Preparation process of artificial bear gall powder

A production process, technology of bear bile powder, applied in the field of biomedicine, can solve problems such as high cost, difficulty in maintaining enzyme activity, complicated enzyme purification steps, etc., and achieve the effects of increasing content, improving efficiency, and low viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

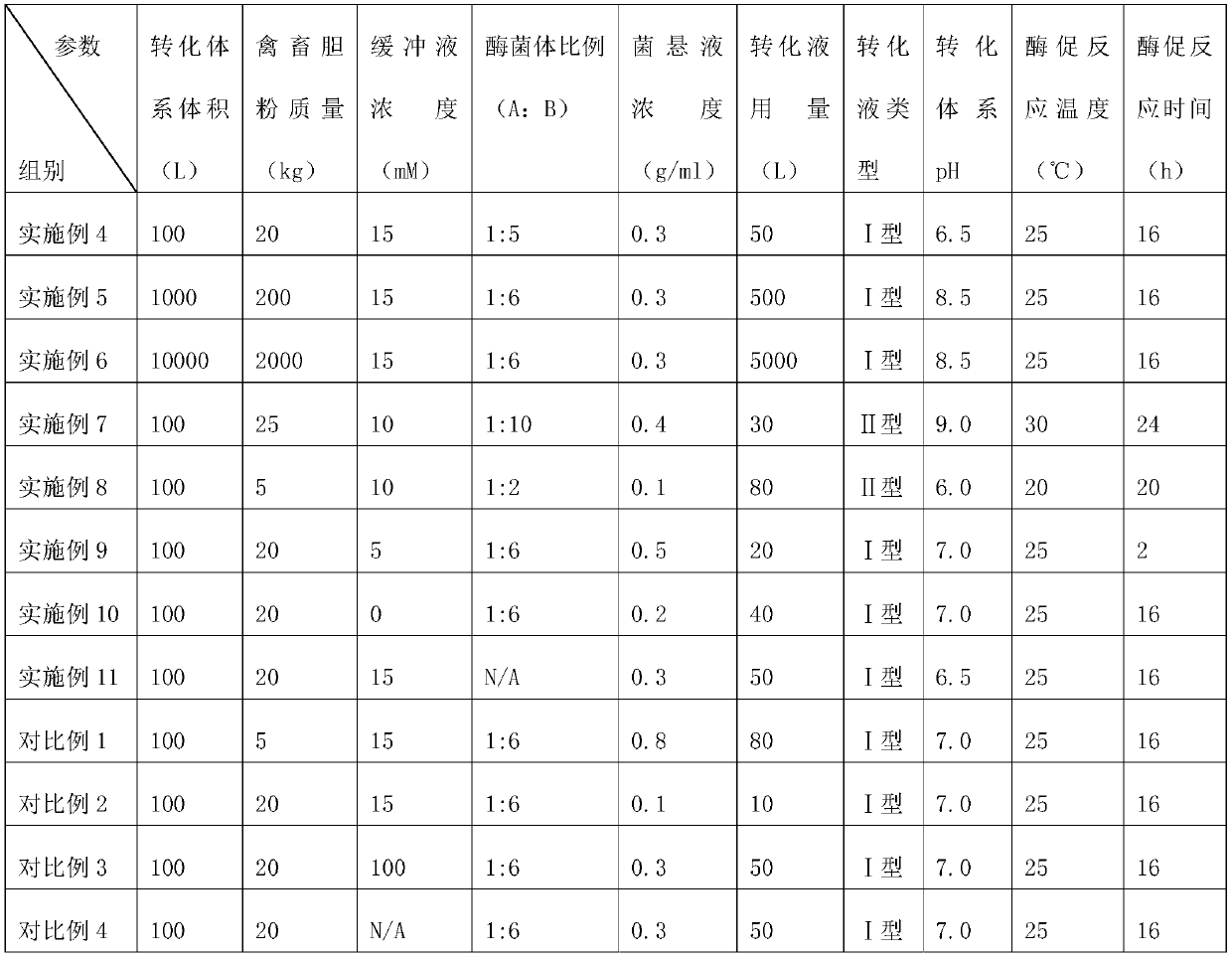

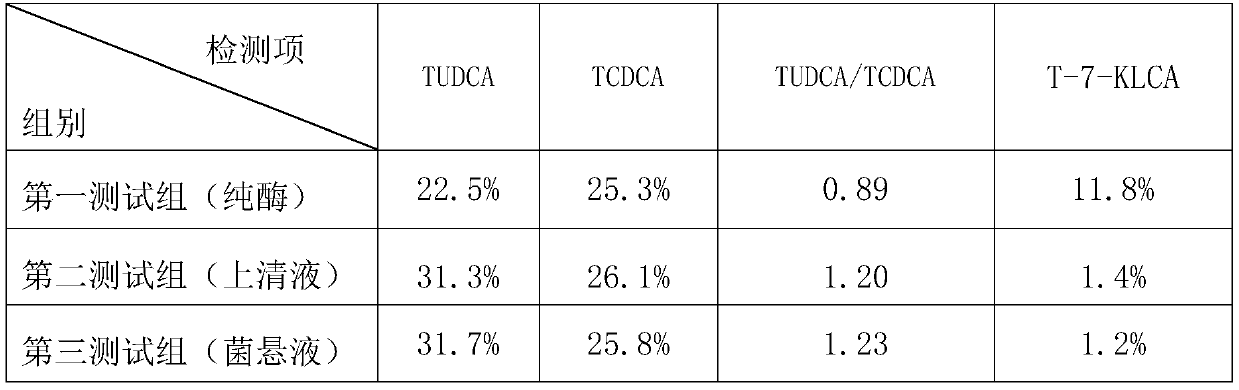

Examples

Embodiment 1

[0035] Example 1: Preparation of engineering bacteria

[0036] The 7α-hydroxysteroid dehydrogenase gene S1-a-1 and the 7β-hydroxysteroid dehydrogenase gene Y1-b-1 were codon-optimized for expression in E. coli, and affinity tags were added, and the whole gene was synthesized. The optimized 7α-hydroxysteroid dehydrogenase gene S1-a-1 is abbreviated as 7α-steroid dehydrogenase gene in this paper, and denoted as 7α-HSDH (SEQ ID NO: 1); the optimized 7β-hydroxysteroid dehydrogenase The gene Y1-b-1 is abbreviated as 7β-steroid dehydrogenase gene herein, and is denoted as 7β-HSDH (SEQ ID NO: 3).

[0037] 1. Construction of Expression Vectors

[0038] a) Preparation of recombinant plasmid pET28a-7α-HSDH containing 7α-steroid dehydrogenase gene

[0039] 7α-HSDH (DNA sequence: SEQ ID NO: 1, encoded protein sequence: SEQ ID NO: 2) was prepared with primer pairs 5′-GGAATTCCATATGGGCAGCAGCCATCATCA-3′ (SEQ ID NO: 5) and 5′-TCCCTCGAGTTAACGGCTGCGCTCCATCAT-3 ' (SEQ ID NO: 6) was amplified b...

Embodiment 2

[0047] Example 2: Fermentation expression of engineered bacteria

[0048] (1) Preparation of strains

