X-ray detector suitable for high-temperature environment and preparation method thereof

A high-temperature environment, X-ray technology, applied in the field of high-temperature environment X-ray detectors and their preparation, can solve the problems of reduced resistivity, many structural defects, and device heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

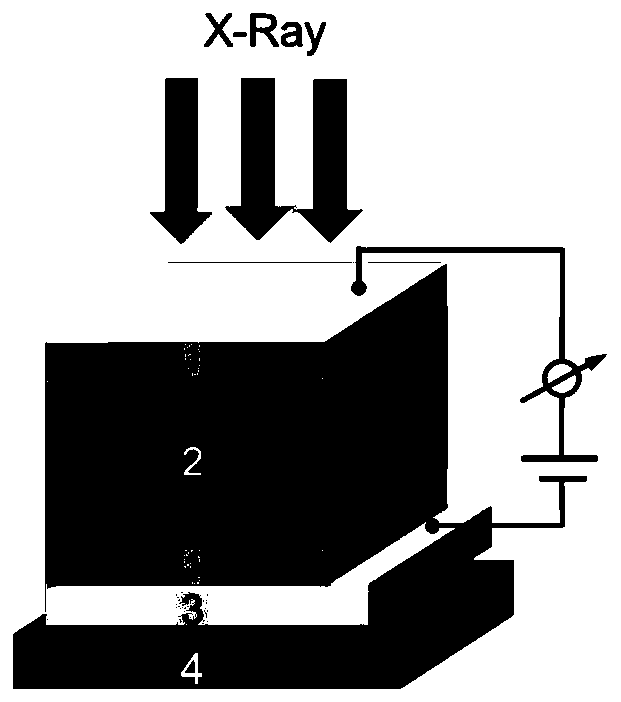

[0030] A preparation method of an X-ray detector suitable for a high temperature environment of the present invention comprises the following steps:

[0031] Step 1, put A 3 Bi 2 X 9 Type all-inorganic bismuth-based halide perovskite single crystal cut into the required size, where A is Cs + and Rb + One of them; X is I - , Br - and Cl - one or more of the mixture;

[0032] Step 2, put the cut A 3 Bi 2 X 9 Type perovskite single crystal for cleaning and surface polishing;

[0033] Step 3, A obtained in step 2 3 Bi 2 X 9 Metal electrodes were evaporated at both ends of the perovskite single crystal to obtain metal electrodes, A3 Bi 2 X 9 X-ray detector with layered perovskite single crystal and metal electrode.

[0034] Among them, A 3 Bi 2 X 9 The all-inorganic bismuth-based halide perovskite single crystal was obtained by the following method:

[0035] Step 1.1, according to the molar ratio, the bismuth halide BiX 3 and inorganic halide salt AX to configu...

Embodiment 1

[0041] An X-ray detector suitable for high temperature environment is made by the following steps:

[0042] Step 1, the molar ratio of BiI of 2:3 3 and CsI were dissolved in 30mL of DMF solvent, and configured into 0.8M Cs 3 Bi 2 I 9 precursor solution. The all-inorganic Cs can be obtained by placing the precursor solution in a 70°C oven, and gradually raising the temperature to 100°C at a heating rate of 6°C / day. 3 Bi 2 I 9 perovskite single crystal;

[0043] Step 2, cutting the obtained crystal with diamond yarn along the crystal plane to obtain several crystals with a thickness of 1.2 mm;

[0044] Step 3, will get the small size Cs 3 Bi 2 I 9 The single crystal is polished on sandpaper;

[0045] Step 4, in Cs 3 Bi 2 I 9 Gold electrodes are evaporated on both ends of the crystal;

[0046] Step 5, the obtained Au / Cs 3 Bi 2 I 9 / Au device is fixed on conductive glass with silver paste;

[0047] Step 6, a thermocouple thermometer is connected to the bottom of...

Embodiment 2

[0050] An X-ray detector suitable for high temperature environment is made by the following steps:

[0051] Step 1, the molar ratio of BiI of 2:3 3 and CsI were dissolved in 30mL of DMF / DMSO (7:3) mixed solvent to prepare 0.8M Cs 3 Bi 2 I 9 precursor solution. The all-inorganic Cs can be obtained by placing the precursor in an oven at 80°C and gradually raising the temperature to 120°C at a heating rate of 6°C / day. 3 Bi 2 I 9 perovskite single crystal;

[0052] Step 2, cutting the obtained crystal with diamond yarn along the crystal plane to obtain several crystals with a thickness of 1.2 mm;

[0053] Step 3, will get the small size Cs 3 Bi 2 I 9 The single crystal is polished on sandpaper;

[0054] Step 4, in Cs 3 Bi 2 I 9 Ag electrodes are evaporated on both ends of the crystal;

[0055] Step 5, the obtained Ag / Cs 3 Bi 2 I 9 / Ag device is fixed on conductive glass with silver paste;

[0056] Step 6, a thermocouple thermometer is connected to the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com