Nickel telluride microsphere and preparation method and application thereof

A technology of nickel ditelluride and microspheres, applied in chemical instruments and methods, selenium/tellurium compounds, metal selenides/tellurides, etc., can solve problems such as poor photocatalytic stability, low light absorption coefficient, and small specific surface area , to achieve uniform morphology, high hydrogen production rate, and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing nickel ditelluride microspheres, comprising the following steps:

[0028] After mixing tellurium powder, dodecanethiol and oleylamine, ultrasonic treatment is performed to obtain a tellurium precursor solution;

[0029] After mixing nickel salt, octadecene, oleylamine and oleic acid, heating and dissolving to obtain a nickel source solution;

[0030] The tellurium precursor solution is mixed with the nickel source solution for reduction reaction to obtain nickel ditelluride microspheres.

[0031] In the invention, tellurium powder, dodecanethiol and oleylamine are mixed, and subjected to ultrasonic treatment to obtain a tellurium precursor solution.

[0032] In the present invention, there is no special limitation on the specifications of the tellurium powder, and commercially available tellurium powder can be used.

[0033] In the present invention, the ratio of the amount of tellurium powder to dodecanethiol is preferabl...

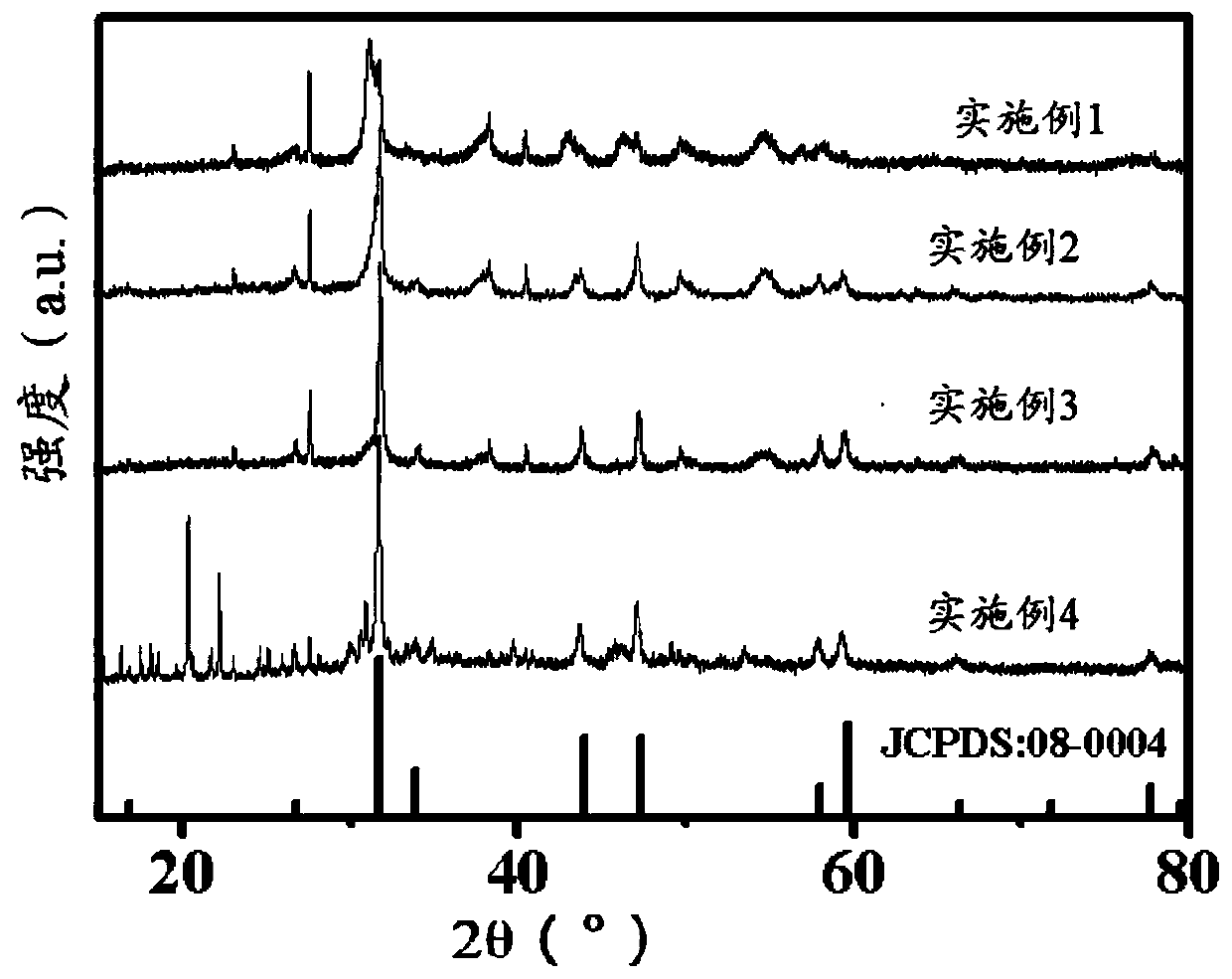

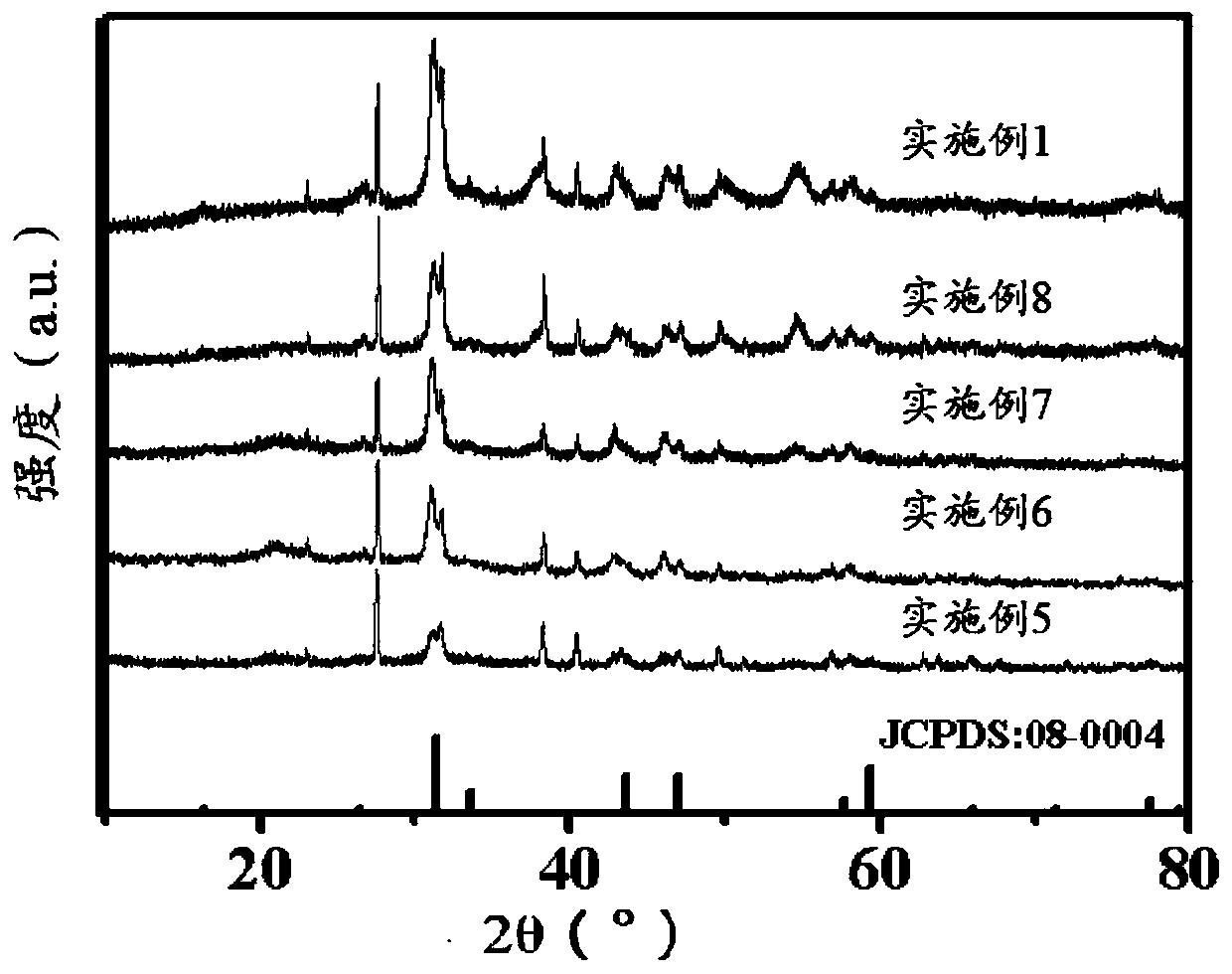

Embodiment 1

[0049]Mix 0.0478g of tellurium powder with 0.3mL of dodecanethiol and 1.7mL of oleylamine, and then ultrasonically treat it for 20min at a power of 80W to obtain a tellurium precursor solution;

[0050] Mix 15mL of octadecene, 10mL of oleylamine, 0.25mL of oleic acid and 0.0642g of nickel acetylacetonate, stir for 5 minutes under a nitrogen atmosphere to form a suspension, then raise the temperature to 175°C and heat to dissolve. After the nickel acetylacetonate is dissolved, you can get Nickel source solution;

[0051] The tellurium precursor solution was added dropwise to the nickel source solution, reacted at 175°C for 30 minutes, then cooled to room temperature, washed with chloroform and ethanol for three times, and then dried to obtain nickel ditelluride microspheres.

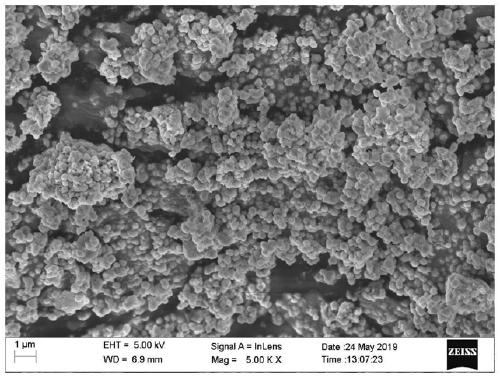

[0052] It is measured that the average particle diameter of the nickel ditelluride microspheres obtained in this embodiment is 300 nm.

Embodiment 2

[0054] Nickel ditelluride microspheres were prepared according to the method of Example 1, except that the temperature for heating, dissolving and reacting was 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com