Top-emitting silicon-based perovskite light-emitting diode and preparation method thereof

A technology of light-emitting diodes and perovskites, which is applied in the manufacture of semiconductor/solid-state devices, organic semiconductor devices, electrical components, etc., can solve the problems of insufficient matching of p-type silicon wafer energy bands and inconsistent properties of the hole transport layer, and achieve Effects of lowering the injection barrier and increasing the starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

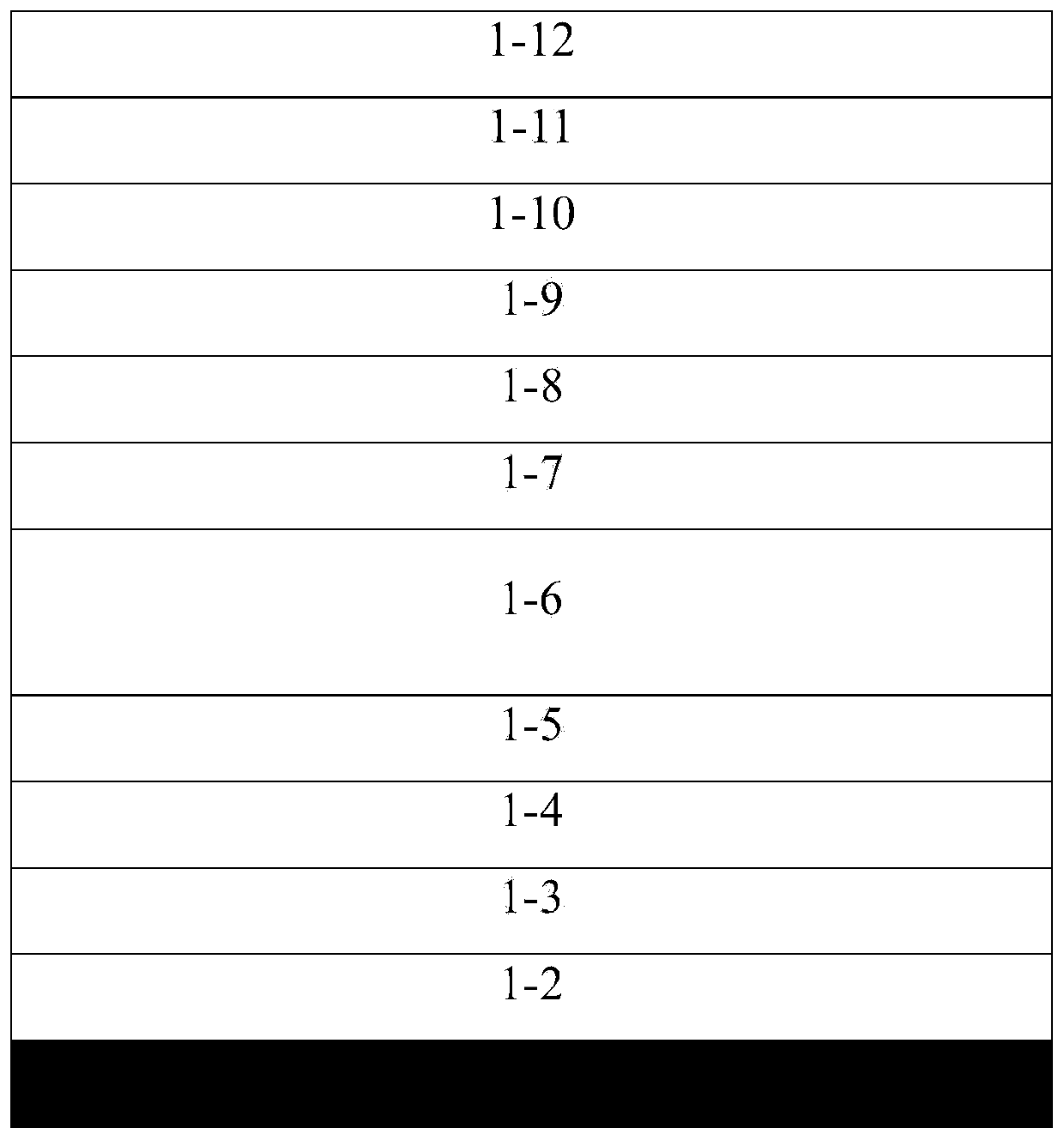

Image

Examples

Embodiment 1

[0042] The preparation method of the top-emitting silicon-based perovskite light-emitting diode provided in this embodiment is as follows:

