Water-based gas-phase antirust concentrated solution and preparing and using methods thereof

A gas-phase anti-rust and concentrated liquid technology, which is applied in the field of water-based gas-phase anti-rust concentrated liquid, can solve the problems of surface defects of metal products and precision metal products, affect the surface quality and precision, and have no gas-phase anti-rust performance, and achieve excellent contact Anti-rust ability, easy to clean, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of rosin acid amide compound antirust agent:

[0026] Accurately weigh 28 grams of purified abietic acid and add it to a four-necked flask filled with nitrogen, add 0.05 grams of catalyst PB, heat to 140°C under nitrogen atmosphere, and slowly add 14 grams of maleic anhydride in batches under stirring In order to ensure that there is no white mist overflowing from the mouth of the reaction bottle, the temperature was raised to 190°C, and the temperature was kept for 3 hours; the temperature of the reaction solution was lowered to 150°C, and 18 grams of diethanolamine, 1.5 grams of KOH, and 18 grams of diethanolamine were slowly added in batches, and the temperature was raised to React at 180°C for 3 hours, slowly add 4 grams of diethanolamine for amination reaction for 0.5 hours, naturally cool down to below 100°C, add 25 grams of deionized water, and obtain rosin acid amide compound rust inhibitor 1.

[0027] Accurately weigh 34 grams of purified abietic ac...

