A kind of preparation method of silver-copper composite electrode

A composite electrode, silver-copper technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the difficulty of interface microstructure control, interface structure control, process control, etc. problem, achieve the effect of reducing defect size and quantity, high reliability, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

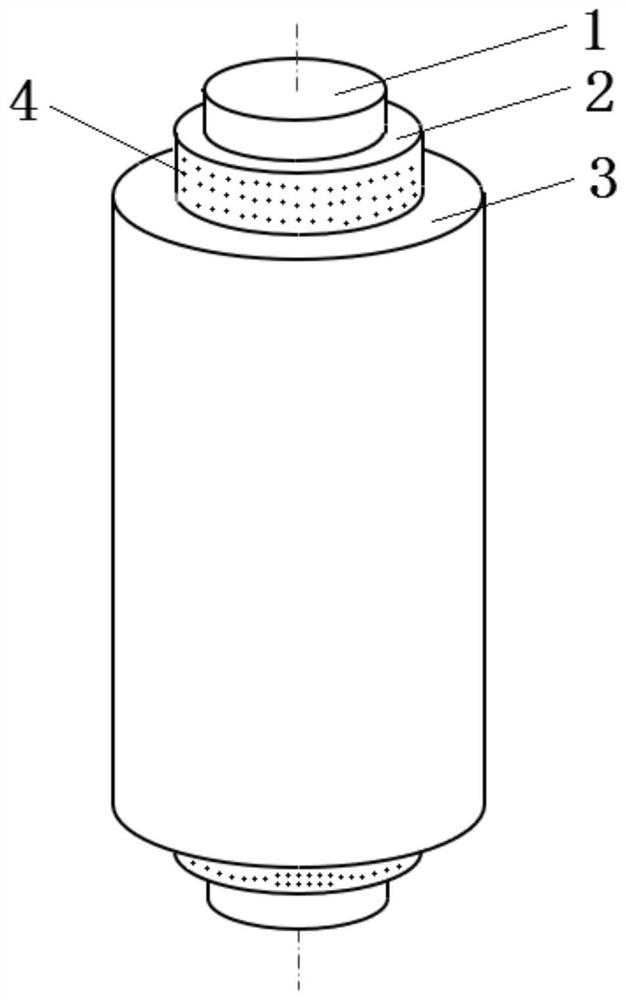

[0032] This embodiment includes the following steps:

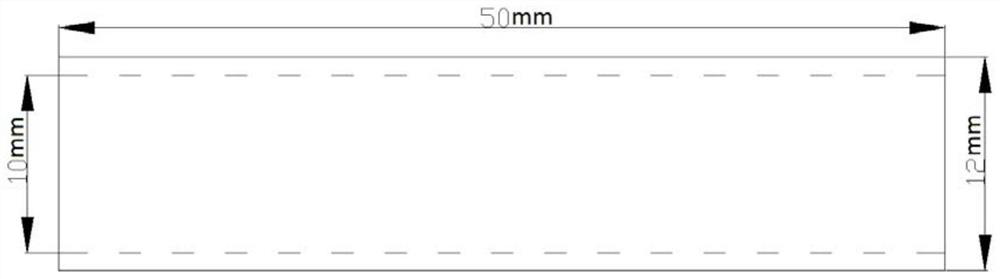

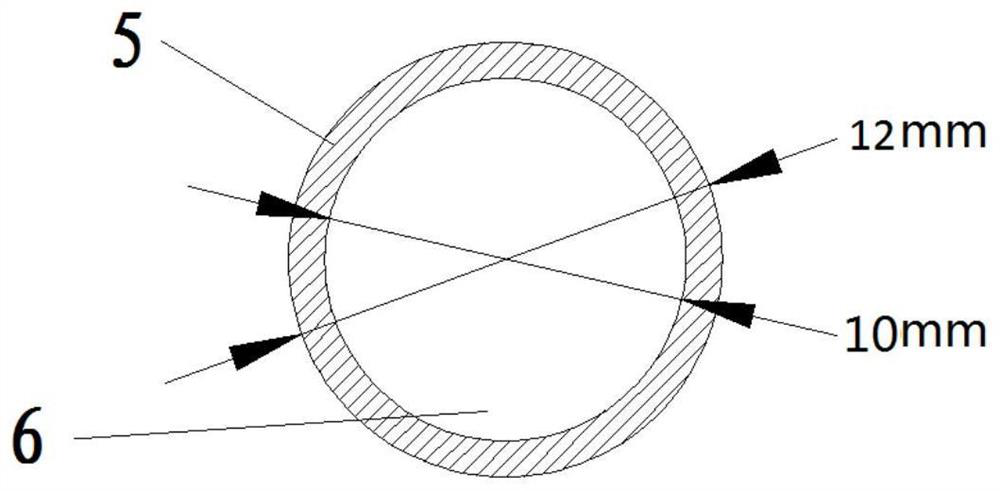

[0033] Step 1. Put the surface of the 10mm×70mm (diameter×length) oxygen-free copper rod whose grade is TU1 and the silver tube whose grade is IC-Ag99.99 of 11.99mm×9.99mm×65mm (outer diameter×inner diameter×length) The inner wall of the inner wall is polished, and the polished copper rod and the silver tube are cleaned, and then the copper rod is inserted into the silver tube by a hydraulic press to obtain a silver-copper rod; the cleaning process is: adopt mechanical processing Remove the oxide layer and other foreign pollutants covered on the surface of copper rods and silver tubes, and then use ethanol to degrease the surface of copper rods and silver tubes;

[0034] Step 2: Clean the 35CrMo steel pipe with a size of 32.04mm×12.04mm×60mm (outer diameter×inner diameter×length), and then evenly spray the side surface of the silver tube in the silver-copper rod obtained in step 1 with a release agent to suspend it liquid...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1. Put the surface of the 30mm×120mm (diameter×length) oxygen-free copper rod with the grade of TU2 and the silver tube with the grade of 35.80mm×29.80mm×115mm (outer diameter×inner diameter×length) with the grade of IC-Ag99.95 The inner wall of the inner wall is polished, and the polished copper rod and the silver tube are cleaned, and then the copper rod is inserted into the silver tube by a hydraulic press to obtain a silver-copper rod; the cleaning process is: adopt mechanical processing Remove the oxide layer and other foreign pollutants covered on the surface of copper rods and silver tubes, and then use acetone to degrease the surface of copper rods and silver tubes;

[0043] Step 2: Clean the 96.17mm×36.17mm×110mm (outer diameter×inner diameter×length) steel pipe of grade 35CrMo, and then evenly spray the side surface of the silver tube in the silver-copper rod obtained in step 1 with a release agent fo...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Step 1. Put the surface of the pure copper rod whose grade is T2 of 40mm×170mm (diameter×length) and the silver tube whose grade is IC-Ag99.90 of 47.50mm×39.50mm×165mm (outer diameter×inner diameter×length). The inner wall is polished, and the polished copper rod and silver tube are cleaned, and then the copper rod is inserted into the silver tube by a hydraulic press to obtain a silver-copper rod; the cleaning process is: use mechanical processing to remove The oxide layer and other foreign pollutants covered on the surface of copper rods and silver tubes, and then use acetone to degrease the surface of copper rods and silver tubes;

[0050] Step 2. Clean the 30CrMnSiA steel pipe with the size of 148.10mm×48.10mm×160mm (outer diameter×inner diameter×length), and then evenly spray the side surface of the silver tube in the silver-copper rod obtained in step 1 with a release agent to suspend it liquid and dried, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com