A method for preparing a diamond vortex beam generator by chemical treatment-assisted laser processing and its application

A chemical treatment and vortex beam technology, applied in chemical instruments and methods, liquid cleaning methods, laser welding equipment, etc., can solve the problems of complex preparation process, high cost, poor precision, etc. The effect of low cost and good optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

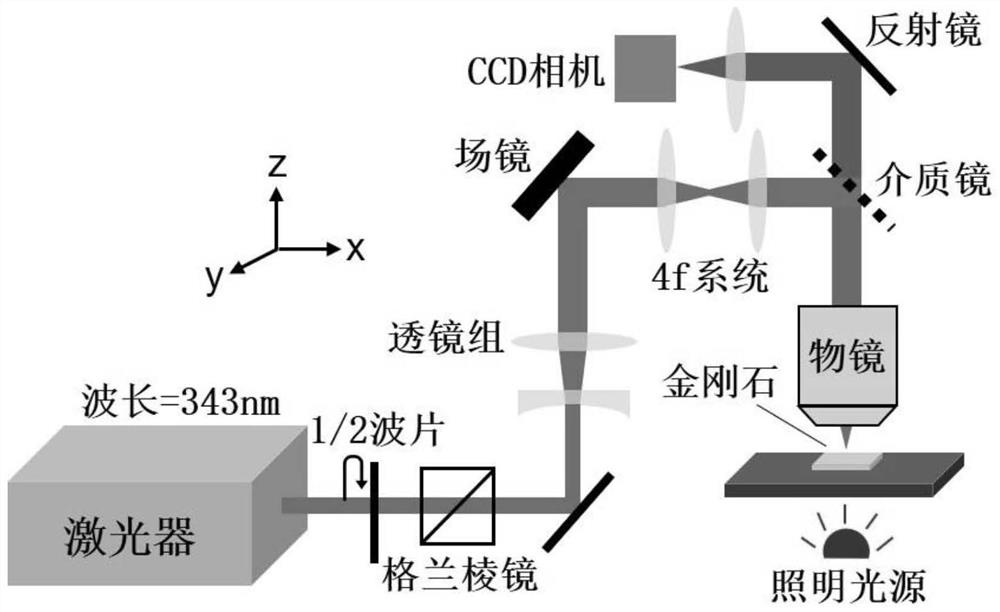

[0033] Fabrication of diamond vortex beam generators by chemical treatment-assisted laser processing.

[0034] After using the ultraviolet femtosecond laser to directly write the designed spiral zone plate structure on the diamond surface, put the diamond sample into the prepared mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, and heat it in a hydrothermal reaction oven. The chemical treatment process After the end, the diamond sample is taken out and cleaned, and finally the vortex beam generator on the diamond surface is obtained.

[0035] A method for preparing a diamond vortex beam generator by chemical treatment-assisted laser processing, the specific steps are as follows:

[0036] (1) Preparation of diamond samples: The diameter of the purchased high-temperature and high-pressure diamond samples is about 1 mm, the upper and lower surfaces are polished, and the thickness is 800 μm; first, put the diamond particles to be processed by laser i...

Embodiment 2

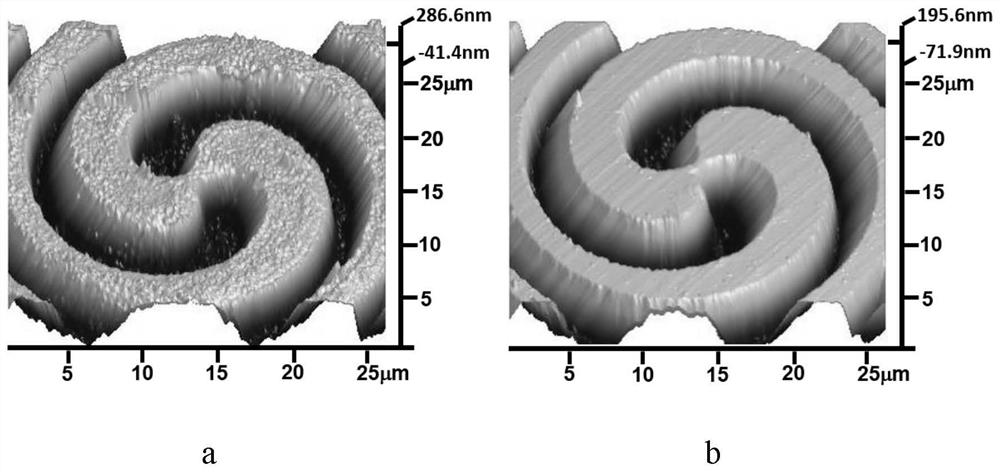

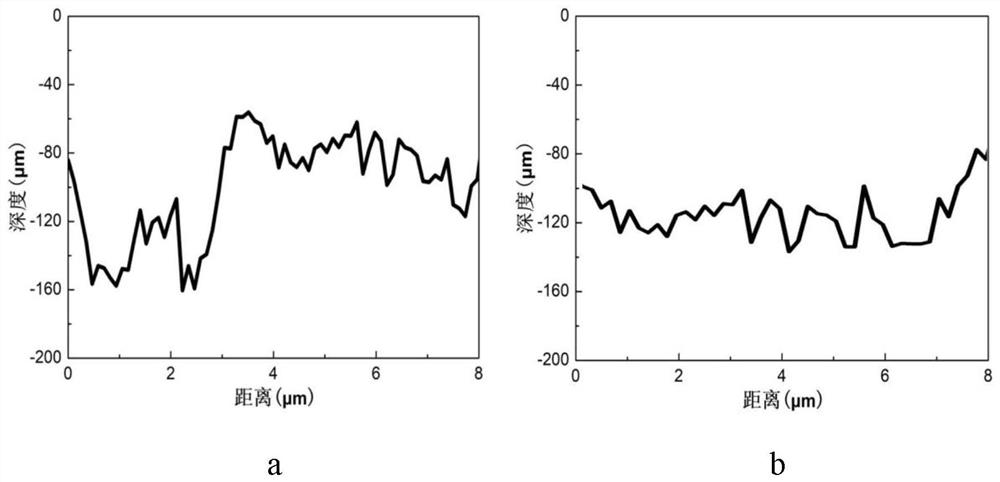

[0043] The diamond-based vortex beam generator is applied to the generation of vortex beams and optical imaging focusing.

[0044] The device size, topological charge, focal length, etc. of the diamond vortex beam generator prepared by chemical treatment-assisted laser processing can be designed. The preparation process is simple, time-consuming, and has no mask. It can be applied to vortex beams. generation and optical imaging focusing. The spiral zone plate structure designed as a vortex beam generator can be regarded as a combination of a common amplitude Fresnel zone plate and a spiral phase plate, so the Gaussian beam after passing through the spiral zone plate structure The amplitude and phase change, and the changed phase is proportional to the azimuth angle, carrying the orbital angular momentum, the Gaussian beam becomes a vortex beam, and the spiral zone plate structure also retains the imaging focus of the Fresnel zone plate similar to a convex lens Features. Ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com