[0049] The bacterial solutions of engineering bacteria A and engineering bacteria B are respectively coated with kana-resistant LB plates, and the bacterial solutions of engineering bacteria C are coated with ampicillin-resistant LB plates. In LB medium of kana or ampicillin, 37 ° C, 220 rpm, culture, when the OD value is 0.8-1.2, add 1 mM IPTG to induce 2 h, detect the expression level by SDS-PAGE, and select clones with high expression levels as intermediate strains (Intermediate strain A, intermediate strain B and intermediate strain C) are preserved.

[0050] Take 20 μL of Escherichia coli BL21 (DE3) strains (three intermediate strains: intermediate strain A, intermediate strain B and intermediate strain C) containing the recombinant plasmid, inoculated into 200 mL of kana- or ampicillin-resistant LB medium, respectively Medium, 37°C, 220rpm, overnight culture, OD 600 ...

Embodiment 3

[0054] Example 3: Preparation of poultry bile powder

[0055] The technical route for the preparation of poultry gall powder is: cut fresh poultry gall bladder or thawed poultry gall bladder with a meat grinder, pass through a 100-mesh sieve to get the liquid phase part (mainly bile), and add 90-95 g of the liquid phase part. % ethanol to a final concentration of 60-85% ethanol, centrifugation or filtration to remove the precipitate, and the supernatant is concentrated under reduced pressure and vacuum-dried to obtain avian gall powder.

[0056]Specifically in this embodiment: take 20Kg of thawed chicken gallbladder, cut it with a meat grinder, filter with a 100-mesh stainless steel filter screen and a multi-layer 100-mesh nylon mesh, take the liquid phase, and decompress the liquid phase to remove water to paste (density controlled at 1.10±0.05g / ml), add 25L of 95% ethanol to the paste and mix it overnight, centrifuge at 3800rpm for 5min to remove the precipitation, the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com