Trivalent black chromium electroplating solution for solar heat collector

A solar collector and electroplating solution technology, applied in the field of electroplating, can solve the problems of poor bonding performance of trivalent chromium electroplating coating and substrate, affecting the corrosion resistance of metal layer, and easy cracking of the coating, and achieving excellent spectral selection. performance, improve coverage, and improve binding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

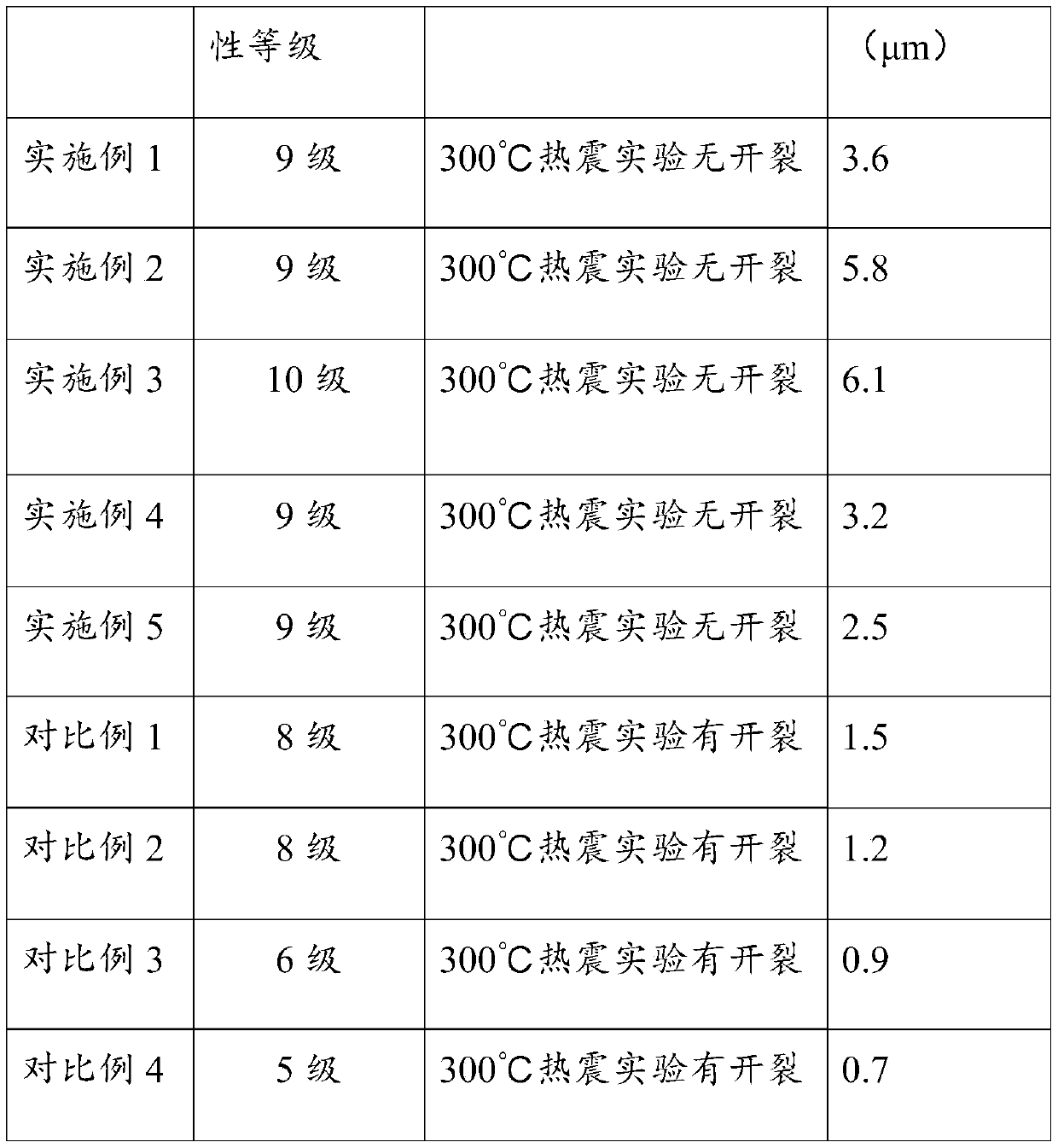

Examples

Embodiment 1

[0022] The trivalent black chromium electroplating solution for the solar heat collector described in the embodiment of the present invention is composed as follows: 10g / L chromium sulfate hexahydrate, 10g / L chromium potassium sulfate, 50g / L sodium sulfate, 50g / L ammonium sulfate, 50g / L sulfuric acid Potassium, 54g / L boric acid, 6g / L sodium citrate, 5g / L citric acid, 25g / L salicylic acid, cysteine 2g / L, potassium thiocyanate 1g / L, 0.1g / L succinic acid di Sodium isooctyl sulfonate, 0.1 g / L PEG600, and the above-mentioned components of the embodiment of the present invention are uniformly mixed, and water is added to obtain an electroplating solution.

Embodiment 2

[0024] The trivalent black chromium electroplating solution for the solar heat collector described in the embodiment of the present invention is composed as follows: 25g / L chromium sulfate hexahydrate, 10g / L chromium potassium sulfate, 100g / L sodium sulfate, 80g / L ammonium sulfate, 63g / L boric acid , 7g / L sodium citrate, 15g / L citric acid, 35g / L salicylic acid, cysteine 3g / L, potassium thiocyanate 1g / L, 0.25g / L diisooctyl sodium sulfosuccinate , 0.25g / LPEG200, mix the above-mentioned components of the embodiment of the present invention evenly, add water, and obtain the electroplating solution.

Embodiment 3

[0026] The trivalent black chromium electroplating solution for the solar heat collector described in the embodiment of the present invention is composed as follows: 35g / L chromium sulfate hexahydrate, 10g / L chromium potassium sulfate, 80g / L sodium sulfate, 50g / L ammonium sulfate, 50g / L sulfuric acid Potassium, 77.3g / L boric acid, 7.7g / L sodium citrate, 20g / L citric acid, 30g / L salicylic acid, cysteine 3.5g / L, potassium thiocyanate 1.5g / L, 0.9g / L L diisooctyl sodium sulfosuccinate, 0.6g / L PEG600, mix the above-mentioned components of the embodiment of the present invention evenly, add water, and obtain the electroplating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com