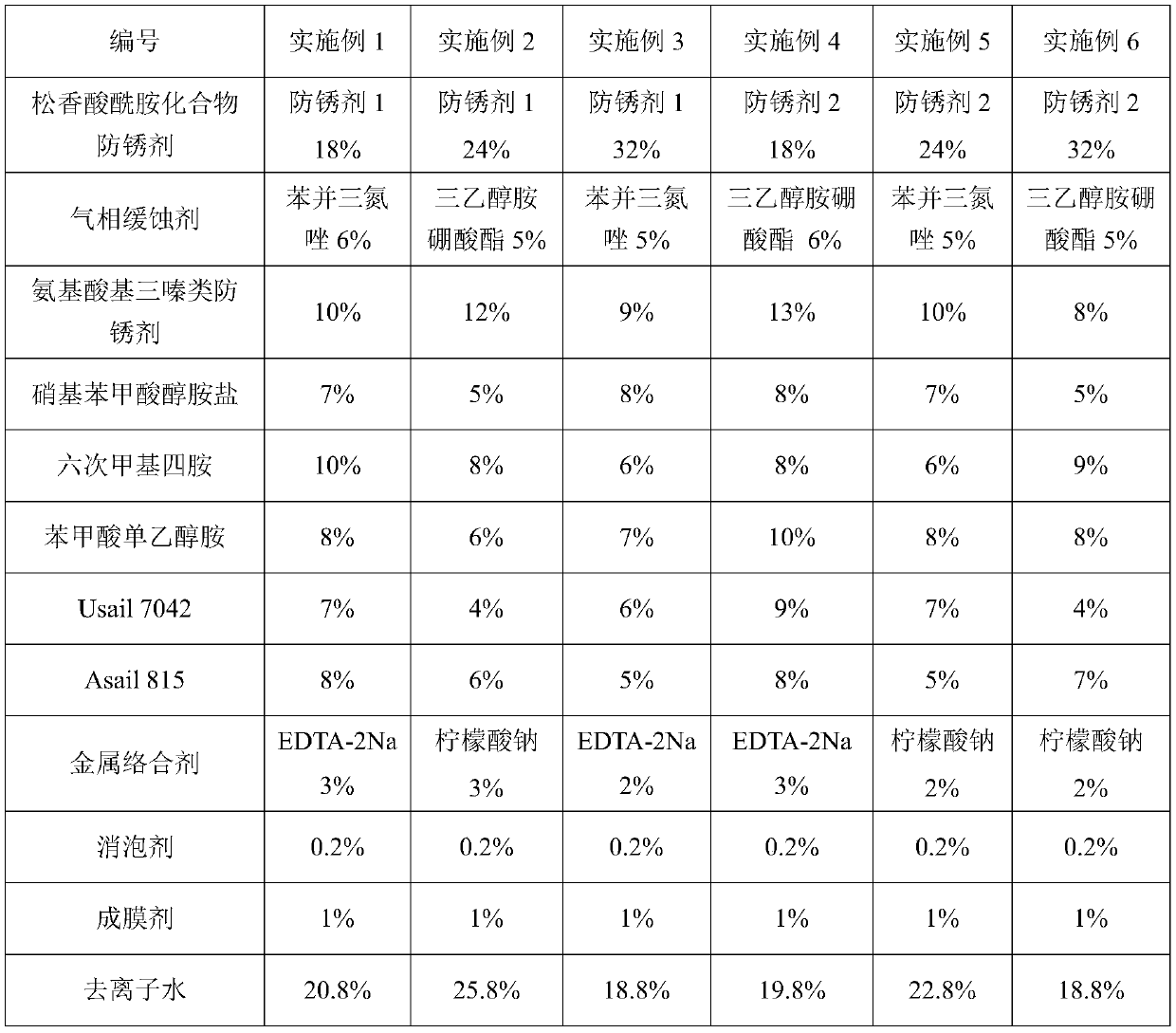

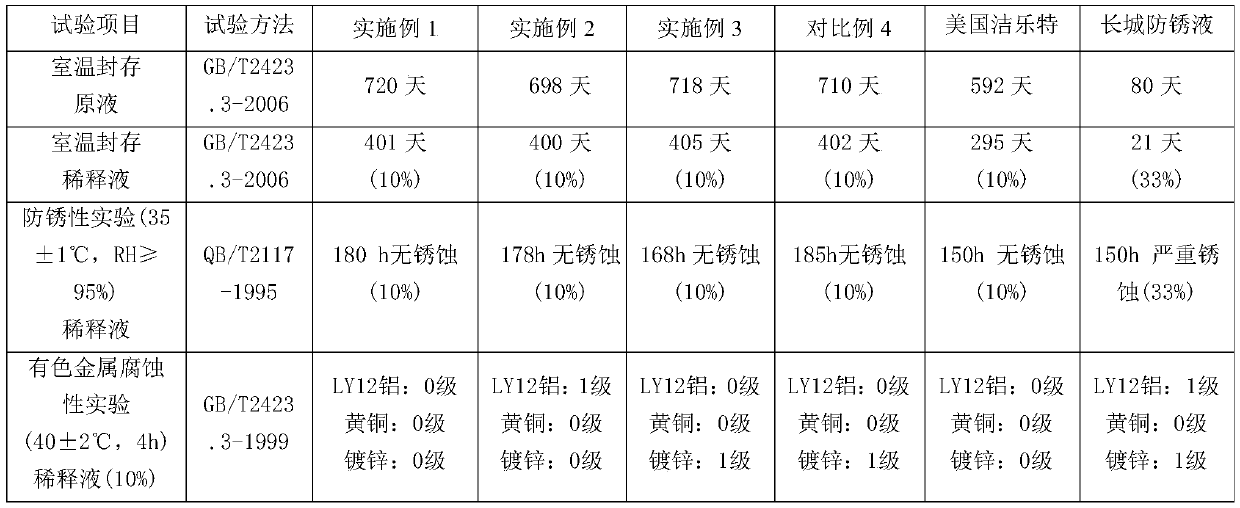

Embodiment 1-6

[0029]

[0030]The preparation method of the water-based vapor-phase antirust concentrate listed in the examples in the table above comprises the following steps: adding water accounting for 80% of the total water into the reactor and heating it to 50-60°C; adding nitrobenzene according to the ratio Alcohol amine salt of formic acid to make it completely dissolved, add abietic acid amide compound antirust agent, hexamethylenetetramine, benzoic acid monoethanolamine in sequence according to the proportion to dissolve completely, and then add amino acid triazine antirust agent in sequence according to the proportion , gas-phase corrosion inhibitor, special water-based rust inhibitor, keep the solution at 50-60°C to dissolve it completely; add 20% of the total water, keep the solution at 50-60°C and stir for 2 hours, and then follow the stated ratio Add metal complexing agent, defoamer, and film-forming agent, continue to stir for 30 minutes, and cool down to room temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com