Continuous carbon fiber reinforced polyaryletherketone composite prepreg tape and preparation method thereof

A composite material, phenolphthalein polyaryletherketone technology, applied in the field of continuous fiber reinforced phenolphthalein polyaryletherketone composite material prepreg tape and its preparation, can solve the problems of poor process stability, high maintenance cost, and easy moisture absorption of solvents, etc., to achieve Excellent mechanical and thermal properties, reduced production costs, and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve 6kg of phenolphthalein polyaryl ether ketone resin in acetophenone, pour a solution with a mass concentration of 30% into the dipping tank, and immerse 12kg of Toray T700-12K carbon fiber through the tank with a traction rate of 0.6m / min , Through a mixed solution of acetone and toluene (the volume ratio of acetone to toluene is 4:1), the resin is melted by a hot drying tunnel at 220°C / 15min+350°C / 15min, and the resin is compacted under a pressure of 5MPa at 330°C. Dip tape, the fiber volume fraction is 60%. The flexural strength of the composite material prepared by the molding process of the prepreg tape is 1850MPa, and the interlayer shear strength is 105MPa.

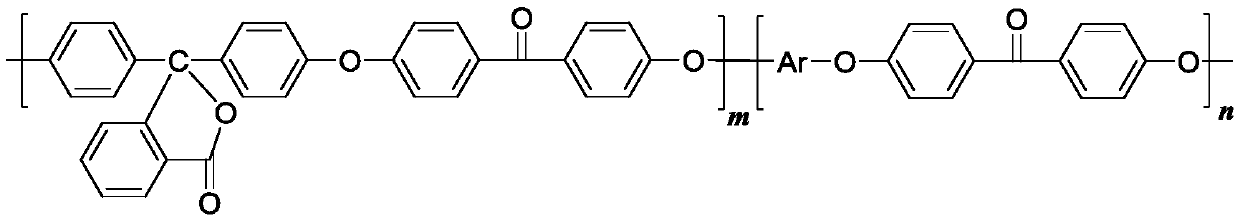

[0022] The structure of the phenolphthalein polyaryl ether ketone resin is as follows: m=0.7, n=0.3

[0023]

Embodiment 2

[0025] Dissolve 3kg of phenolphthalein polyaryl ether ketone resin in benzyl alcohol, and pour a solution with a mass concentration of 15% into the dipping tank, and then impregnate 10kg of CCF700S-12K carbon fiber through the dipping tank at a traction rate of 0.3m / min. The solution is heated in a drying tunnel at 220°C / 40min+360°C / 20min to melt the resin, and compacted by a 350°C hot press roll under a pressure of 10MPa to obtain a prepreg tape with a fiber volume fraction of 75%. The flexural strength of the composite material prepared by the molding process of the prepreg tape is 1923MPa, and the interlayer shear strength is 112MPa.

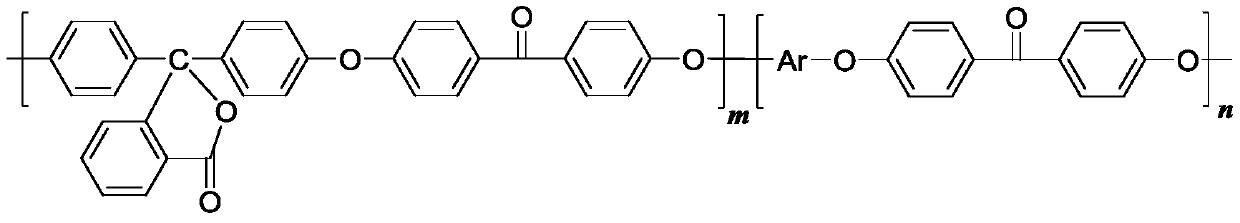

[0026] The structure of the phenolphthalein polyaryl ether ketone resin is as follows: m=0.8, n=0.2

[0027]

Embodiment 3

[0029] Dissolve 4 kg of phenolphthalein polyaryl ether ketone resin in cyclohexanone, pour a solution with a mass concentration of 20% into the dipping tank, and immerse 11 kg of Toray T800-6K carbon fiber through the tank with a traction rate of 0.4m / min , Through a mixed solution of ethanol and xylene (the volume ratio of ethanol and xylene is 8:2), the resin is melted by a hot drying tunnel at 200℃ / 30min+380℃ / 15min, and the resin is compacted by a 360℃ hot press roll under 3MPa pressure The fiber volume fraction of prepreg tape is 70%. The flexural strength of the composite material prepared by the molding process of the prepreg tape is 1872MPa, and the interlayer shear strength is 110MPa.

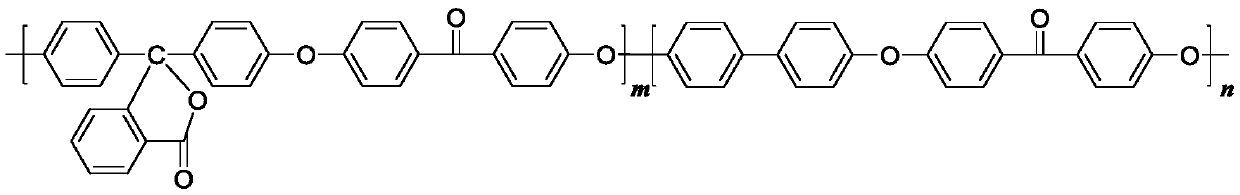

[0030] The structure of the phenolphthalein polyaryl ether ketone resin is as follows: m=0.5, n=0.5

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com