[0043] a. Use an ultrasonic cleaner to clean and dry the silicon wafer;

[0044] b. Evaporate a layer of Cr metal layer on the surface of the cleaned silicon wafer with a thickness of 30nm and a rate of 0.3A° / s; then evaporate a layer of Au metal layer with a thickness of 50nm and a rate of 0.6A° / s;

[0045] c. Prepare a layer of NiO on the bottom metal electrode by magnetron sputtering x Transition layer with a thickness of 10nm and a rate of 1.0A° / s;

[0046] d. Take 85μl of PEDOT:PSS solution, set the spin coating speed to 2500r / min, time 40s, and anneal at 150℃ for 15min;

[0047] e. Weigh 80.8 mg of phenethyl ammonium bromide, 4.0 mg of methyl ammonium chloride, 50.0 mg of methyl ether ammonium bromide, and 220.2 mg of PbBr 2 Dissolve in 1ml of DMSO solution; draw 70μl of perovskite solution, spin-coat at 3000r / min for 120s, add 1...

Embodiment 2

[0053] The preparation method of the top-emitting silicon-based perovskite light-emitting diode provided in this embodiment is as follows:

[0054] a. Use an ultrasonic cleaner to clean and dry the silicon wafer;

[0055] b. Evaporate a layer of Cr metal layer on the surface of the cleaned silicon wafer with a thickness of 30nm and a rate of 0.3A° / s; then evaporate a layer of Au metal layer with a thickness of 50nm and a rate of 0.6A° / s;

[0056] c. Prepare a layer of MoO on the bottom metal electrode by magnetron sputtering 3 A transition layer with a thickness of 5nm and a rate of 0.3A° / s;

[0057] d. Take 85μl of PEDOT:PSS solution, set the spin coating speed to 2500r / min, time 40s, and anneal at 150℃ for 15min;

[0058] e. Weigh 80.8 mg of phenethyl ammonium bromide, 4.0 mg of methyl ammonium chloride, 50.0 mg of methyl ether ammonium bromide, and 220.2 mg of PbBr 2 Dissolve in 1ml of DMSO solution; draw 70μl of perovskite solution, spin-coat at 3000r / min for 120s, add ...

Embodiment 3

[0064] a. Use an ultrasonic cleaner to clean and dry the silicon wafer;

[0065] b. Evaporate a layer of Cr metal layer on the surface of the cleaned silicon wafer with a thickness of 30nm and a rate of 0.3A° / s; then evaporate a layer of Au metal layer with a thickness of 50nm and a rate of 0.6A° / s;

[0066] c. Take 85μl of PEDOT:PSS solution, set the spin coating speed to 2500r / min, time 40s, and anneal at 150℃ for 15min;

[0067] d. Weigh 80.8 mg of phenethyl ammonium bromide, 4.0 mg of methyl ammonium chloride, 50.0 mg of methyl ether ammonium bromide, and 220.2 mg of PbBr 2 Dissolve in 1ml of DMSO solution; draw 70μl of perovskite solution, spin-coat at 3000r / min for 120s, add 100μl of chlorobenzene solvent dropwise at 40s, and anneal at 90°C for 1h after spin-coating; absorb 50μl 2mg / ml TPPO solution, spin coating speed 7000r / min, time 1min;

[0068] e. Evaporate a TPBi electron transport layer on the perovskite light-emitting layer and the modified layer, with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com