Antibacterial and hemostatic multifunctional composite hydrogel dressing and preparation method thereof

A composite hydrogel and hydrogel technology, applied in pharmaceutical formulations, pharmaceutical science, drug delivery, etc., can solve the problems of poor hemostatic effect and low strength of hemostatic gel, and achieve inhibition of wound infection, excellent antibacterial properties, high The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

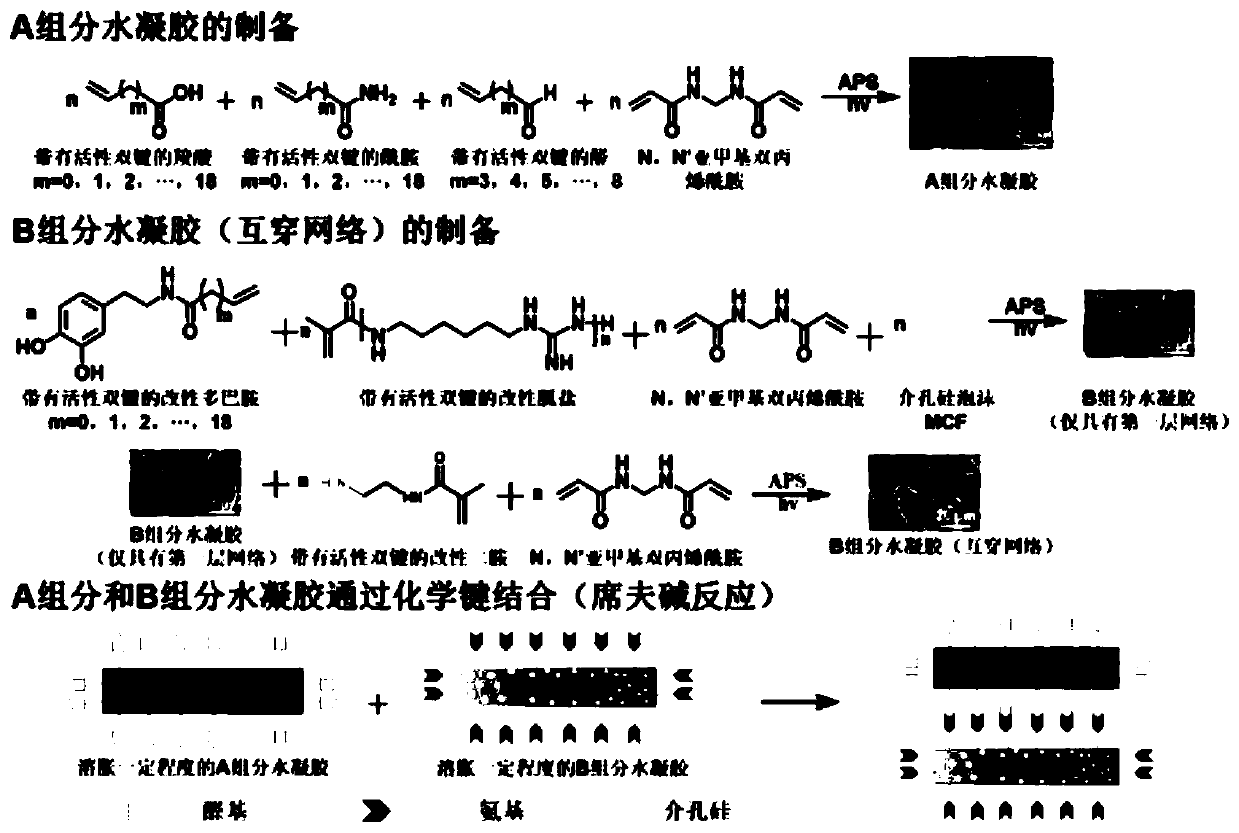

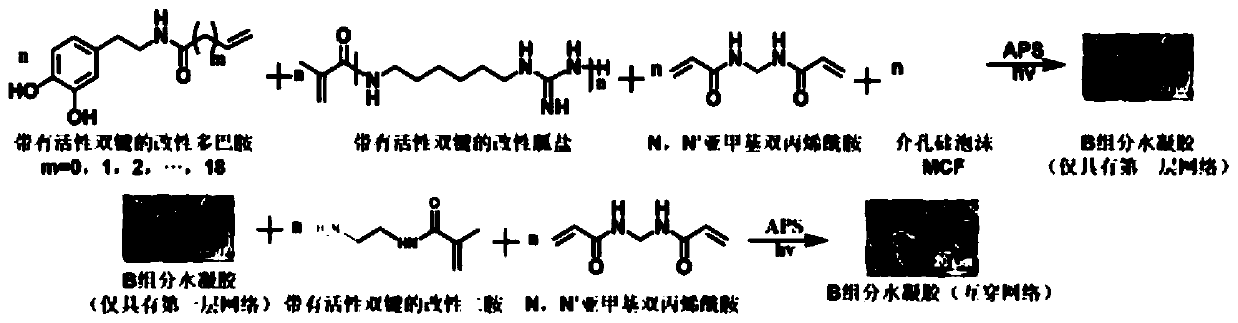

[0031] The preparation method of the above-mentioned antibacterial and hemostatic multifunctional composite hydrogel dressing comprises the following steps:

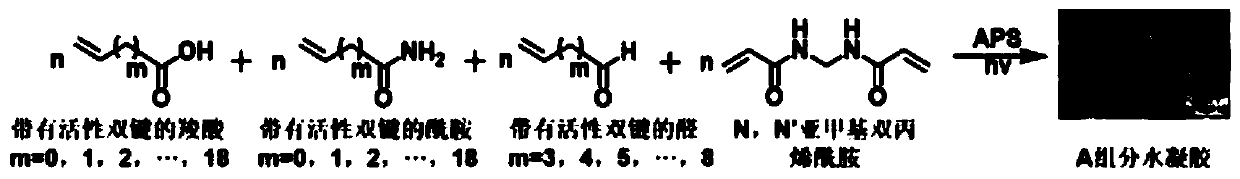

[0032] Step 1): the preparation of component A hydrogel: dissolve carboxylic acid or sodium carboxylic acid salt with active double bond, amide with active double bond and aldehyde with active double bond in deionized water and Stir and mix well, slowly add NaOH aqueous solution with a mass concentration of 10-30% for neutralization, and control the temperature of the reaction system below 30°C to prevent carboxylic acids or sodium carboxylic acid salts with active double bonds; after neutralization , add a double bond cross-linking agent to the reaction system, and add persulfate to initiate polymerization, the obtained hydrogel swells in distilled water, change the water several times, remove unreacted monomers, cross-linking agents and initiators; take out the water The gel is freeze-dried to obtain component A hydrog...

Embodiment 1

