Aromatic single-component polyurea coating and preparation method thereof

A one-component, aromatic technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited hydrolysis resistance, unsatisfactory use, short service life, etc., to achieve excellent hydrolysis resistance, good environmental protection, Excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The application also provides a preparation method for the aromatic single-component polyurea coating, comprising the following steps:

[0035] A) According to the composition ratio, heat the polycarbonate diol, dimer acid polyester diol and hydroxyl-terminated liquid rubber in a vacuum to remove water and then add isocyanate to react;

[0036] B) Mix and heat the reaction product obtained in step A) with an adhesion promoter and an imine latent curing agent, then add an environmentally friendly diluent to cool down, and then add a catalyst and a defoamer to obtain an aromatic one-component polyurea coating.

[0037] In the preparation process of the above-mentioned aromatic single-component polyurea coating, in step A), the heating temperature is 110-120°C, the temperature for adding isocyanate is 60-65°C, and the reaction temperature is 80-120°C. 90°C for 2-3 hours; in step B), the heating temperature is 80-85°C, and the cooling temperature is 60-65°C.

[0038]The po...

Embodiment 1

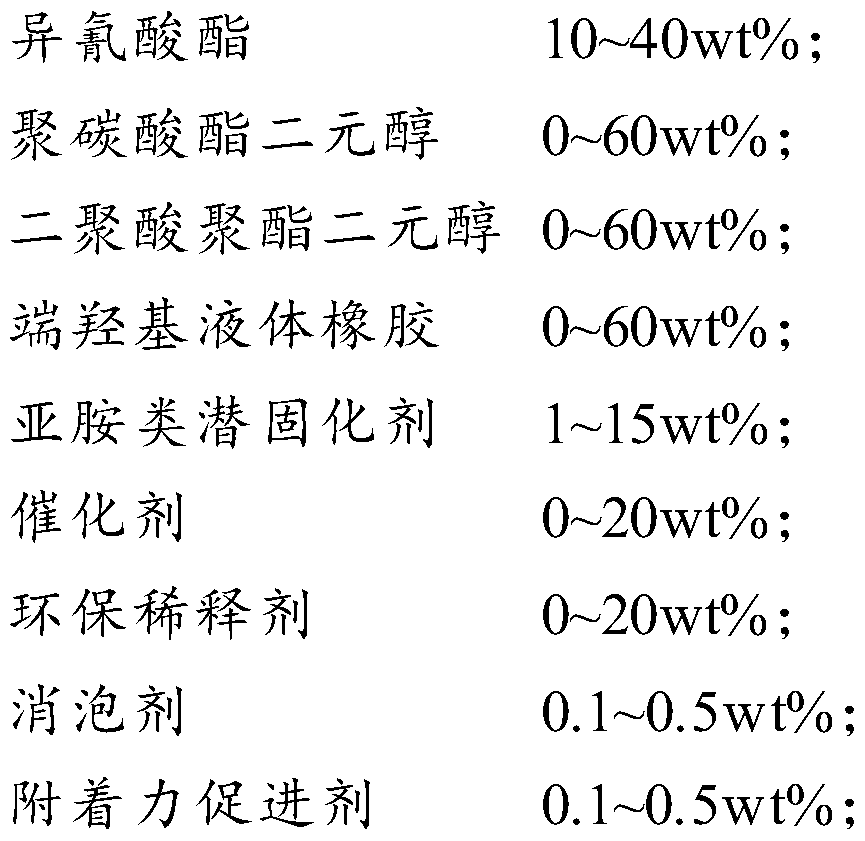

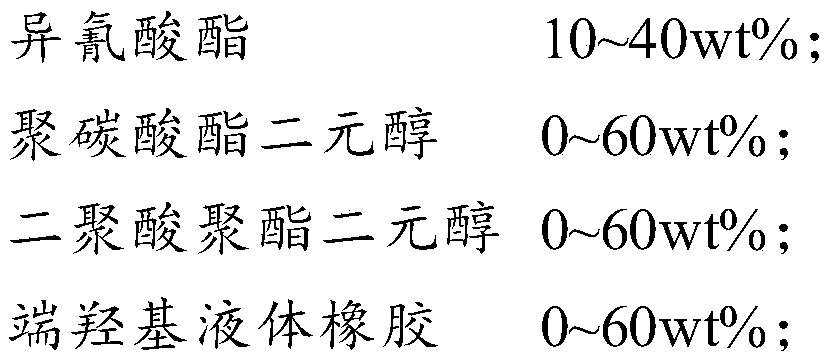

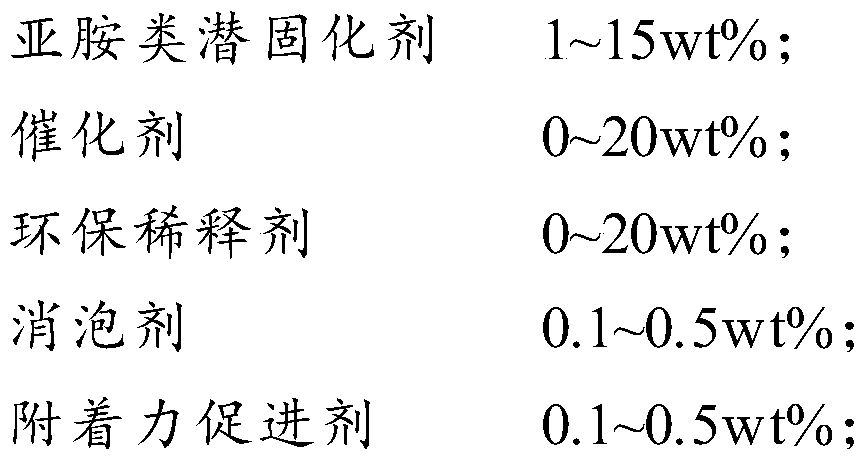

[0041] An aromatic single-component polyurea coating, comprising the following components in mass fraction: 25% MDI, 50% polycarbonate diol 2000, 15% imine latent curing agent, 0.1% catalyst, 9.4% environmental protection dilution agent, 0.2% 3-isocyanatopropyl triethoxysilane, 0.3% defoamer.

[0042] Preparation method: 1) Put polycarbonate diol into a three-necked flask, heat to 110-120°C to remove moisture in a vacuum, cool to 60-65°C, add corresponding isocyanate, react at 80-90°C for 2 hours, then cool down to 65-70°C;

[0043] 2) Drop in the adhesion promoter and imine latent curing agent through the dropping device, and keep the reaction temperature balanced by setting the dropping speed. After the addition, keep it at 80-85°C for half an hour, add the environmentally friendly diluent and cool down by 60-65°C , add the corresponding defoamer, catalyst and stir for 15 minutes before discharging.

Embodiment 2

[0045] An aromatic single-component polyurea coating, comprising the following components in mass fraction: 20% TDI, 50% polycarbonate diol 2000, 12% imine latent curing agent, 0.1% catalyst, 0.2% 3- Isocyanatopropyltrimethoxysilane, 17.4% environmentally friendly thinner, 0.3% defoamer.

[0046] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com