Preparation process of modified water-resistant fibers

A preparation process and fiber technology, applied in the field of preparation technology of modified water-resistant fibers, can solve the problems of respiratory irritation, operation mode limitation, inducing bronchial asthma, etc., and achieve the effect of good breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

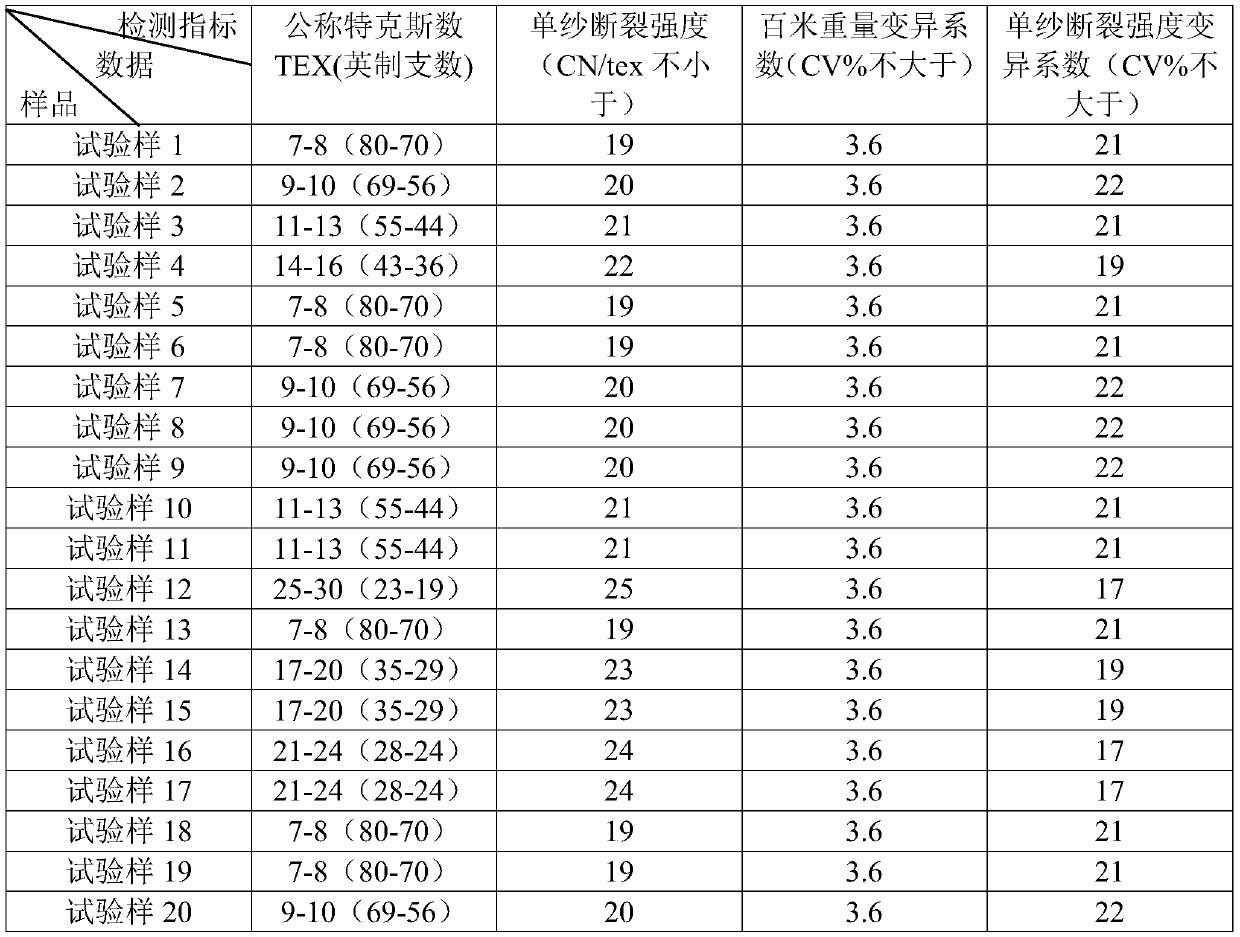

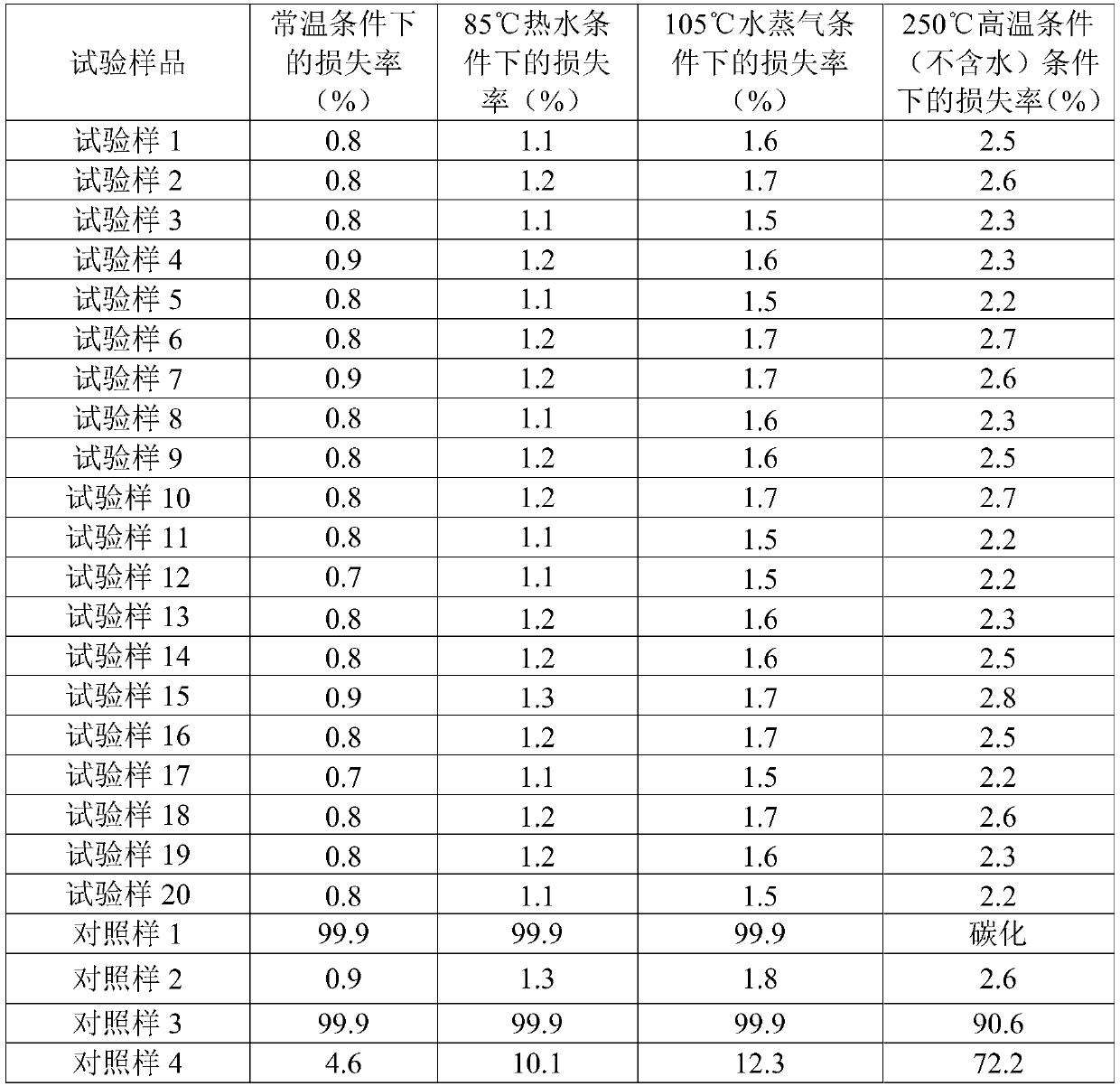

Examples

Embodiment 1

[0046] Embodiment 1: A kind of preparation technology of modified water-resistant fiber, comprises following operation steps:

[0047] Step 1, fully mixing the hexamethylolmelamine and cosolvent to form the first mixture;

[0048] Mix polyvinyl alcohol and water, heat up to 80°C to completely dissolve polyvinyl alcohol, and form a second mixture with a mass concentration of 16%; fully mix mirabilite, alkali, and water, wherein sodium sulfate accounts for 100% by mass of the third mixture The component content is respectively 30%, and the pH value of adding alkali to the third mixture is 7.5-11;

[0049] Step 2, fully mix the first mixture and the second mixture, keep warm at 80°C, adjust the pH value to 1.5-1.8 with acid, and obtain the spinning dope;

[0050] Step 3: Spinning the spinning dope, and the jetted fibers enter the third mixture with a temperature of 25°C for coagulation bath treatment, and the coagulation bath treatment time for each meter of jetted fibers is 0.2...

Embodiment 2-4

[0054] Example 2-4: A preparation process for modified water-resistant fibers, the difference from Example 1 is that sodium sulfate accounts for 32%, 35%, and 40% of the mass percentage of the third mixture, and alkali is added to The pH of the third mixture is 7.5-11. And the alkali in the spinning dope in embodiment 2-4 is sodium bicarbonate.

Embodiment 5

[0055] Example 5: A preparation process for modified water-resistant fibers, the difference from Example 1 is that in the first mixture in step 1, the mass percentage of hexamethylolmelamine is 10%, and the proportion of cosolvent The mass percent composition is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com