[0041] Preparation of component A hydrogel: in parts by mass, the raw material components include: 100 parts of acrylic acid, 100 parts of acrylamide, 30 parts of citronellal, 10000 parts of deionized water, 100 parts of NaOH aqueous solution with a mass concentration of 20%, 1 part of double bond crosslinking agent, 1 part of persulfate. Dissolve acrylic acid, acrylamide and citronellal in deionized water and fully stir and mix, slowly add NaOH aqueous solution with a mass concentration of 20% to neutralize (control the temperature of the reaction system below 30°C to prevent self-polymerization of acrylic acid), after neutralization , add N,N'-methylenebisacrylamide to the reaction system, and add ammonium persulfate to initiate polymerization, the obtained hydrogel is swollen in distilled water, and the water is changed several times to remove unreacted monomers and crosslinking agents with initiator. The hydrogel was taken out and subjected to freeze-drying treatment to o...

Embodiment 2

[0045] Preparation of component A hydrogel: in parts by mass, the raw material components include: 100 parts of methacrylic acid, 100 parts of acrylamide, 30 parts of citronellal, 10000 parts of deionized water, and 100 parts of NaOH aqueous solution with a mass concentration of 20%. 1 part, 1 part of double bond crosslinking agent, 1 part of persulfate. Dissolve methacrylic acid, acrylamide and citronellal in deionized water and fully stir and mix, slowly add NaOH aqueous solution with a mass concentration of 20% for neutralization (control the temperature of the reaction system below 30°C to prevent self-polymerization of acrylic acid), neutralize After completion, N,N'-methylenebisacrylamide was added to the reaction system, and ammonium persulfate was added to initiate polymerization. The obtained hydrogel was swollen in distilled water, and the water was changed several times to remove unreacted monomers and cross-linked gels. Liaisons and initiators. The hydrogel was ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com