A kind of nano silicon dioxide/decomposition enzyme/polycaprolactone composite microsphere and its preparation method and application

A technology of nano-silica and polycaprolactone, applied in the field of medical materials, can solve the problems of easy-to-failure enzymes, accelerate the degradation rate of polylactic acid, and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

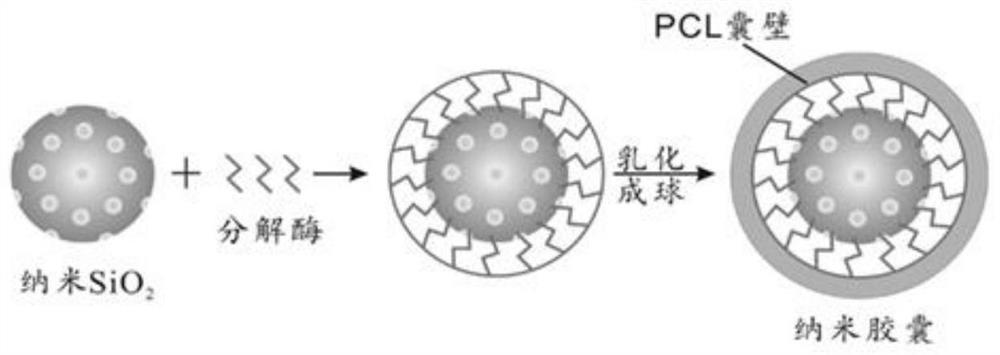

[0041] The present invention provides a method for preparing the composite microspheres described in the above scheme, comprising the following steps:

[0042] (1) Mixing nano-silica, decomposing enzyme, anionic surfactant, dispersant and water, stirring the obtained mixed solution, ultrasonic treatment and static adsorption in order to obtain a silica / decomposing enzyme complex;

[0043] (2) mixing the silica / decomposing enzyme complex, anionic surfactant, dispersant and water to obtain a silica / decomposing enzyme complex dispersion;

[0044] (3) adding the silica / decomposing enzyme complex dispersion into the polycaprolactone solution for the first emulsification treatment to obtain the first emulsion; the solvent of the polycaprolactone solution is dichloromethane;

[0045] (4) adding the first emulsion to a mixed solution of a dispersant and an anionic surfactant to perform a second emulsification treatment to obtain a second emulsion;

[0046] (5) remove the dichlorometh...

Embodiment 1

[0063] Reagents: polycaprolactone, molecular weight 45,000, Natureworks, USA; nano-silica, Jiangsu Tianxing New Material Co., Ltd., particle size: 20nm; lipase, Sigma, USA, L3126, activity: 30-90U / mg; polyethylene Diol, molecular weight 4000, pharmaceutical grade, Shandong Youso Chemical Technology Co., Ltd.; sodium dodecylbenzenesulfonate, dichloromethane, phosphate buffer (Hubei Wanye Pharmaceutical Co., Ltd., pH7.4, reagent grade).

[0064] Preparation steps:

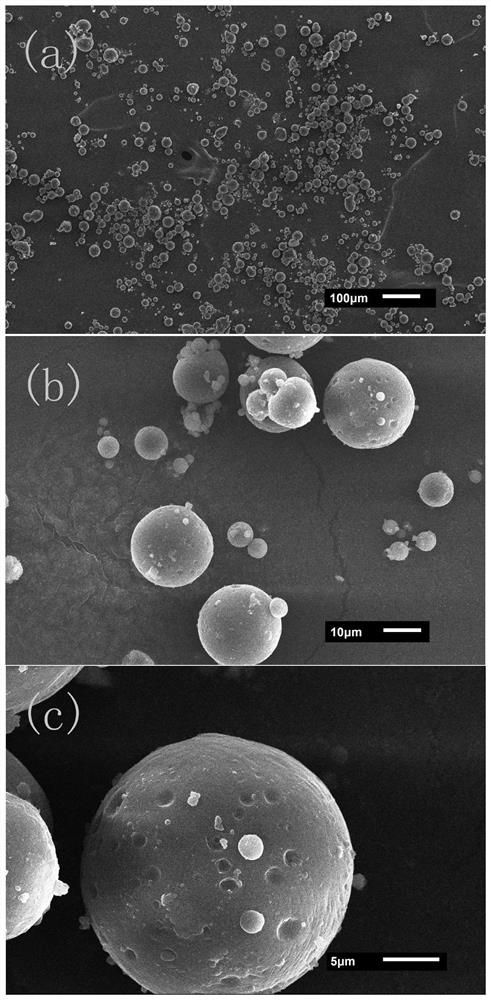

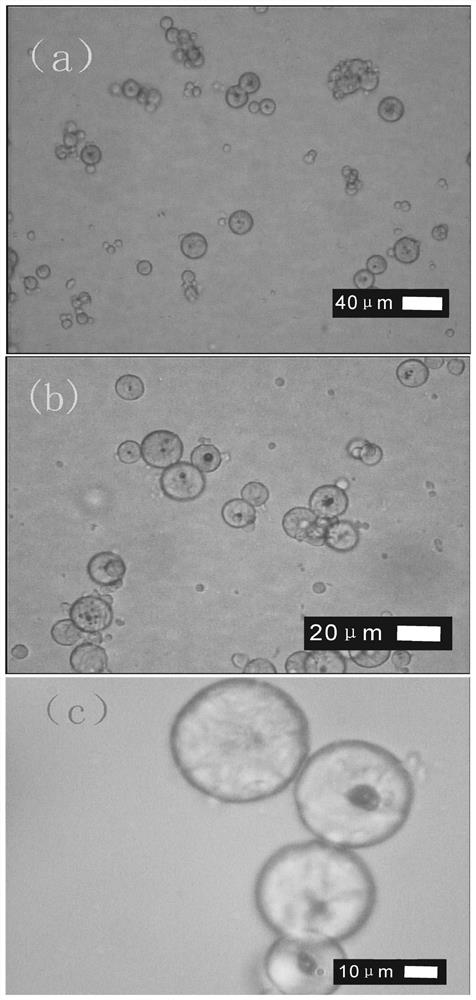

[0065] (1) Preparation of nano-silica / lipase complex

[0066] Weigh 0.5g of nano-silica, 0.5g of lipase, 0.5g of sodium dodecylbenzenesulfonate and 2g of polyethylene glycol and dissolve them in water to form a 500mL mix of nano-silica / lipase solution. The prepared above-mentioned solution was placed in an intelligent digital display magnetic electric heating mantle for magnetic stirring for 15 minutes, and then placed in an ultrasonic cleaner for ultrasonic treatment for 20 minutes. Stand still for 24 hours to co...

Embodiment 2

[0084] The other steps are the same as in Example 1, only controlling the concentration of the nano-silica / lipase complex dispersion in step (2) to be 0.3 mg / mL to obtain the core material and capsule wall quality Composite microspheres with a ratio of 3:50;

[0085] Other steps are the same as in Example 1, only controlling the concentration of the nano-silica / lipase complex dispersion in step (2) to be 0.5mg / mL to obtain the core material and capsule wall quality Composite microspheres with a ratio of 5:50;

[0086] The other steps are the same as in Example 1, only controlling the concentration of the nano-silica / lipase complex dispersion in step (2) to be 0.7mg / mL to obtain the core material and capsule wall quality Composite microspheres with a ratio of 7:50;

[0087] The other steps are the same as in Example 1, only controlling the concentration of the nano-silica / lipase complex dispersion in step (2) to be 0.9 mg / mL to obtain the core material and capsule wall mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com