate, and screen out the aggregate with a particle size of 5-15mm;

[0052] S2: remove the dust on the surface of the aggregate obtained in S1 by air blowing;

[0053] S3: Prepare Bacillus pasteurian culture medium, add 5g of yeast powder, 5g of trimethylglycine, 10g of tryptone, 5g of ammonium sulfate, 2g of glutamic acid, and 10g of urea into 1L of ultrapure water, and adjust the pH with 2mol / L NaOH solution When the value reaches 9.0-10, sterilize at 121°C for 30 minutes and cool to room temperature, then inoculate Bacillus pasteurii, and cultivate at 30-35°C, 130-135r / min at a constant temperature for 24 hours, to obtain the Bacillus pasteurian bacteria liquid;

[0054] S4: Dilute the Bacillus pasteurian bacteria liquid obtained in S3 to 4-6×10 with distilled water 6 Individual / mL and take 2 parts by weight;

[0055] S5: At 30-35°C, add 60 parts of recycled aggregate, 1 part of urea, 1 part of calcium nitrate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com