Preparation method of polyether sulfone short fibers

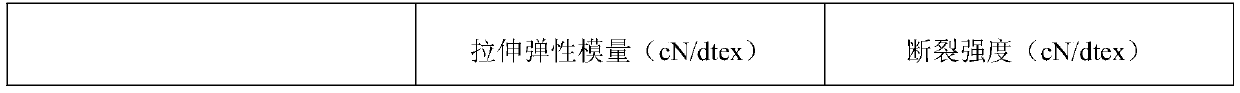

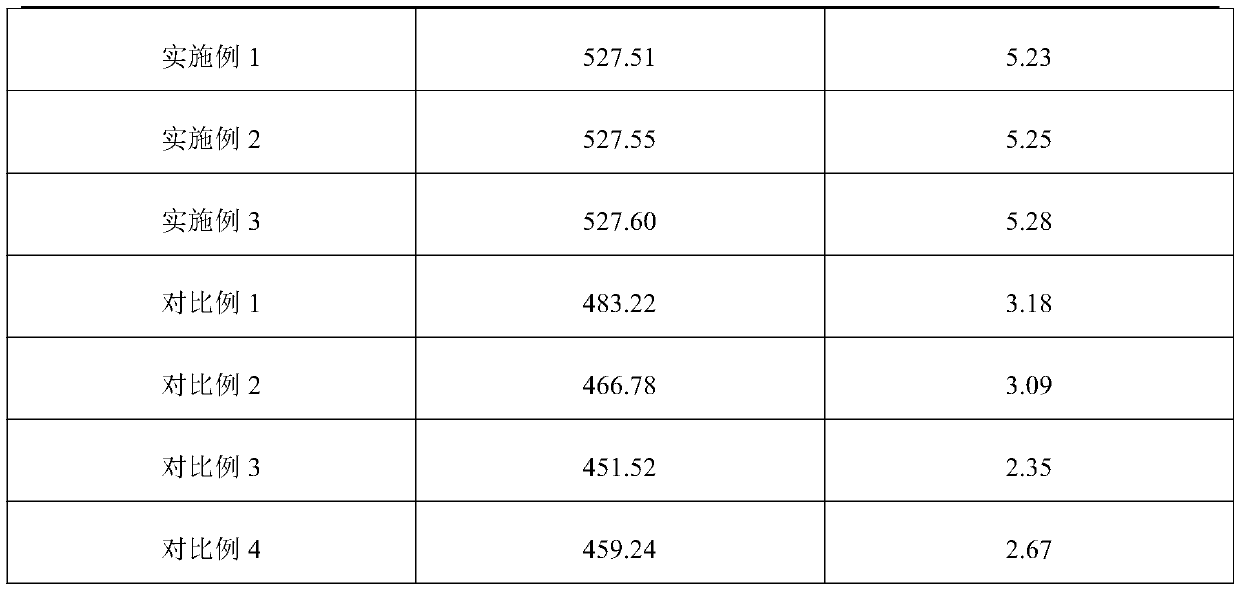

The technology of polyethersulfone fiber and polyethersulfone is applied in the field of preparation of polyethersulfone short fiber, which can solve the problems of high elongation at break, poor elastic modulus and breaking strength index, low breaking strength of filter material, etc. Achieve the effect of low elongation at break, reduced elongation at break, and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of polyethersulfone staple fiber, polyethersulfone resin is first melt-spun to make polyethersulfone fiber, then cut to make polyethersulfone staple fiber of 10mm; Wherein, by weight, the polyethersulfone The preparation method of sulfone resin is as follows:

[0033] (1) Pour bisphenol S into 8 times the mass concentration of 30% potassium hydroxide aqueous solution, ultrasonic vibration treatment, and centrifugation to obtain pretreated bisphenol S;

[0034] (2) Then, add 1600 parts of diphenyl sulfone into the nitrogen-protected reactor, stir and heat up to 60°C, add 100 parts of pretreated bisphenol S and 280 parts of 4,4'-dichlorodiphenyl sulfone monomer, wait After the monomers are completely dissolved, add 55 parts of potassium hydroxide and 50 parts of toluene, continue to stir and heat up to 170°C, add distilled water drop by drop until all solid insolubles in the system are dissolved, stir for 40 minutes, and then add 135 parts of ...

Embodiment 2

[0050] A kind of preparation method of polyethersulfone staple fiber, polyethersulfone resin is melt-spun to make polyethersulfone fiber first, then cut to make polyethersulfone staple fiber of 15mm; Wherein, by weight part, described polyethersulfone The preparation method of sulfone resin is as follows:

[0051] (1) Pour bisphenol S into a 40% potassium hydroxide aqueous solution with a mass concentration of 5 times the weight, perform ultrasonic vibration treatment, and centrifuge to obtain pretreated bisphenol S;

[0052] (2) Then, add 1500 parts of diphenyl sulfone into the reaction kettle protected by nitrogen, stir and heat up to 70°C, add 80 parts of pretreated bisphenol S and 280 parts of 4,4'-dichlorodiphenyl sulfone monomer, wait After the monomer is completely dissolved, add 58 parts of potassium hydroxide and 40 parts of toluene, continue to stir and heat up to 190°C, add distilled water drop by drop until all solid insolubles in the system are dissolved, stir for...

Embodiment 3

[0068] A kind of preparation method of polyethersulfone short fiber, polyethersulfone resin is melt-spun to make polyethersulfone fiber first, cut and make the polyethersulfone short fiber of 12mm then; Wherein, by weight, described polyether sulfone The preparation method of sulfone resin is as follows:

[0069] (1) Pour bisphenol S into a 35% potassium hydroxide aqueous solution with a mass concentration of 6 times the weight, perform ultrasonic vibration treatment, and centrifuge to obtain pretreated bisphenol S;

[0070] (2) Then, add 1550 parts of diphenyl sulfone into the nitrogen-protected reaction kettle, stir and heat up to 65°C, add 90 parts of pretreated bisphenol S and 280 parts of 4,4'-dichlorodiphenyl sulfone monomer, wait After the monomers are completely dissolved, add 57 parts of potassium hydroxide and 45 parts of toluene, continue to stir and heat up to 180°C, add distilled water drop by drop until all solid insolubles in the system are dissolved, stir for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com