Conductive paste for positive electrode of solar cell as well as preparation method and application thereof

A technology for solar cells and conductive pastes, which is applied to equipment for manufacturing conductive/semiconductor layers, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc. The problems of sheet cutting process and tensile force can not meet the requirements, so as to avoid printing defects, improve printability and high battery conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

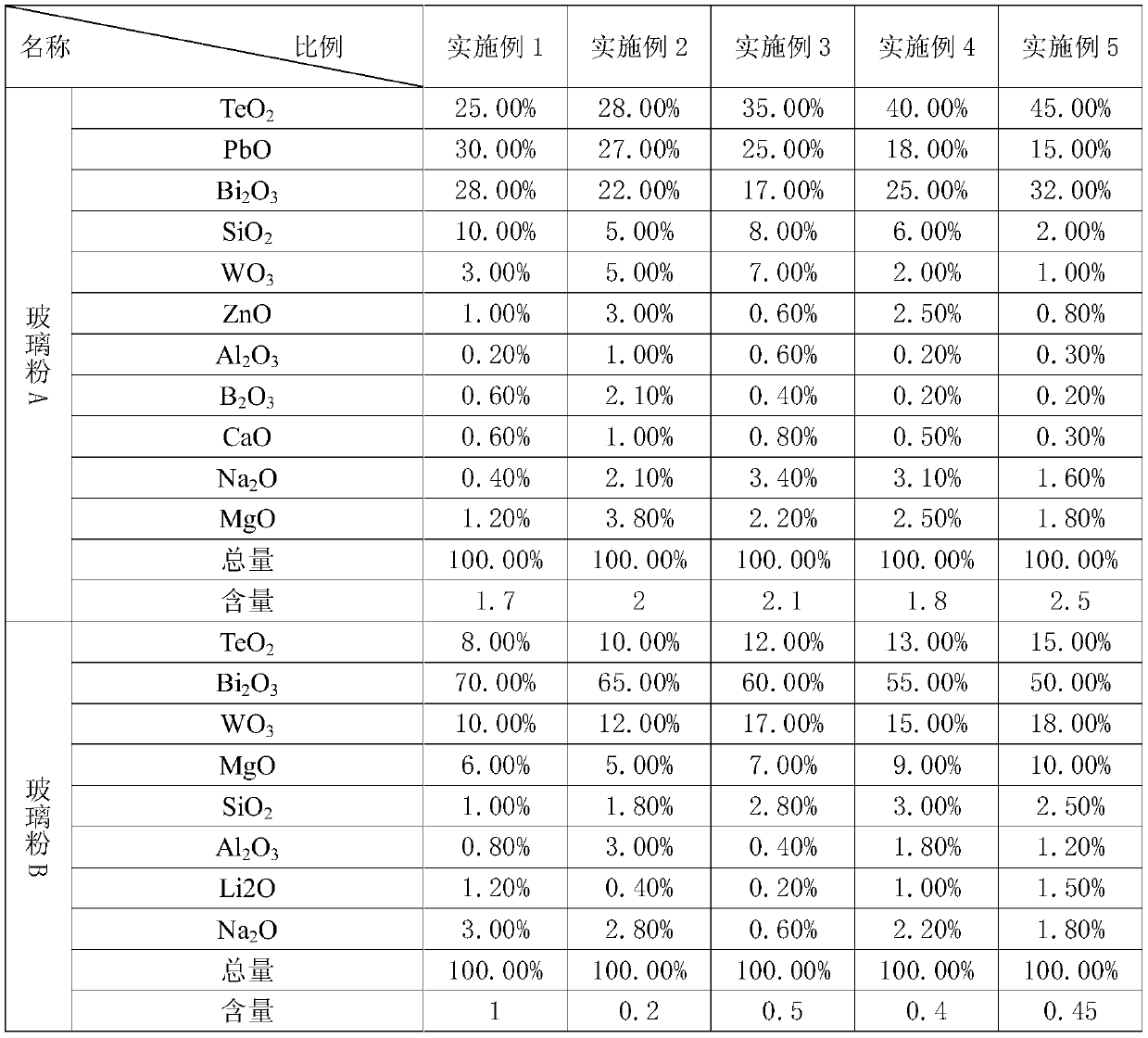

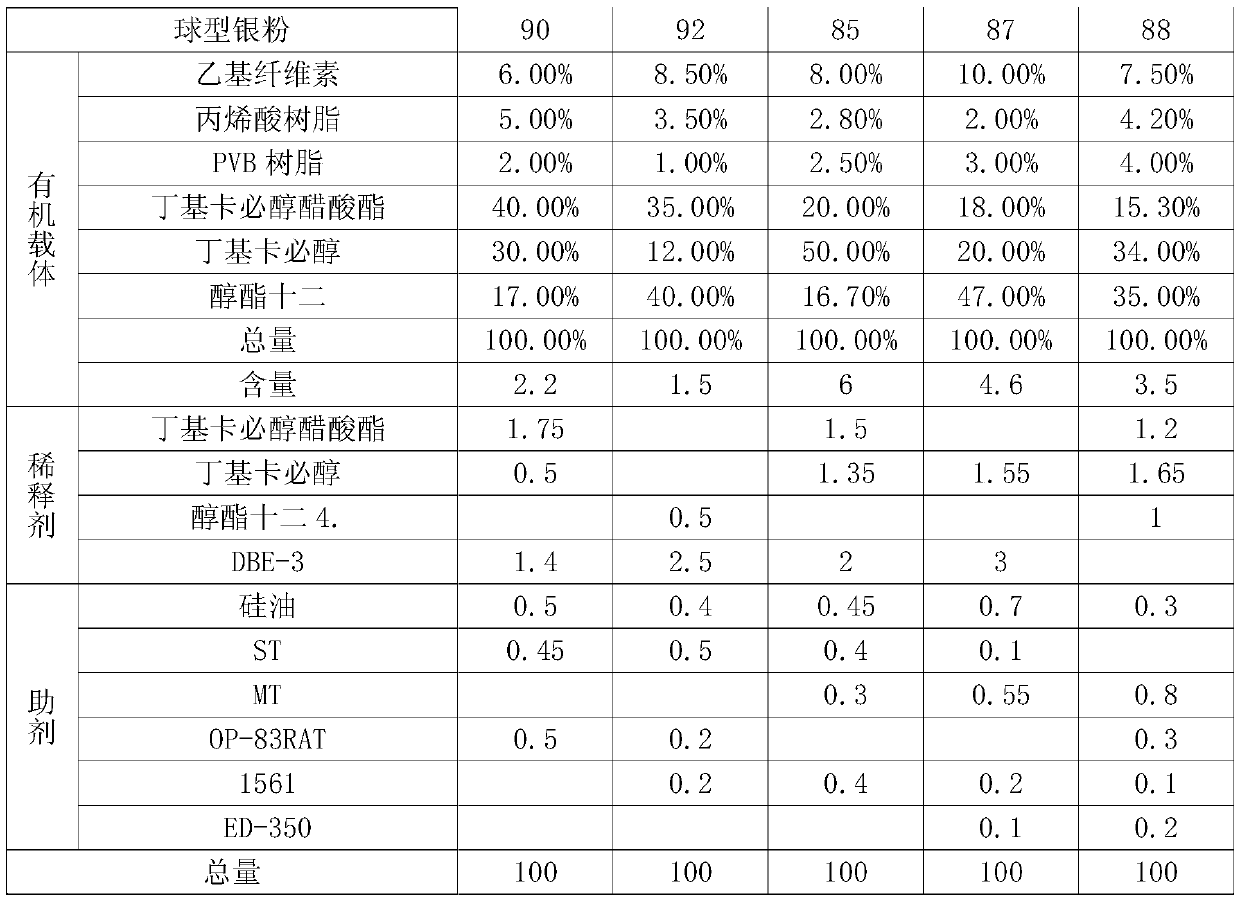

[0055] The conductive paste adopted in this embodiment adopts the following formula: 1.7% glass powder A, 1% glass powder B, 90% spherical silver powder, 2.2% organic vehicle, 3.65% diluent, 1.45% auxiliary agent, its specific formula composition As shown in Table 1.

[0056] Its preparation method specifically comprises the following steps:

[0057] A1) prepare glass powder A and glass powder B:

[0058] A11) According to the raw materials and ratios shown in Table 1, TeO 2 , PbO, Bi 2 o 3 , SiO 2 、WO 3 , ZnO, Al 2 o 3 , B 2 o 3 , CaO, Na 2 Mix O and MgO evenly, melt after heating, cool, ball mill, and sieve to obtain glass powder A. The D50 of the glass powder is preferably 1.8 μm.

[0059] A12) According to the raw materials and ratio shown in Table 1, TeO 2 、 Bi 2 o 3 、WO 3 , MgO, SiO 2 、Al 2 o 3 , Li 2 O, Na 2 O is mixed evenly, heated, melted, cooled, ball milled, and sieved to obtain glass powder B. The D50 of the glass powder is preferably 1.6 μm. ...

Embodiment 2

[0065] The conductive paste adopted in this embodiment adopts the following formula: 2% glass powder A, 0.2% glass powder B, 92% spherical silver powder, 1.5% organic vehicle, 3% diluent, 1.3% auxiliary agent, its specific formula composition As shown in Table 1. Its preparation method is basically the same as that of Example 1, so it will not be described in detail one by one.

Embodiment 3

[0067] The conductive paste adopted in this embodiment adopts the following formula: 2.1% glass powder A, 0.5% glass powder B, 85% spherical silver powder, 6% organic vehicle, 4.85% diluent, 1.55% auxiliary agent, its specific formula components As shown in Table 1. Its preparation method is basically the same as that of Example 1, so it will not be described in detail one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com